Does the sleeve compensator need to be equipped with a diversion tube?

Sleeve compensator price is high, the working conditions in the harsh environment, either toxic and harmful chemicals, or very corrosive types of acids and bases or organic solvents, improper use will produce significant economic losses and serious consequences. The correct use and maintenance of the sleeve compensator can extend the life of the sleeve compensator, to prevent all kinds of accidents, to protect the normal operation of the pipeline.

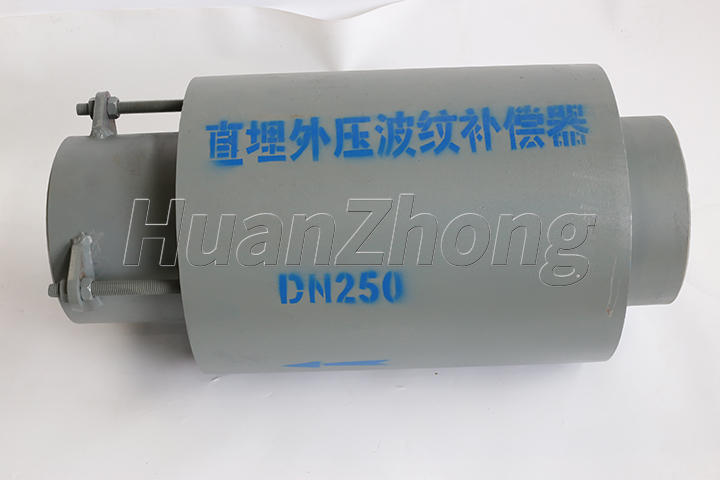

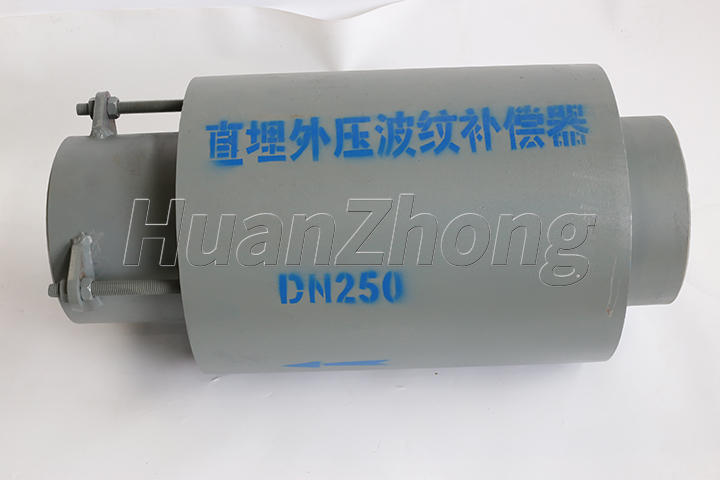

Decide according to the actual situation. Sleeve compensator adopts new type of sealing material flexible graphite ring, which has the characteristics of high strength, small friction coefficient, no aging, good effect, easy maintenance, etc. The sleeve compensator is mainly used for the auxiliary installation of linear pipeline. Sleeve compensator is suitable for hot water, steam, grease media, through the sliding sleeve to the outer sleeve of the sliding movement, to achieve the compensation of thermal expansion. With a small volume, the compensation volume is large. Widely used in urban heating, metallurgy, mining, power generation, petroleum, chemical, construction and other industries in the transport pipeline.

The service life of sleeve compensator is large, and the fatigue life is comparable to that of pipeline. The sliding surface is specially treated and has good corrosion resistance in salt water, salt solution and other environments, more than 50 times higher than stainless steel. At the same time, after many years due to wear and tear resulting in a weakening of the sealing effect, can again strengthen the flange to enhance the sealing performance, but also the bolt can be loosened, remove the pressure ring, and then installed into a layer or two sealing ring, tighten the pressure ring, continue to use. Sleeve compensator on the chloride ion content does not require, especially suitable for the medium or the surrounding environment chloride ion exceeds the standard system on.

For some media instability and easy decomposition (such as the decomposition of some media will cause volume expansion caused by abnormal pressure rise) will cause sleeve compensator damage or leakage, measures should be taken to eliminate or limit the factors that cause the decomposition of unstable media. In the sleeve compensator selection, should consider the media instability and easy decomposition may cause changes in working conditions and select the sleeve compensator with automatic pressure relief device.