Flexible rubber expansion joint rubber damage causes and solutions.

Flexible rubber expansion joint as a pipeline link for vibration and noise reduction of flexible joints, in the pipeline has been vigorously used, whether it is a construction pipeline or power plant pipeline, the unique high temperature resistance, corrosion resistance, aging resistance, oil resistance, etc., so that the flexible rubber expansion joint is very widely used.

Flexible rubber expansion joint pipeline construction and installation, must be allowed to be in a natural state, do not artificially in the installation of the product to produce artificial deformation. This can avoid causing early damage to the product and the use of the effect of weakening.

During the manufacturing or transportation of rubber expansion joints, the sealing surface of rubber expansion joints is damaged and, due to external forces, the sealing surface is not flat.

The pipe is exposed to the sun, and after exposure to the sun with the aging of time, the bendable rubber joint will have different degrees of cracking damage. The solution is to try not to let the product exposed to the sun for the wind and sun, if there is no way to wrap a few layers of plastic film around the outside of the product including up, can ease the aging time.

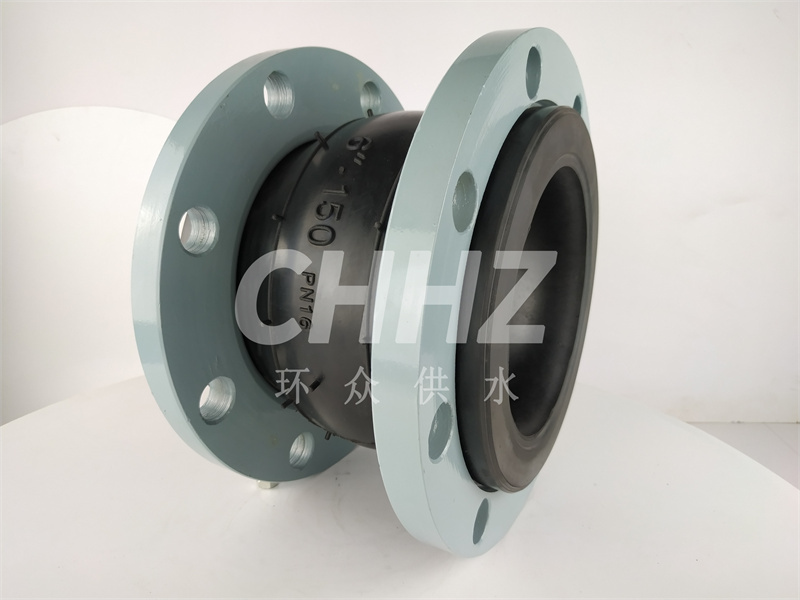

Flange rubber expansion joint in the installation, shall make the two ends of the sphere to enhance the ring (protruding part of the inner wire rope) all stuck into the flange groove, to prevent the pipeline pressure when the sphere and flange pull off. On the bolt, first tighten the symmetrical bolt to ensure that the sphere in the flange of all in place.

If leakage is found, first look at whether the bolts are not tightened, if this is ruled out, it is possible that the rubber joint sphere is damaged or there is a problem with the design of the sphere grinding tool, please replace the rubber joint immediately.

Rubber expansion joint surface foaming or deformation situation, the first statement is that it will not affect the performance of the product, do not need to be replaced, need more regular inspection patrol. However, if you see the separation of the rubber curtain layer of the rubber joint of the flange outer diameter above, the bendable rubber expansion joint should be replaced as soon as possible.