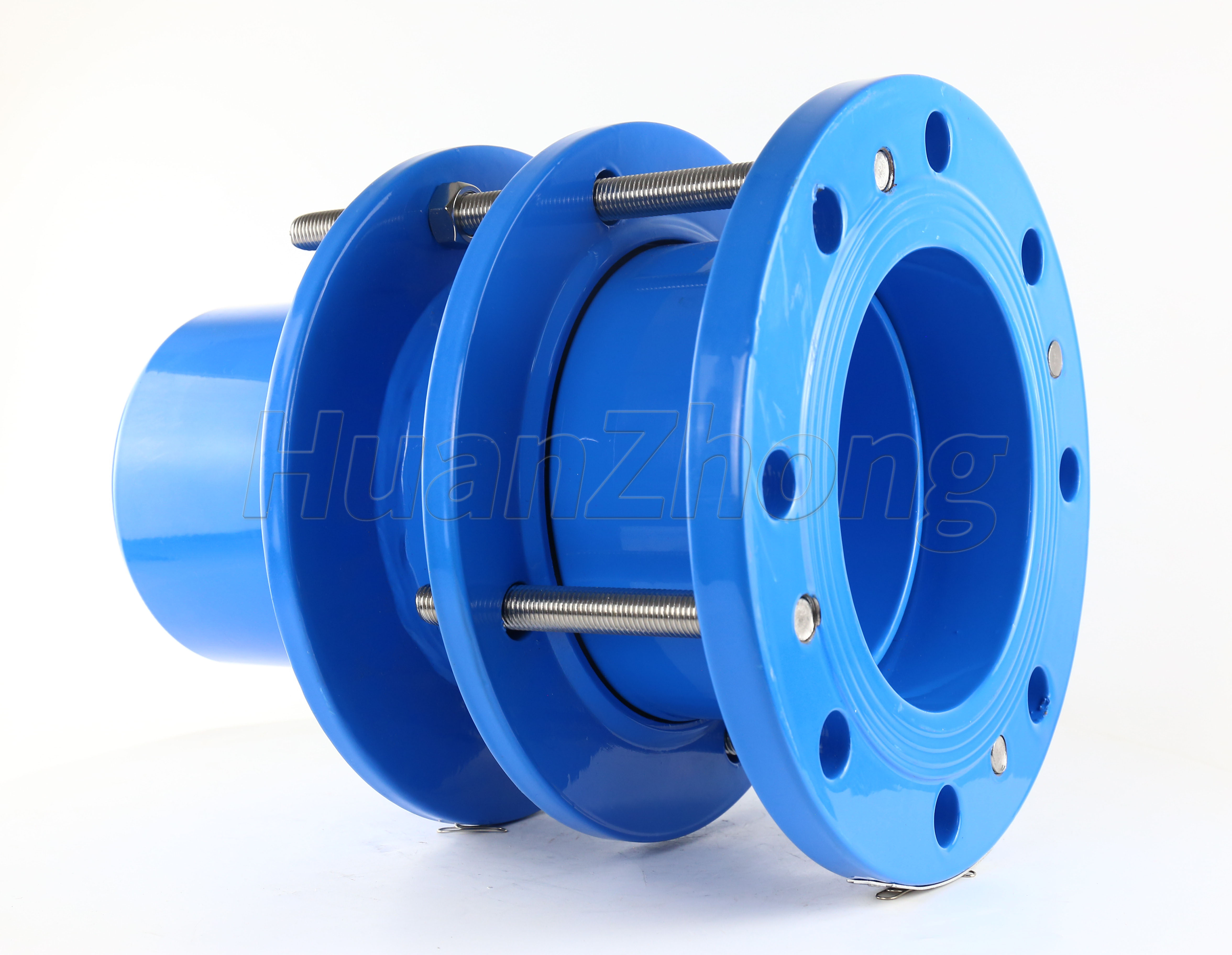

CF type force transfer joints are convenient for pipeline installation and maintenance

The manufacturing process of CF type force transfer joint is to punch a hole in a stainless steel billet at a temperature of 2200°f. Then, under this high temperature, the tool steel becomes soft and spirally formed out of the hole by stamping and drawing. This produces a pipe with an uneven wall thickness and high eccentricity. Therefore, astm allows a larger wall thickness difference for seamless stainless steel pipe than for CF type couplings, which are made from CF type couplings (4-5 feet wide per roll).

These CF joints typically have a large wall thickness difference of 0.002 in. CF joints are cut to a width of πd, where d is the outside diameter of the pipe. CF joints have very small tolerances on wall thickness and at the same time have very uniform wall thicknesses around the entire circumference. There are some differences in the chemical composition of general CF type force transfer joints. The steel composition for the production of seamless stainless steel pipes only meets the basic requirements of astm. In contrast, for the production of CF type force transfer joints the steel contains chemical compositions suitable for welding.

For example, silicon, sulfur, manganese, oxygen and delta ferrite and other elements in a certain proportion of the mixture can be produced in the welding process, an easy to transfer the heat of the weld melt, which makes the entire weld seam weld through. If the lack of the above chemical composition of the steel pipe, such as seamless stainless steel pipe, in the welding process will produce a variety of instability, not easy to weld firmly and weld through. The corrosion resistance of CF-type force transfer joints with the same chemical composition and fully heat-treated CF-type force transfer joints is the same.

In an acidic chloride environment, the corrosion of the welds of incomplete heat-treated CF joints will be more severe, but this is only necessary for corrosion testing, as the environment is not so severe. Thin-walled stainless steel tubes with small thickness/diameter values should be produced by welding; thick-walled tubes with large thickness/diameter values should be made by stamping.