Flange stainless steel bellows pressure test is to do what, why must do

The main role in the flange stainless steel bellows is to improve the hardness of the pipe, but the main role of carbon in the stainless steel pipe is to improve the hardness of the pipe, but carbon in stainless steel is also an impurity, the more content the harder at the same time, the greater the chance of the pipe rusting. In the production of flange stainless steel bellows, the need to join the raw material variety is relatively large, which contains a variety of raw materials such as carbon elements and crown elements.

The carbon element as one of the indispensable substances in the flange stainless steel bellows, the level of carbon content directly affects the strength of the material, when the carbon content is relatively high can improve the strength of the pipe, but also to reduce the corrosion. It plays a key role in the wear resistance of the flanged stainless steel bellows. When the element of manganese is higher, the strength of the material gradually increases, and vice versa, the strength of the material begins to decline. In addition, the proportion of the element also directly determines the toughness of the material. Therefore, in the production of flanged stainless steel bellows, the addition and application of various elements must be reasonable.

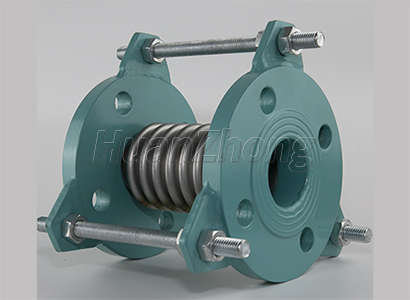

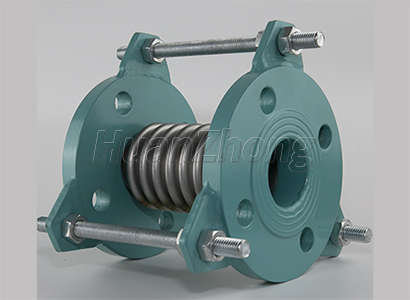

Flange stainless steel corrugated pipe installation and use is mainly the use of the material structure is simple, high hardness, corrosion resistance and other advantages, in order to achieve this application, in the manufacturing process of the pipe, you need to add the right amount of raw materials, such as carbon elements is a very important component of the flange stainless steel corrugated pipe, pipe making by adding carbon elements can increase the hardness and strength of the material, when the carbon element content meets the standard, the pipe use When the carbon content meets the standard, the pipe is not easy to deformation.

Manganese is also one of the important components of flanged stainless steel bellows, and adding manganese to the pipe can enhance the wear resistance of the material, so that it will not be affected by excessive wear during the installation and use of the pipe. As far as the quality of the material is concerned, the proportion of manganese added during processing is also critical. In fact, in the process of making this flanged stainless steel bellows, basic elements such as nickel and aluminum also need to be added, and these basic elements have a very important impact on the quality of the pipe.

After the flanged stainless steel corrugated pipe is processed, it should be removed and moved to a distant place. Without the packaging bag, the surface will be scratched or scuffed, which can affect the appearance of the surface. The packaging itself requires manufacturing costs and the packaging costs require labor costs, the sum of which exceeds the weight of the individual bags.