Wire fastening|Clamp connection type rubber joint specification requirements

Wire fastening|Clamp connection type rubber joint specification requirements

In practice, we found that it is very difficult to meet the design and construction specification requirements for large size pipelines such as DN80 or above. In actual construction for DNl50 and other pipelines, often the flange is installed, and then the number is made up and sent to the galvanizing plant galvanized, galvanized and then assembled, although this method meets the anti-corrosion requirements, but undoubtedly also increased the cost of production, but also extended the construction period. Because of construction difficulties, construction units sometimes directly use the method of connection, this operation is not standardized, and is also not allowed, we introduced this new process of galvanized steel pipe clamp connection, then overcome these shortcomings.

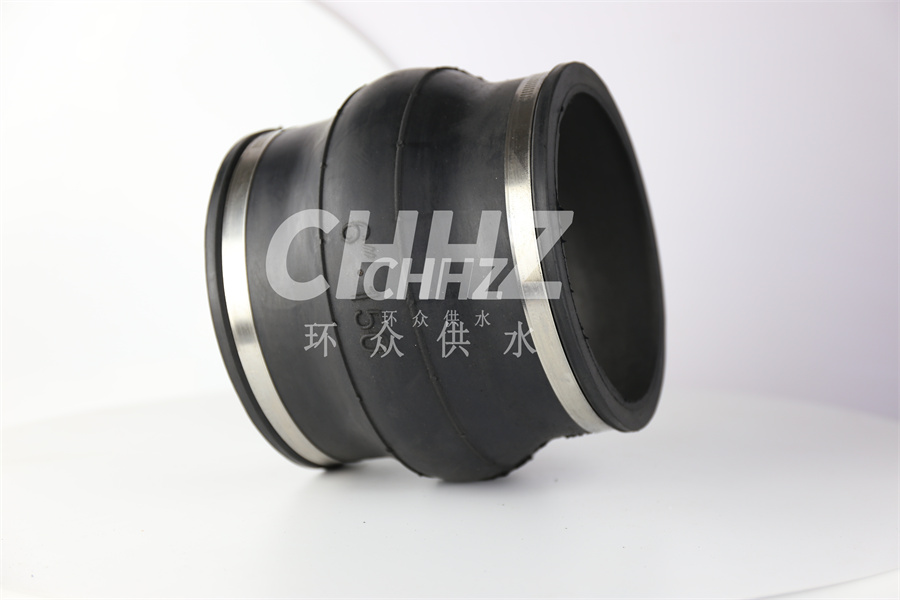

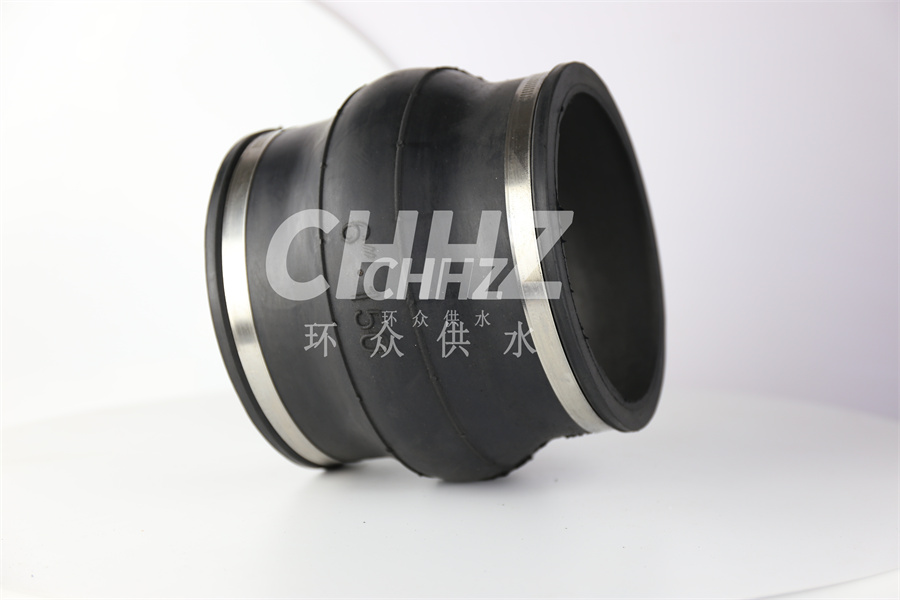

The fillet soft joint is a kind of high elasticity, high airtightness, medium resistance and weather resistance pipeline joint. The fillet rubber soft joint utilizes the advantages of rubber's elasticity, high airtightness, medium resistance weather resistance and radiation resistance, etc. It is made of degree, cold and heat stable polyester cord fabric beveled and compounded after high pressure and high temperature mold vulcanization. It is made of high pressure steel wire braid or winding hose and steel fittings by special equipment buckling, used to connect all kinds of hydraulic components in the hydraulic system, rubber joints or a circle of sealing surface inside the pair of clamping butterfly valve simply does not have an effective contact surface, the pressure is larger when it simply can not be sealed, so it is simply not possible. Rubber joints have small volume, light weight, good elasticity, easy installation and maintenance, and can absorb lateral, axial and angular displacements generated by pipeline vibrations after installation; not subject to pipeline uncentered, flanges not parallel, can reduce the noise generated by vibrations such as pipeline pumps after installation, strong vibration absorption capacity, inside seamless high pressure rubber joints, in high temperature resistant, acid and alkali resistant, oil resistant pipelines more effectively prevent corrosive media to rubber The seamless high-pressure rubber joints are mainly used for hydraulic power transmission or transmission of water, gas, oil and other high-pressure media under the condition of working temperature from -40℃ to +100℃, in order to ensure the circulation of liquid and transfer of liquid energy.

So as to achieve the purpose of compensating the pipeline due to thermal expansion and contraction, the displacement produced by water transmission. In addition to the same characteristics of high strength, low noise, good fireproof performance, long service life, good bendability and seismic performance of its connection, the clamp joint type rubber joint connection also has the characteristics of synchronous construction, high pipe utilization, easy pipeline clearance, reduced the number of hydraulic tests and shortened construction period to improve economic efficiency. In addition, this kind of interface of clamp-connected rubber joint is fastened with bolts on the outside, which avoids the defects that the flange of the flexible interface of the socket is easy to touch and the bolts against the foot of the wall are difficult to fix, and has the advantages of easy operation and so on. Flexible rubber joints in the development of the evolution and innovation have made a breakthrough in the face, in review of the flexural rubber joints over the years, the development of flexural rubber joints is now standing at a higher peak, from the international market and domestic market demand can be seen, the world has a large demand for flexural rubber joints. Flexible rubber joints have made a breakthrough in the evolution and innovation of development. In reviewing the development of flexural rubber joints over the years, the development of flexural rubber joints is now standing at a higher peak, as seen from the international market and domestic market demand, the world has a large demand for flexural rubber joints.