Introduction, characteristic performance of pipe gland expansion joint.

Introduction, characteristic performance of pipe gland expansion joint.Pipe gland expansion joints are essential components in piping systems, designed to compensate for thermal expansion, reduce vibrations, and absorb movements that occur due to changes in temperature and pressure. These joints offer numerous characteristic performances that make them an ideal choice for a wide range of applications in various industries. In this article, we will explore the introduction and the key performance characteristics of pipe gland expansion joints.

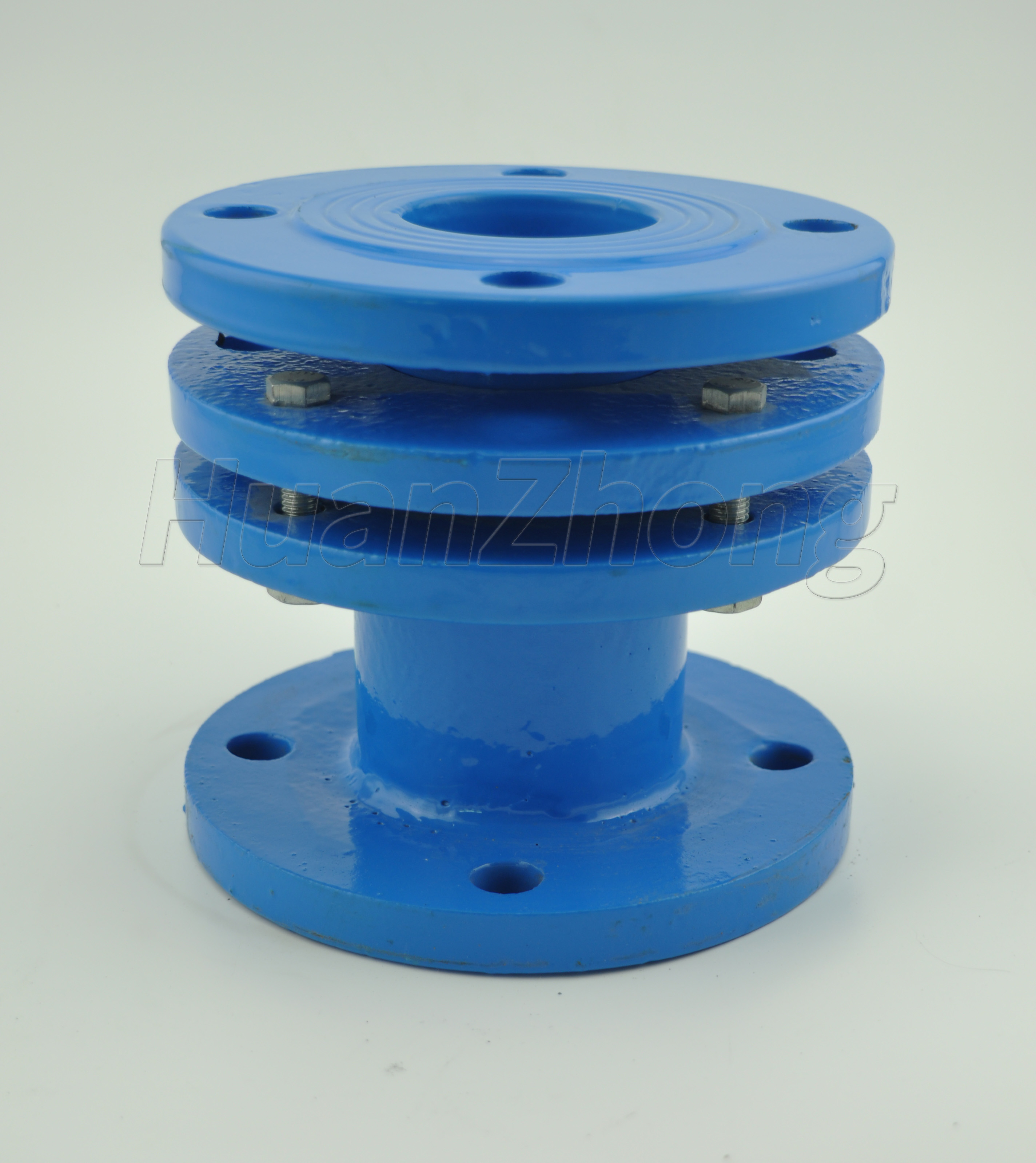

Introduction: Pipe gland expansion joints, also known as pipe compensators or pipe expansion compensators, are flexible connectors installed in piping systems to accommodate thermal expansion and contraction. They are typically made of rubber, fabric, or metal materials, depending on the specific requirements of the system. These expansion joints play a vital role in preventing damage to the system by absorbing vibrations and movements that occur due to thermal expansion, thereby extending the life of the piping and equipment.

Characteristic Performance:

1 . Flexibility: Pipe gland expansion joints are highly flexible, allowing them to accommodate axial, lateral, and angular movements in piping systems. They can compensate for thermal expansion and contraction, as well as absorb vibrations and shocks caused by the flow of fluids or external forces. The flexibility of these joints ensures that they can adapt to the changing conditions within the system without exerting excessive stress on the pipes.

2 . Noise and Vibration Reduction: One of the significant advantages of pipe gland expansion joints is their ability to reduce noise and vibration in piping systems. The flexible design of these joints absorbs and disperses vibrations, preventing them from transmitting to other parts of the system or surrounding structures. This feature helps to mitigate noise levels and protect the integrity of the system, reducing the potential for equipment damage or failure.

3 . Compensation for Thermal Expansion: Pipe gland expansion joints effectively compensate for the thermal expansion and contraction of pipes in heating, ventilation, air conditioning (HVAC), and other high-temperature systems. As the temperature changes, the joints expand or contract accordingly, ensuring that the stress on the pipes and connected equipment is minimized. This compensation prevents the potential for leaks, cracks, or pipe damage due to thermal stress.

4 . Pressure Resistance: Pipe gland expansion joints are designed to withstand various pressure conditions within the system. The materials used in their construction are selected based on the required pressure rating, fluid compatibility, and operating conditions. The joints effectively seal the system and maintain the required pressure levels, thereby ensuring the efficient transfer of fluids without any leakage or pressure loss.

5 . Longevity and Durability: Pipe gland expansion joints are built to withstand harsh operating conditions, high temperatures, and aggressive chemical environments. The materials used in their construction are selected for their resistance to corrosion, abrasion, and degradation. This ensures their longevity and durability, reducing the need for frequent maintenance or replacement.

6 . Easy Installation and Maintenance: Pipe gland expansion joints are relatively easy to install and maintain. They can be easily connected to the existing piping system using standard flange connections or other suitable methods. Routine inspections and maintenance activities, such as visual inspections, cleaning, and lubrication, ensure their optimal performance and prolong their lifespan.

In conclusion, pipe gland expansion joints are essential components in piping systems, offering characteristic performances such as flexibility, noise and vibration reduction, compensation for thermal expansion, pressure resistance, longevity, and easy installation and maintenance. These features make them a reliable choice for various applications, safeguarding the integrity of piping systems and prolonging the life of equipment.