What does the expansion and contraction of dismantling joints represent?

Dismantling joints are important equipment to protect pipes during the process of pipe connection. After a lot of experience in using dismantling joints, the life of pipes with dismantling joints is about twice as long as those without dismantling joints, therefore, dismantling joints are not only connecting pipes, but also protecting pipes is their important feature.

Each disassembly joint can be freely extended or shortened. When the pipe is heated and expanded, the disassembly joint will be shortened, and when the pipe is cooled and shortened, the disassembly joint will be lengthened to compensate for the expansion. Therefore, whether the pipeline becomes longer or shorter, the disassembly joint will take care of it, and the pipeline will not be affected in any way, so that the pipeline can be protected.

The disassembly joint is specially existed to protect the pipeline from thermal expansion and contraction. When a pipe is heated or cold, the length of the pipe will be elongated or shortened by a small amount, which is very small, but if every connected pipe is elongated or shortened at the same time, the expansion or contraction is relatively large and may lead to the pipe being squeezed or torn off at the pipe joint.

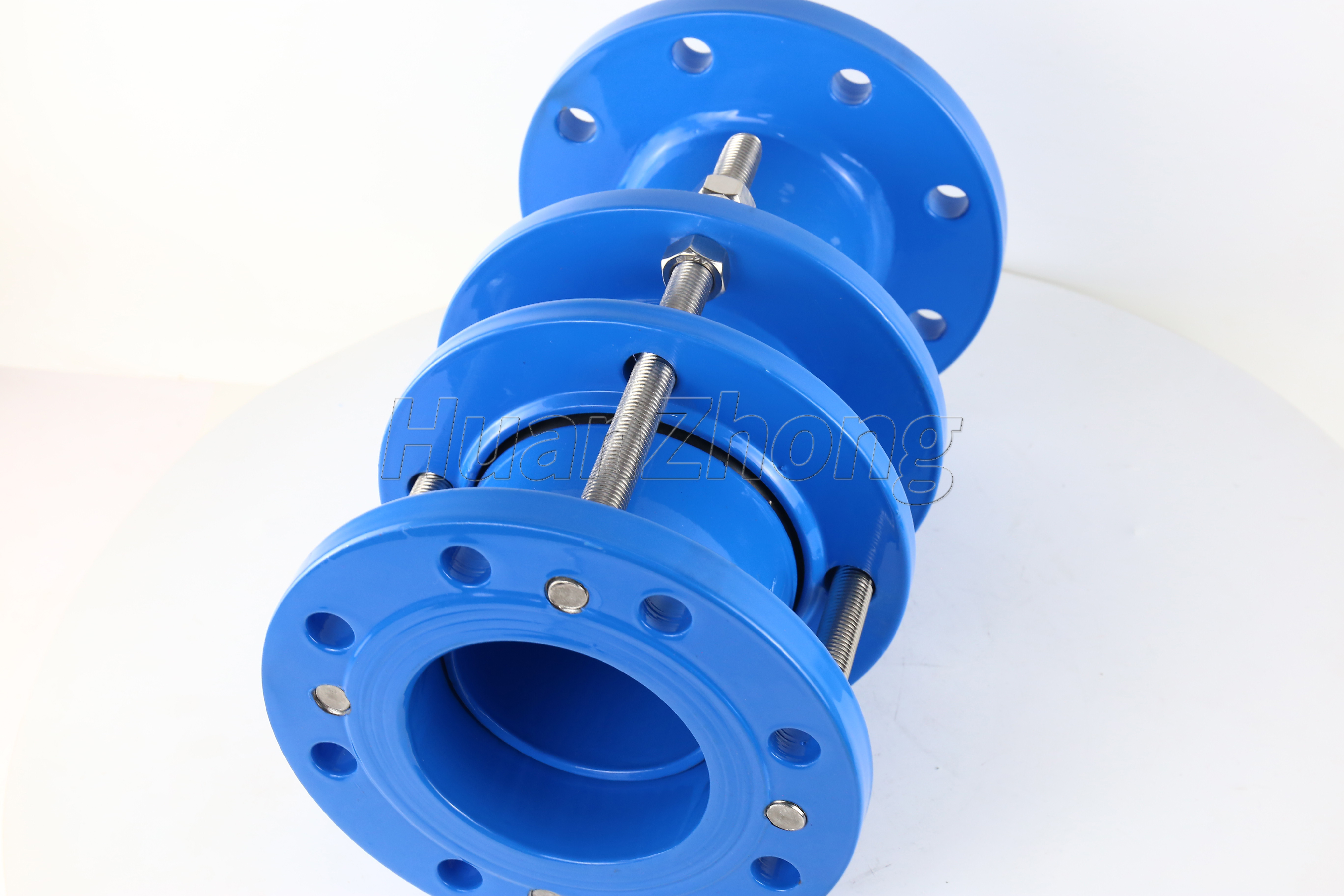

A disassembly joint is a pipe joint with a certain amount of expansion and contraction. It means that there can be a certain amount of distance between the two ends of the joint, and it can be freely extended or shortened within the distance allowed. Of course, this expansion is relatively limited, and when the expansion is too large, it will make the limiting device work and reach a large expansion displacement.

In the process of pipeline use, it is inevitable to encounter thermal expansion and contraction. The pipeline will not be so obvious as rubber products when thermal expansion and contraction occurs, but when the pipeline is suddenly in a hot or cold state, it is likely that the pipeline will suddenly become longer or shorter, which is harmful to the pipeline, and the disassembly joint, which is used to prevent the pipeline from being damaged due to thermal expansion and contraction.

BF type disassembly joint is suitable for connecting with flange on one side and welding with pipeline on the other side. When installing, adjust the installation length of both ends of the product and pipeline or flange, tighten the gland bolts evenly diagonally, and then adjust the nuts so that the pipeline can expand freely within the expansion range, lock the expansion and the operation of the pipeline.