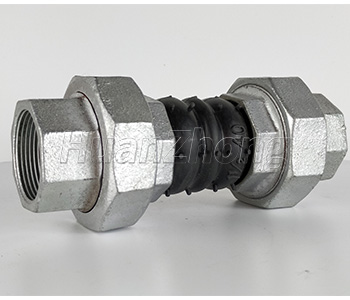

Threaded rubber joint is one kind of rubber joints of which connection is different from the usual flange rubber joints. Threaded rubber joint is of high elasticity and high air tightness, with good sex of medium and environmental resistance. Threaded rubber joint itself is depended on the advantages of elasticity of rubber ball, air tightness and so on; while internal adopt high strength to be effectively used for high temperature and low temperature polyester cord fabric composite interaction through vulcanization. The construction of the engineering tends to use the threaded rubber joint because of its advantages. It is widely used in the extraction of raw water and wastewater and transportation, water supply and cooling cycle of coal-fired power plants, metallurgical industry, condensed water industry, chemical industry and transport processing of various kinds of chemicals. Also it is used to connect with other pipes in the pipeline to reduce vibration and noise pollution. Because of the advantages of wear resistance of rubber itself, it is not just used as pipe connection in the liquid conveying, and also in the dust and powder and gas transport.