Axial internal pressure type corrugated compensator application characteristics and selection method

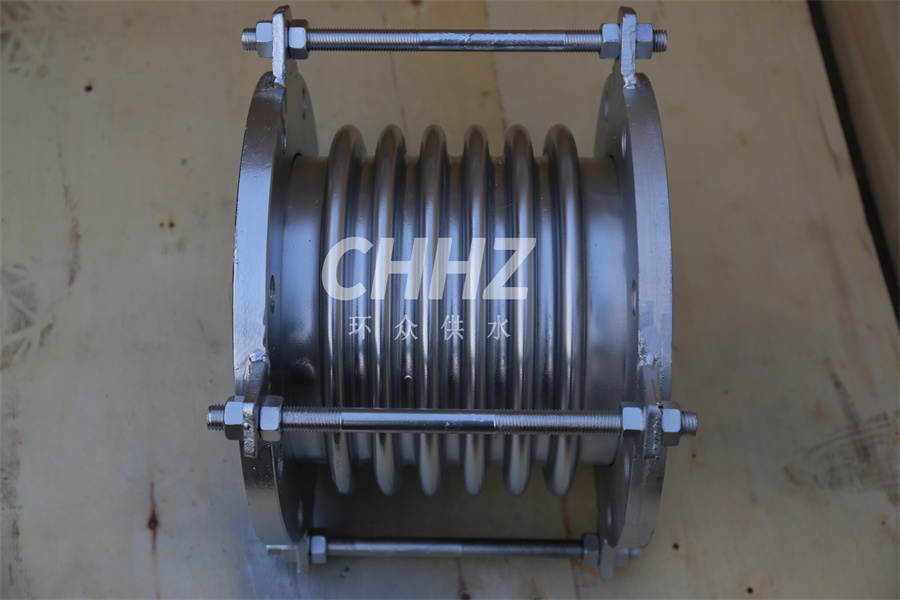

Axial internal pressure type corrugated compensator application characteristics and selection method. Axial internal pressure type corrugated compensators are widely used in various industries to accommodate axial movement, absorb vibrations, and compensate for thermal expansion and contraction in piping systems. In this article, we will discuss the application characteristics and selection method of axial internal pressure type corrugated compensators.

Firstly, let's understand the application characteristics of axial internal pressure type corrugated compensators. These compensators are specifically designed to handle axial movements in piping systems. Axial movements occur when there is a change in the length of the pipeline due to factors such as temperature changes, vibration, or mechanical loads. Axial compensators are ideal for applications where there is a need to accommodate large axial movements.

One of the main advantages of axial internal pressure type corrugated compensators is their ability to handle high-pressure applications. They are designed to withstand and compensate for the internal pressure generated by the fluid flowing through the pipeline. These compensators provide a flexible and reliable solution for high-pressure systems, ensuring the integrity and safety of the piping system.

Another characteristic of axial internal pressure type corrugated compensators is their ability to absorb vibrations. Vibrations can occur due to the flow of fluid, mechanical equipment, or external factors. These compensators are designed to dampen and minimize the transmission of vibrations, reducing the stress on the piping system and preventing potential damage or fatigue failure.

Now, let's discuss the selection method for axial internal pressure type corrugated compensators. When selecting a compensator, it is important to consider various factors to ensure the optimal performance of the system.

Firstly, the design and material selection of the compensator should be based on the specific requirements of the application. Factors such as operating temperature, pressure, and the nature of the fluid being transported should be taken into consideration. It is crucial to select a compensator that can withstand the anticipated operating conditions without compromising its performance.

Additionally, the size and dimensions of the compensator should be carefully chosen. This includes considering the diameter and length of the compensator to ensure proper accommodation of the anticipated axial movements. It is important to select a compensator that has the appropriate flexibility and displacement capacity to accommodate the axial movements without overstraining the system.

Furthermore, the installation and maintenance requirements should be considered during the selection process. It is important to choose a compensator that is easy to install and maintain, allowing for efficient and cost-effective operation of the piping system.

In conclusion, axial internal pressure type corrugated compensators are versatile and reliable solutions for handling axial movements, absorbing vibrations, and compensating for thermal expansion and contraction in piping systems. When selecting these compensators, it is essential to consider factors such as operating conditions, design and material selection, size and dimensions, and installation and maintenance requirements. By following a proper selection method, the optimal compensator can be chosen to ensure the efficient and safe operation of the piping system.