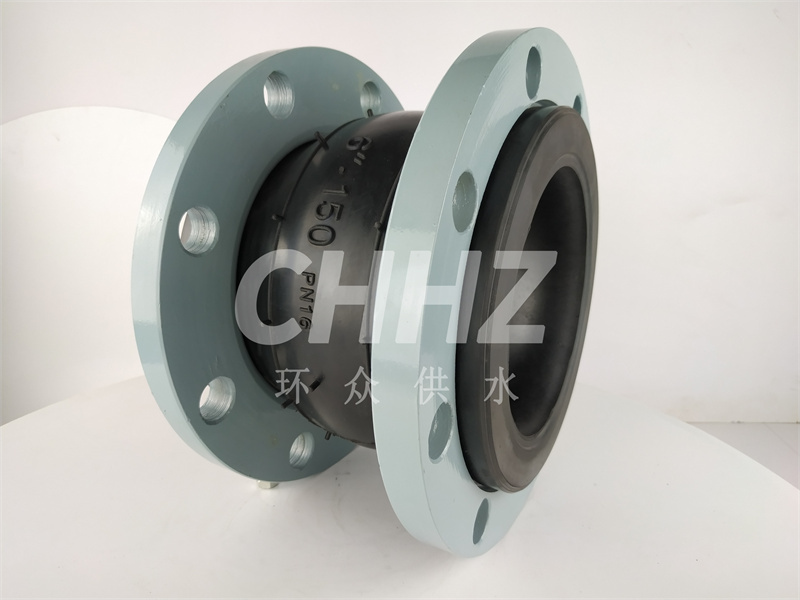

Huanzhong rubber soft connection is more stable

huanzhong rubber soft connection is more stable

Rubber soft connection can play a good sealing role, compared with some mechanical seals, it is more flexible, in the process of installation we should pay attention to some details of the problem, so that after installation, can bring a stronger sealing effect. Let's take a closer look at the following installation details of rubber joints.

Most rubber joints are installed in the internal structure of the pipeline, which not only provides a small repair to the inclination of the pipeline, but also plays a role in vibration and noise reduction of the pipeline, which is a very practical pipeline connection. When mostly due to non-compliant installation and use, causing problems with the pipeline, it boils down to the rubber joint problem, summarizing several types of situations that can occur due to non-compliance with rubber joint installation, as detailed below: When installing rubber joints, tightening the screws is a process that must be paid attention to, and the diagonal tightening approach cannot be transformed, otherwise there will be a partial seal that is not tight, which leads to water seepage in the rubber joint. .

Rubber soft joint pulling: this situation is due to the installation of the specific pipeline Lashin situation exceeds the limit of the rubber joint stretching length, resulting in the flange from both sides of the ball directly pulled off, in this case, please regularly replace the double spherical rubber joint to use, or can also be used in the rubber joint limit device, limit device not only for the rubber joint Lashin has a certain standard, for The limit device not only has a certain standard for the rubber joint, but also has a really big improvement for the jitter of the pipe.

Rubber soft joints occurring infiltration variation: this happens to the general rubber joints installed in the oil pipeline pipeline, because the raw material oil plastic has corrosive, long time infiltration will make the rubber joints occur edema problems, may lead to sealing problems and the reduction of their own product quality problems, so in the oil pipeline pipeline must be used acid and alkali resistant rubber joints. Rubber soft joint specification variation: The variation of the specification is from the level of the pipeline's cumulative grade distortion. Due to the large inclination of some pipes, deformation will occur during transportation. Rubber joints are a kind of goods with particularly high compressive strength, but they are helpless to deformation. In this case, rubber joints are replaced by high pressure resistant rubber joints.