The principle of using metal pipe expanders.

The principle of using metal pipe expanders.

Metal pipe expanders are widely used in various industries, including manufacturing, construction, and maintenance, to increase the diameter and overall size of metal pipes. The principle behind the operation of metal pipe expanders is based on mechanical force and deformation. In this article, we will explore the principle of using metal pipe expanders in more detail.

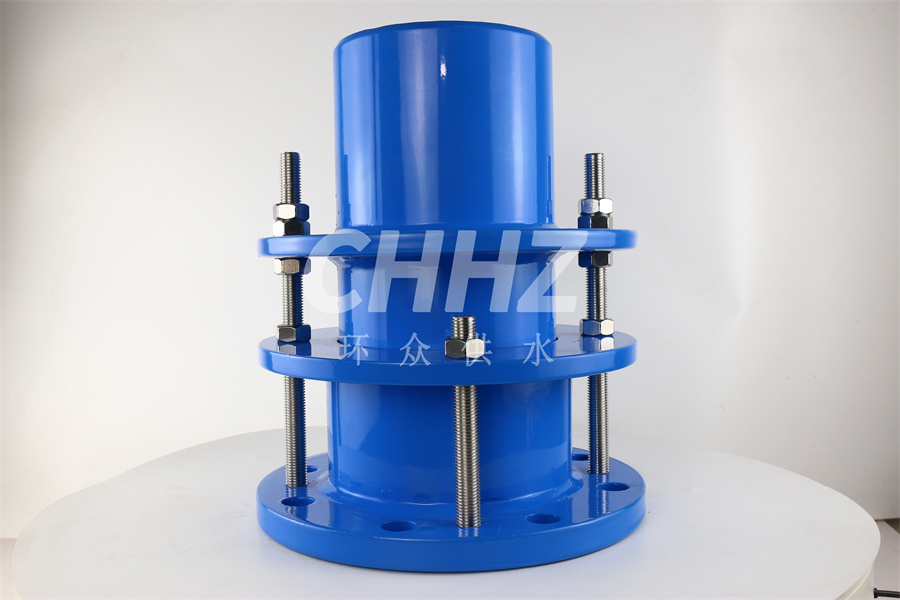

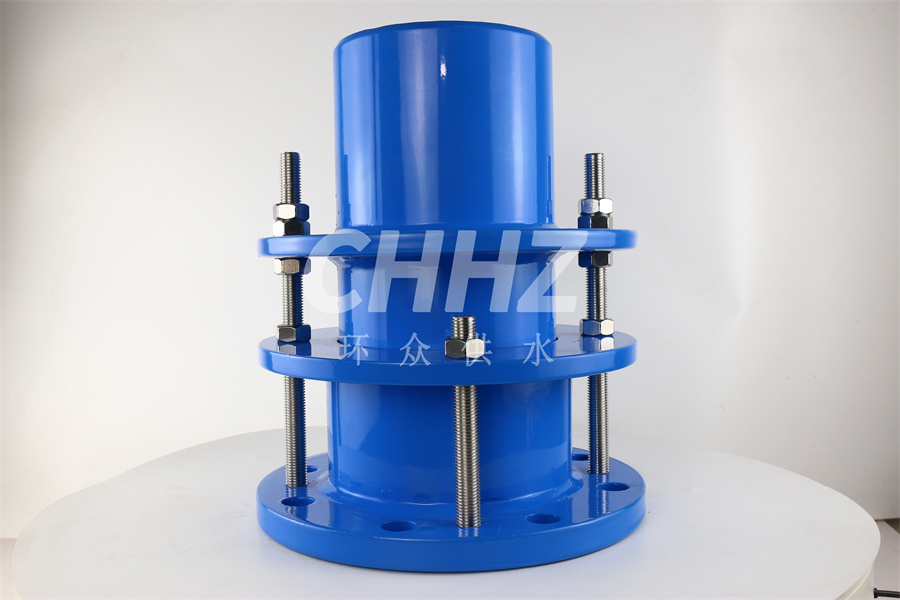

1 . Introduction to Metal Pipe Expanders:

Metal pipe expanders are mechanical tools that are designed to expand the diameter of metal pipes. They are commonly used in applications where there is a need to join two pipes with different diameters or to repair damaged pipes. The basic design of a metal pipe expander consists of a set of expanding heads that are inserted into the pipe and expanded using hydraulic pressure or manual force.

2 . Expansion Process:

The expansion process of metal pipe expanders involves applying controlled force to the expanding heads, which causes the metal pipe to stretch and increase in diameter. The expanding heads are inserted into the pipe through one end, and as force is applied, they expand radially. This radial expansion exerts pressure on the inner walls of the pipe, causing it to deform and increase in size.

3 . Hydraulic Pressure vs. Manual Force:

Metal pipe expanders can be operated using hydraulic pressure or manual force, depending on the size and type of pipe being expanded. Hydraulic pipe expanders utilize hydraulic power to generate the necessary force for expansion. A hydraulic pump is used to pressurize hydraulic fluid, which then applies force to the expanding heads, causing them to expand and stretch the pipe. Manual pipe expanders, on the other hand, require the operator to exert force manually using a lever or handle. These types of expanders are typically used for smaller pipes or in situations where hydraulic power is not readily available.

4 . Temperature Control:

In certain applications, such as expanding pipes in high-temperature environments, temperature control becomes crucial. When expanding pipes at high temperatures, thermal expansion of the metal must be taken into account. The metal pipe expander must be designed to accommodate the thermal expansion of the pipe and ensure that the expansion process is carried out accurately.

5 . Applications:

Metal pipe expanders find wide applications in various industries. They are commonly used in the manufacturing of heat exchangers, boilers, and other equipment that require precise connections between different pipe diameters. They are also used in the construction industry for joining pipes and repairing damaged sections of pipelines. Metal pipe expanders have significant applications in industries such as oil and gas, petrochemicals, power generation, and HVAC (heating, ventilation, and air conditioning).

In summary, metal pipe expanders operate on the principle of applying mechanical force and deformation to increase the diameter of metal pipes. The expanding heads of the expander stretch the pipe by exerting radial pressure on its inner walls. Whether operated through hydraulic pressure or manual force, these tools find extensive applications in various industries where precise and secure connections between different pipe diameters are required. By understanding the principle behind metal pipe expanders, manufacturers and technicians can utilize this equipment effectively in their operations and ensure the efficient functioning of their piping systems.