The difference between full bolt and half bolt of double flange dismantling joint

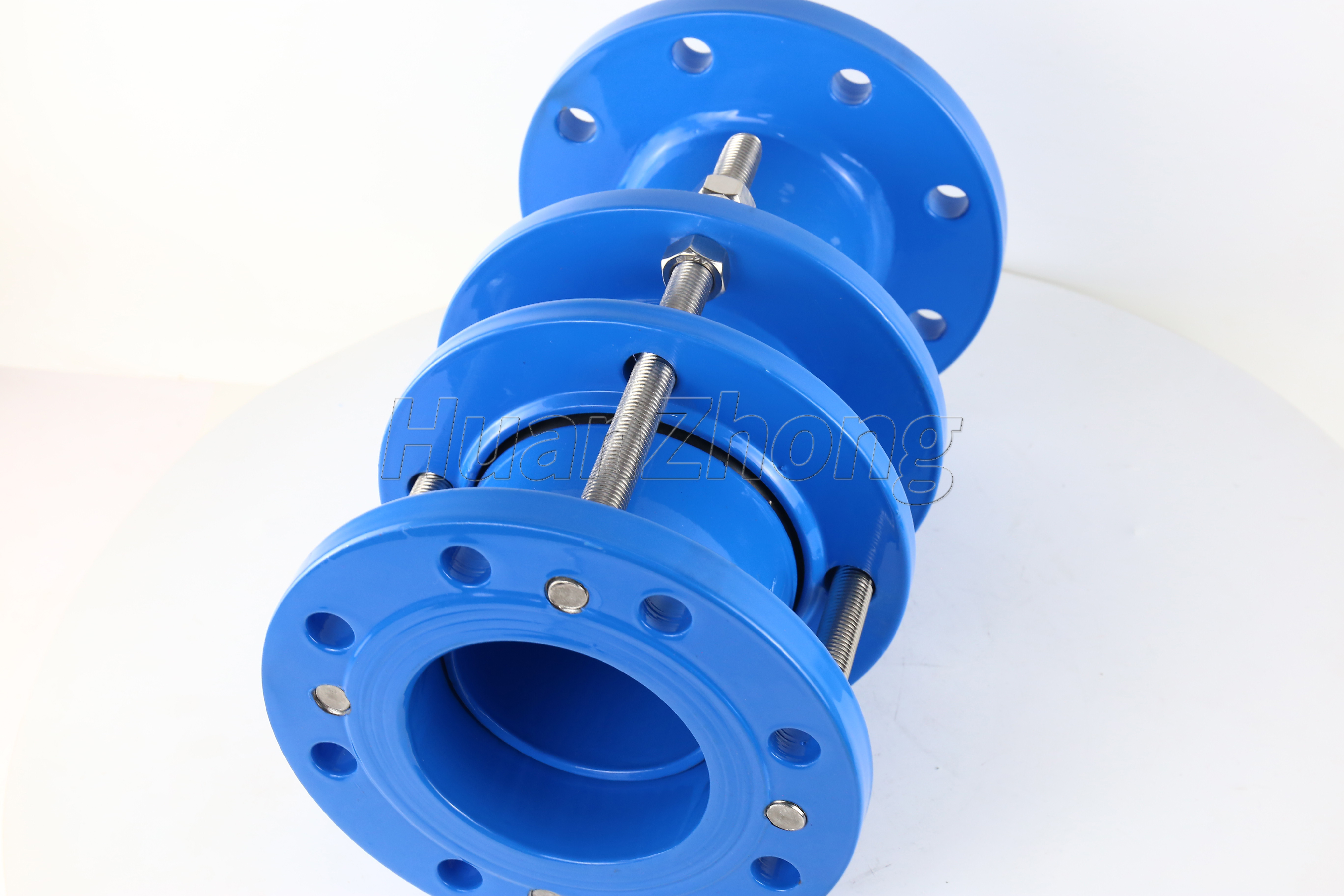

Double flange disassembly joint is suitable for pipeline system drainage system, conveying different media selection materials, double flange disassembly joint is made of gland, seal ring, valve body, short pipe flange, bolts and nuts and other combinations. The material is usually made of carbon steel, stainless steel and cast iron, which is suitable for conveying various media. The double flange disassembly joint mainly plays the role of force transmission compensation, which connects the two ends of the pipeline and is installed and used in various pipeline systems such as water supply pipelines.

The difference can be seen from the appearance. The advantage of all-threaded joints is that one bolt runs through the whole joint and can be connected to the pipeline by loosening the nut during installation, so there is no need to purchase additional fasteners and other devices for connection, saving a large part of the cost. In contrast, half-threaded force transfer joints require additional fasteners for installation. Half-threaded threads use fewer bolts and reduce costs, and when purchasing the product, it should be customized according to the condition of the pipeline.