What does a stainless steel double flange limit expansion joint do?

What does a stainless steel double flange limit expansion joint do?

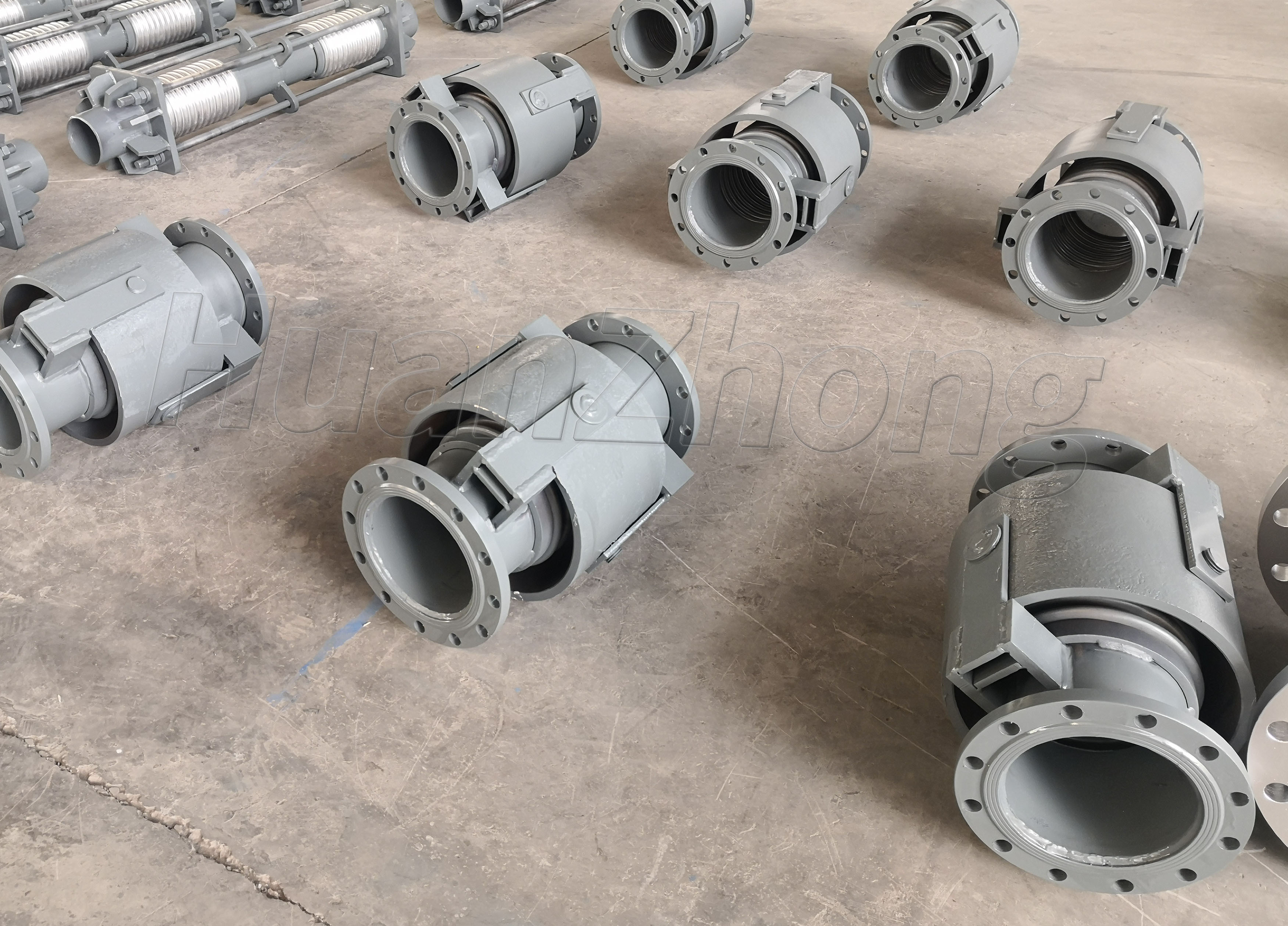

A stainless steel double flange limit expansion joint is a crucial component used in piping systems to absorb thermal expansion and contraction, as well as to accommodate mechanical movements and vibrations. It acts as a flexible connection between two pipes or equipment, allowing for lateral, axial, and angular movement while maintaining a leak-free and reliable seal. In this section, we will explore the functions and benefits of a stainless steel double flange limit expansion joint in more detail.

1 . Absorption of Thermal Expansion and Contraction: One primary function of a stainless steel double flange limit expansion joint is to absorb thermal expansion and contraction in piping systems. When a pipeline is subjected to temperature variations, the pipes expand and contract. Without a flexible joint, this thermal movement can lead to excessive stress on the pipes and other components, resulting in leaks, cracks, or failure. The expansion joint allows the connected pipes to expand and contract freely, reducing the strain on the system and ensuring its integrity.

2 . Compensation for Misalignments: A double flange limit expansion joint is capable of compensating for minor misalignment between two connected pipes or equipment. It can accommodate angular, lateral, and axial misalignments caused by various factors such as installation errors, ground settlement, or equipment movement. By absorbing these misalignments, the expansion joint minimizes stress concentration in the system, preventing damage and ensuring a tight seal.

3 . Reduction of Mechanical Vibrations: Vibrations are a common occurrence in piping systems due to fluid flow, equipment operation, or environmental factors. Excessive vibrations can lead to fatigue, which can result in premature failure of the pipes or equipment. A stainless steel double flange limit expansion joint acts as a dampener, absorbing and dissipating mechanical vibrations. By reducing the transmission of vibrations, it protects the system from damage and extends its service life.

4 . Leakage Prevention: The double flange design of this expansion joint ensures a robust and reliable connection between the pipes or equipment. It provides a secure seal, preventing leaks and maintaining the integrity of the system. The flange connection also allows for easy installation and maintenance, enabling quick disassembly and reassembly when required.

5 . Corrosion Resistance: Stainless steel is widely used in the construction of expansion joints due to its excellent corrosion resistance properties. It can withstand harsh environments, sustained exposure to chemicals, moisture, or extreme temperatures, without deteriorating or compromising its performance. This ensures the longevity and reliability of the double flange limit expansion joint, even in demanding operating conditions.

6 . Easy Installation and Maintenance: Stainless steel double flange limit expansion joints are relatively easy to install. The flanges can be bolted directly to the pipes or equipment, providing a secure and leak-free connection. Additionally, routine maintenance tasks such as inspection, cleaning, or gasket replacement can be performed efficiently due to the accessible design of the expansion joint. This helps minimize downtime and reduce maintenance costs.

In conclusion, a stainless steel double flange limit expansion joint plays a vital role in ensuring the proper functioning and longevity of piping systems. It absorbs thermal expansion, compensates for misalignments, reduces mechanical vibrations, prevents leaks, and offers corrosion resistance. Its installation and maintenance are relatively simple, making it an essential component for a wide range of industries where piping systems are used.