What is an expansion joint

What is an expansion joint

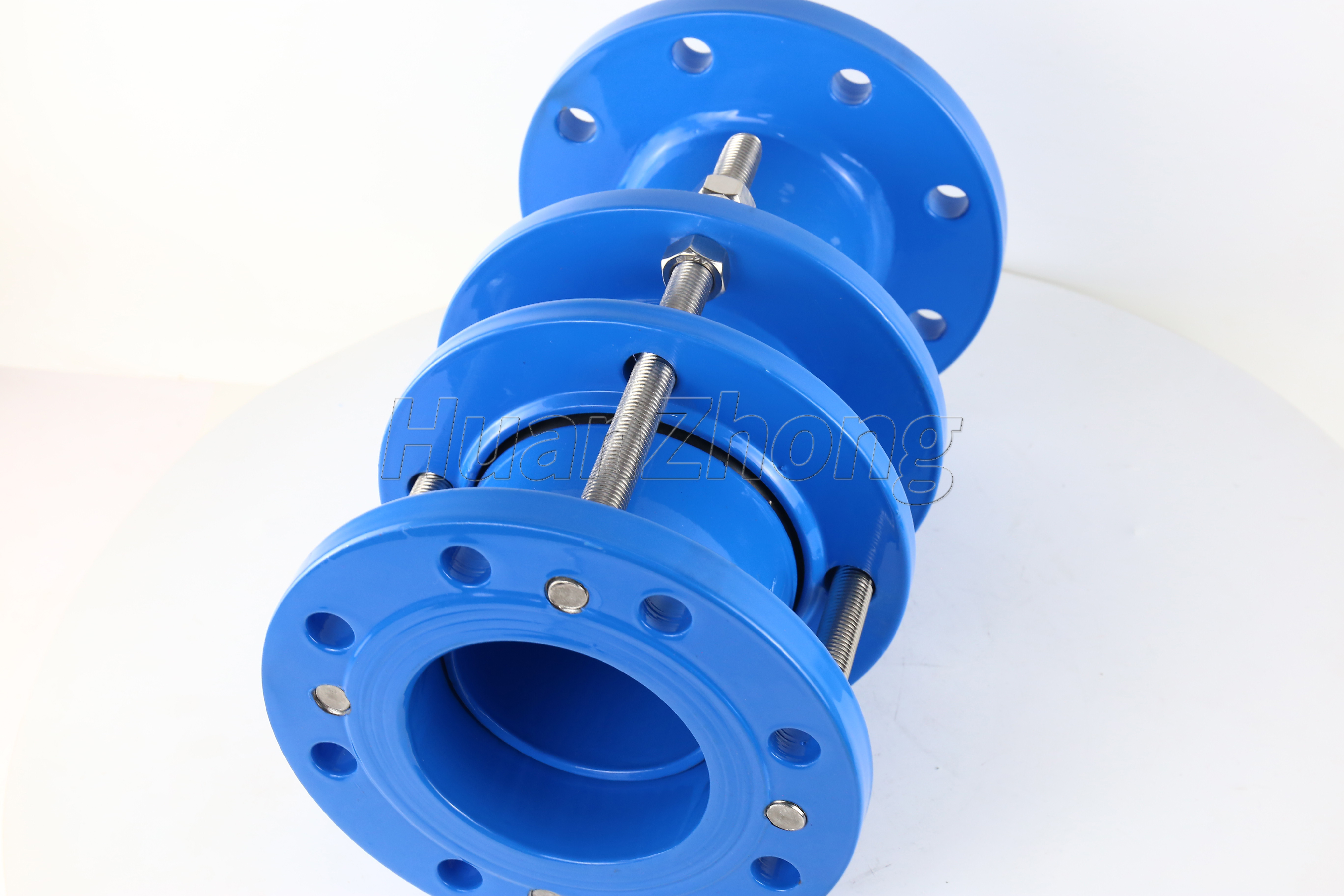

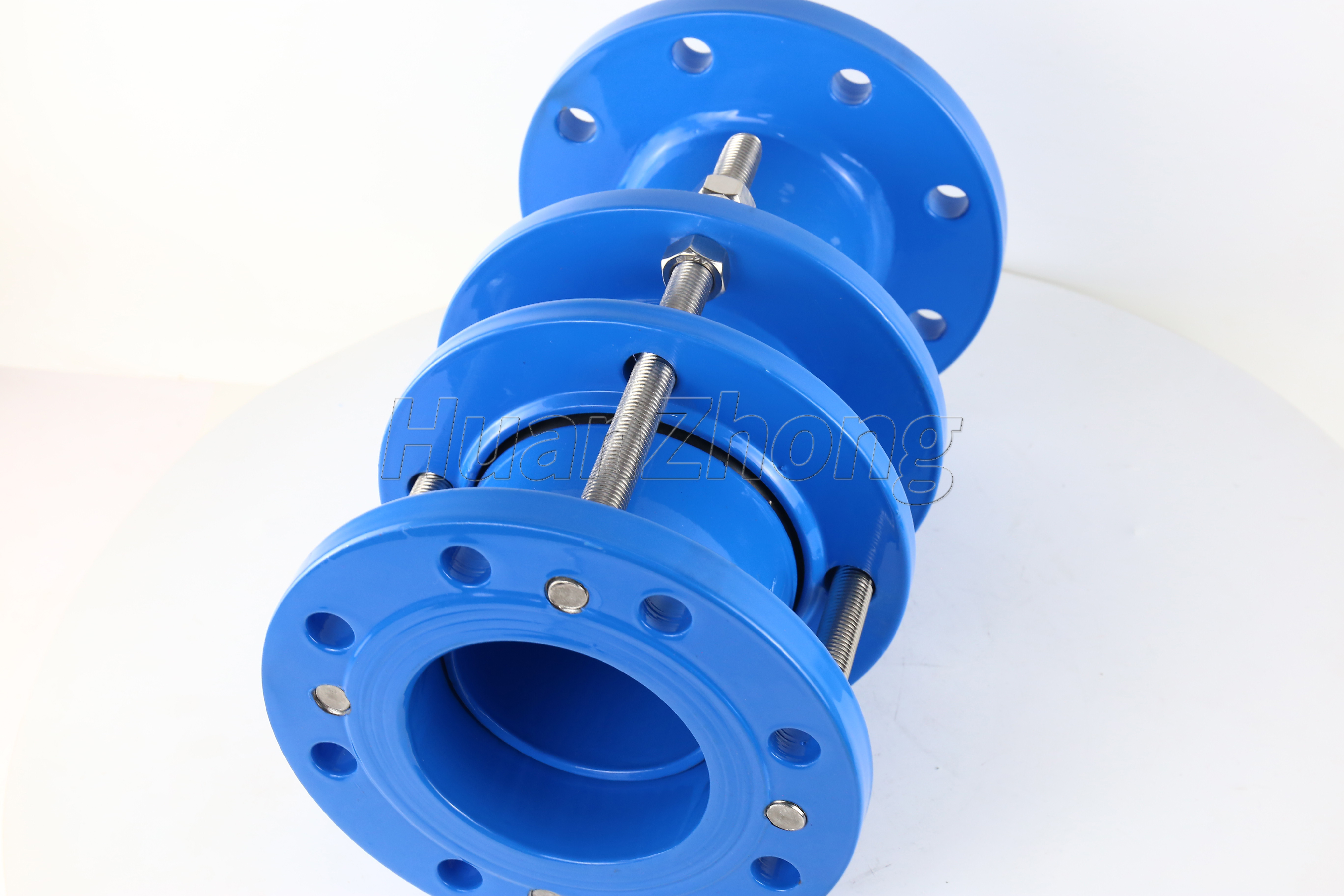

Expansion joint is composed of loose-fitting expansion joint and short pipe flange, transmission screw and other components, which can transfer the pressure thrust of the connected parts and compensate the pipeline error, but cannot absorb the axial displacement. It is used for the loose-fitting connection of pumps, valves, pipelines and other accessories. After installation and welding, the gland bolts are evenly tightened diagonally in order to make it become a whole and have a certain displacement, which can transmit the axial thrust to the whole pipeline when working. The transfer expansion joint connection is to connect two pipes, fittings or equipment, each fixed on a flange first, between the two flanges, plus the flange gasket, fastened together with bolts, completed the connection. Force expansion joint is divided into threaded connection flange and welding flange. There are threaded connection flanges for small diameters of low pressure, and welded flanges are used for large diameters of high pressure and low pressure. The thickness of flanges and the diameter and number of connection bolts are different for different pressures.

Expansion joint as a compensation pipeline fittings, the same pipeline installation in the high rise should be guaranteed, the design must be reasonable vertical partitioning of the water supply system and hot water system and add pressure reducing equipment, construction to ensure the quality of the pipeline welding and firm fixed to ensure the normal operation of the system. In the high level, the same consideration of noise prevention and vibration prevention