What is the difference between painting and spraying the surface of a cased corrugated compensator?

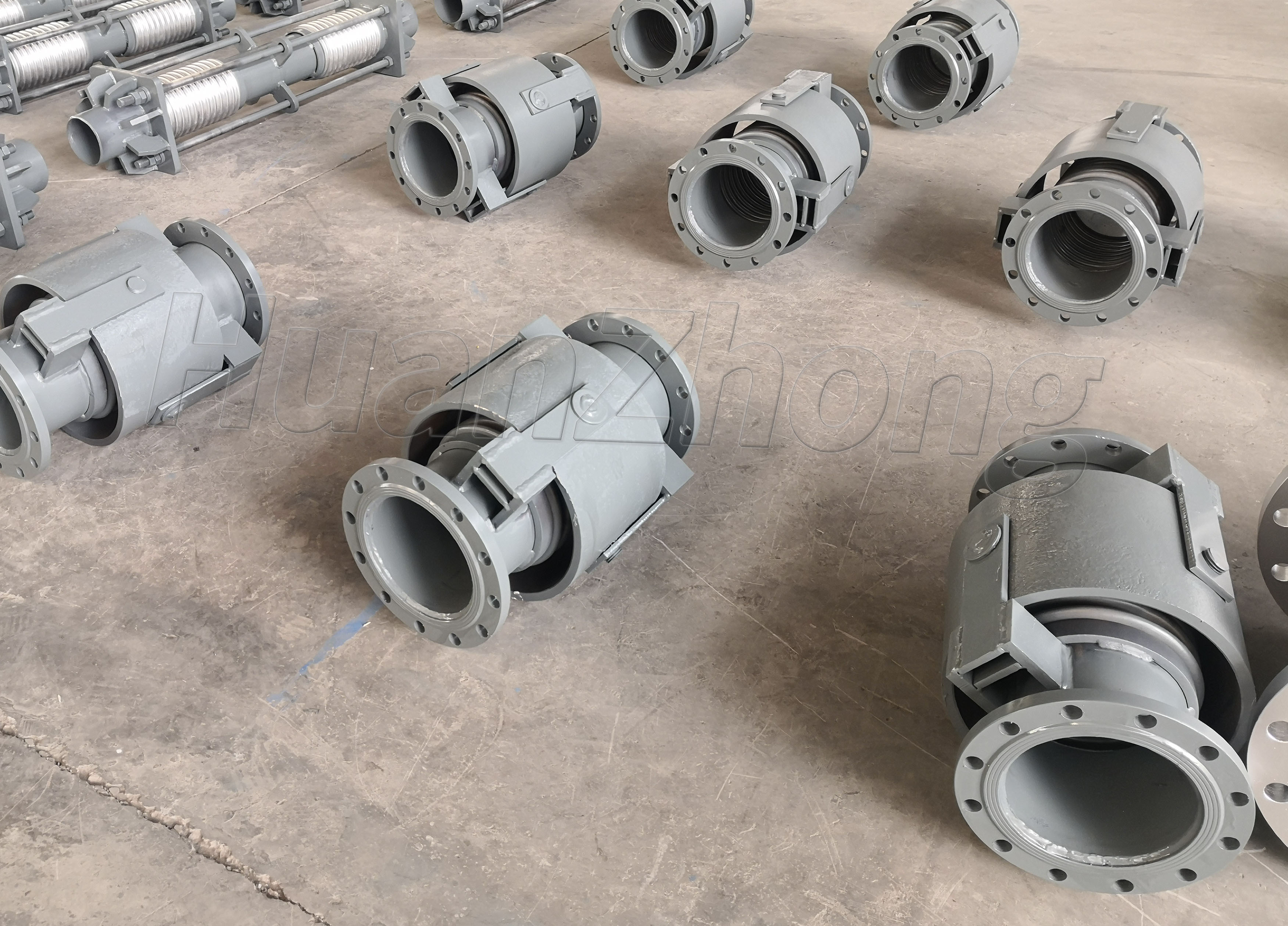

What is the difference between painting and spraying the surface of a cased corrugated compensator? The surface treatment of a cased corrugated compensator is an essential step in enhancing its durability, aesthetics, and performance. Two common methods for surface treatment are painting and spraying. In this essay, we will discuss the difference between painting and spraying the surface of a cased corrugated compensator, including the process, benefits, and considerations involved in each method.

Painting is a surface treatment method that involves applying a liquid paint coating to the surface of the compensator. The process typically involves several steps, including surface preparation, primer application, paint application, and curing. Surface preparation may involve cleaning, degreasing, and sanding the surface to ensure proper adhesion of the paint.

Spraying, on the other hand, refers to the application of a liquid coating using a spray gun or similar equipment. This method allows for a more uniform and controlled application of the coating. The spraying process involves atomizing the liquid coating into small droplets and directing them towards the compensator's surface. The sprayed coating then adheres to the surface, forming a protective layer.

There are several differences between painting and spraying in terms of the process, benefits, and considerations:

Application Process: Painting involves manually applying paint using brushes, rollers, or other applicators. It allows for more precise control over the paint thickness and can be suitable for smaller areas or intricate designs. On the other hand, spraying offers faster coverage and is more efficient for large or complex surfaces. It provides a uniform and seamless finish, especially for curved or irregularly shaped compensators.

Coating Thickness: Painting allows for thicker layers of coating, which can offer enhanced protection against corrosion, UV radiation, or other environmental factors. Spraying, on the other hand, typically provides thinner coatings, which may be more suitable for achieving a specific aesthetic appearance or ensuring flexibility in compensator movements.

Coating Uniformity: Spraying offers better control over the coating's uniformity and can result in a more even distribution of the paint or protective coating. This is especially important for large compensators or surfaces with complex shapes, where manual painting may result in uneven coverage or missed areas.

Efficiency: Spraying is generally a more efficient method in terms of time and labor. It allows for faster application and drying times, reducing the overall production or installation time. Painting, on the other hand, may require longer drying times between coats and may need multiple layers to achieve the desired thickness.

Material Compatibility: When considering the choice between painting and spraying, it is essential to consider the compatibility of the coating material with the compensator's surface and the specific operating conditions. Some coatings may be more suitable for painting, while others may work better with spraying. Compatibility with the compensator's material, temperature range, and exposure to chemicals or UV radiation should be considered.

In conclusion, painting and spraying are two common methods for surface treatment of cased corrugated compensators. While painting allows for thicker coatings and precise application, spraying offers better uniformity, efficiency, and coverage for larger or complex surfaces. The choice between painting and spraying depends on several factors, including the desired coating thickness, aesthetics, efficiency, and material compatibility. Proper surface preparation and selecting the appropriate coating material are essential considerations for ensuring the longevity and performance of the compensator.