Corrugated compensator measures to prevent water strikes

Corrugated compensator measures to prevent water strikes

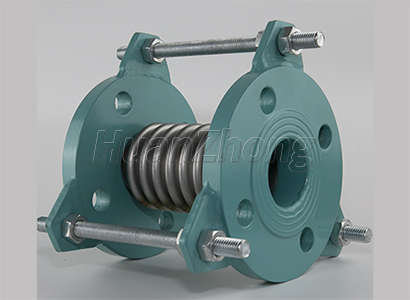

Corrugated compensator is a common mechanical device used to compensate for heat, pressure and other movements in the pipeline to ensure the stability and reliability of the pipeline system. However, in the process of using corrugated compensator, it also faces some problems, such as waterproof strike.

Corrugated compensator measures to prevent water strikes mainly include the following aspects:

1. material selection: when choosing materials, you need to take into account the strength and wear resistance of the material. At present, the corrugated compensator materials commonly used in the market include stainless steel, copper, aluminum, etc.. Among them, stainless steel materials have high strength and endurance, suitable for high temperature and high pressure environment; copper and aluminum materials have good electrical and thermal conductivity, which can enhance the sealing performance of the corrugated compensator.

2. Structure design: The structure design needs to be optimized according to the use environment. For example, in high temperature and high pressure environment, it is necessary to use sealing structure to increase the sealing performance; in low temperature and low pressure environment, it is possible to use open structure to reduce the sealing performance requirements.

3. Process: The processing of the corrugated compensator needs to use a special process to ensure that it has good weldability and sealing performance. During the processing, the surface of the corrugated compensator needs to be coated to improve its waterproof performance. In the welding and assembly process, it is also necessary to add waterproofing agents and anti-corrosion agents, etc., to ensure its long-term stability.

4. use maintenance: corrugated compensator in use needs to be regularly maintained and inspected to ensure that it works properly and avoid damage. For northern areas, waterproof measures are needed to avoid damage due to harsh climate.

The corrugated compensator is an integral part of the piping system, and special attention needs to be paid to the above-mentioned waterproof striking problems when in use. Choosing suitable materials and structural design, as well as carrying out regular maintenance and inspection, are the keys to ensure the long-term stable operation of the corrugated compensator.