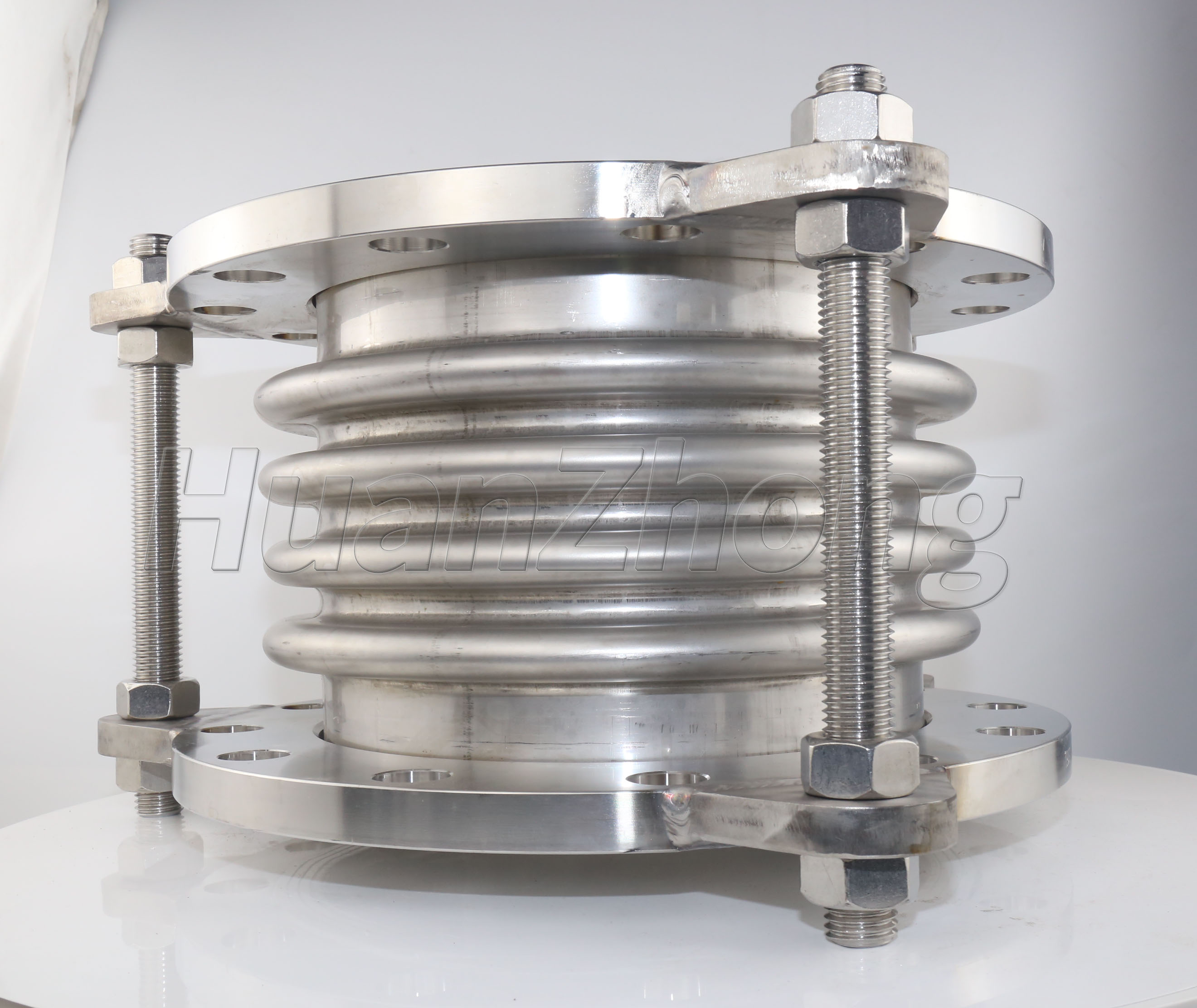

Stainless steel bellows compensator coating process introduction

Stainless steel bellows compensator coating process introduction

The coating process of stainless steel bellows compensator rotates on the outer wall of the stainless steel bellows compensator, so it needs to straighten and straighten the stainless steel bellows compensator, and when moving forward the feeding conduit is rubbed for a long time causing the feeding conduit to have burrs and the stainless steel bellows compensator is linearly scratched. The coating process and the cage are not at the same level, or the straightness is not enough, resulting in linear coating when the stainless steel bellows compensator moves back and forth.

When the paint process, the paint process will enter the paint process, which will cause certain scratches and burrs on the paint process, which will scratch the stainless steel bellows compensator over time. Regularly use infrared laser level to check and calibrate the level of the equipment's and cage, and replace the coating process made of iron with the coating process made of stainless steel to reduce the linear scratches caused by the coating process.

When replacing, chamfer and deburr the paint process of and periodically repair the in-use ones with fine sandpaper. Reduce the friction of the coating process to the coating process, reduce the burr of the coating process, thus reducing the scratch of the stainless steel bellows compensator caused by the coating process problem. When we operate the stainless steel bellows compensator, we must follow the operating specifications and meet certain requirements.

Overload or misoperation can cause damage to the stainless steel bellows compensator, so be sure to avoid these risks. We need to add lubrication to the forming process of the stainless steel bellows compensator. Cleaning is also not very convenient. The bending characteristics of the coating process itself and surface corrosion may also endanger the bending quality. In the field engineering construction, operators also master the production and processing of the raw materials of the pipe, distinguishing the production and processing characteristics and surface corrosion.