Introduction to the characteristics of rubber expansion joints used in centrifugal pumps

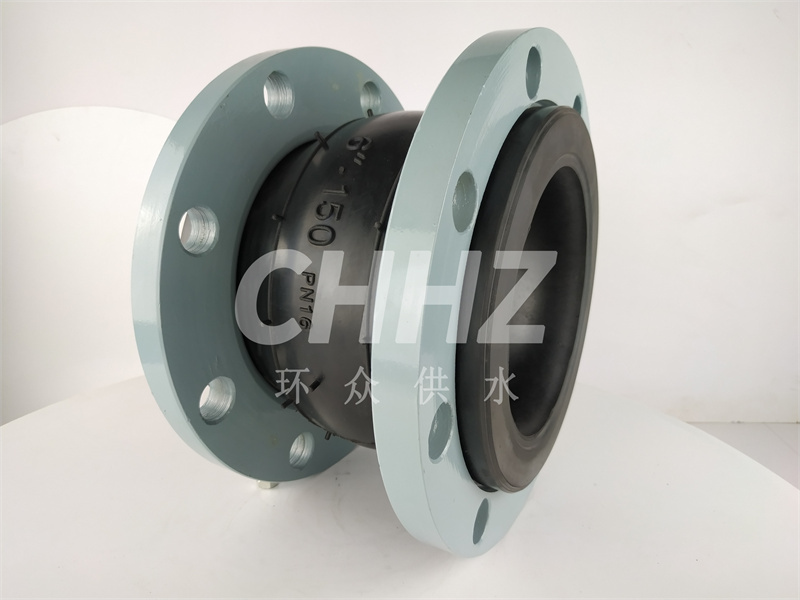

Rubber expansion joint is a special kind of elastic joint. Under normal circumstances, rubber products will not undergo any deformation, but under the action of external forces, deformation will occur. What are the characteristics of rubber joints in the process of use? Features? What characteristics does it have? Today we will briefly introduce: rubber joints consist of spheres, bushings, fixed nuts and flanges, which are mainly used for connection between various pipelines to eliminate pipeline displacement and vibration due to displacement; compensate pipeline axial displacement; expansion and compensation displacement; adjust verticality; reduce noise; vibration damping; anti-leakage and other functions.

Easy installation According to the requirements, after the installation of the pipeline, the rubber joint shall be inspected. If they are not qualified, they must be replaced immediately. For example, rubber joints are not allowed to be welded and drilled, otherwise they will cause internal leakage and lead to failure. Fundamentally, quality is the fundamental guarantee of rubber joint production. Installation is simple In the design and installation process, according to the length, installation position, and installation conditions of rubber joints, rubber joints need to be strictly checked after installation is completed. For example, after the installation is completed, it should be checked for leaks, distortion, deformation, holes, etc. When checking, attention should be paid to whether the installation position of the rubber joint is correct, whether the installation size meets the requirements, whether there is contamination and deformation of the rubber expansion joint, etc. Once problems are found, the use should be stopped immediately and the manufacturer should be notified. Rubber joints should be produced and installed by enterprises with relevant qualifications. Only rubber expansion joints that meet the regulations and requirements can be used with confidence.

The rubber expansion joint is generally assembled in the inlet and outlet of the centrifugal pump to isolate the vibration and sound transmission when the centrifugal pump is working, and can have the effect of shock absorption and noise reduction. This equipment is generally assembled at the inlet and outlet of centrifugal pumps to isolate vibration and sound transmission when the centrifugal pumps are working, and can have the efficacy of wear resistance and sound insulation and noise reduction. The inner wall of the commodity is a cylindrical rubber soft joint bracket how to do, the plan is neat and flat, lined with polyester fabric curtain, projecting part of the galvanized steel wire pivot ring, the lining rubber is vulcanized rubber rubber that is resistant to different chemicals, and the surface of the rubber joint is general vulcanized rubber rubber.