must be carried out reasonably to ensure the solid and reasonable installation of the pipes, and some necessary measures such as vibration isolation must be taken. There are manual rust removal, mechanical rust removal and pickling rust removal for pipelines. Manual descaling is carried out with wire brush or sand cloth. Mechanical descaling is carried out with electric descaling machines, various electric descaling tools or sandblasting method.

Steel pipe pickling and rust removal is generally carried out with sulfuric acid or hydrochloric acid. The concentration of sulfuric acid is generally 10 to 15, and the soaking time is at room temperature. If the acid is heated to a certain degree of heat, the rust removal is significantly accelerated. When preparing sulfuric acid solution, sulfuric acid should be poured into water slowly, and it is strictly forbidden to pour water into sulfuric acid. The concentration of hydrochloric acid is generally 10 to 15, and the pickling is soaked at room temperature for the specified time. After pickling, it should be washed with water and neutralized with sodium carbonate solution with a concentration of 50, then rinsed with hot water 2 to 3 times and dried. Expansion joints can be used in a variety of harsh work situations. However, due to the influence of the environment, the life of expansion joints can be indirectly shortened if they are used in outdoor applications for a long time or if maintenance is not in place. In the early stage of design and manufacturing, expansion joints focus on the adaptability of the product to the environment, so they are coated with anticorrosive coating, which can effectively guarantee the adaptability of the product to the environment in the process of application.