Working Pressure of Steel Transmission Expansion Joint.

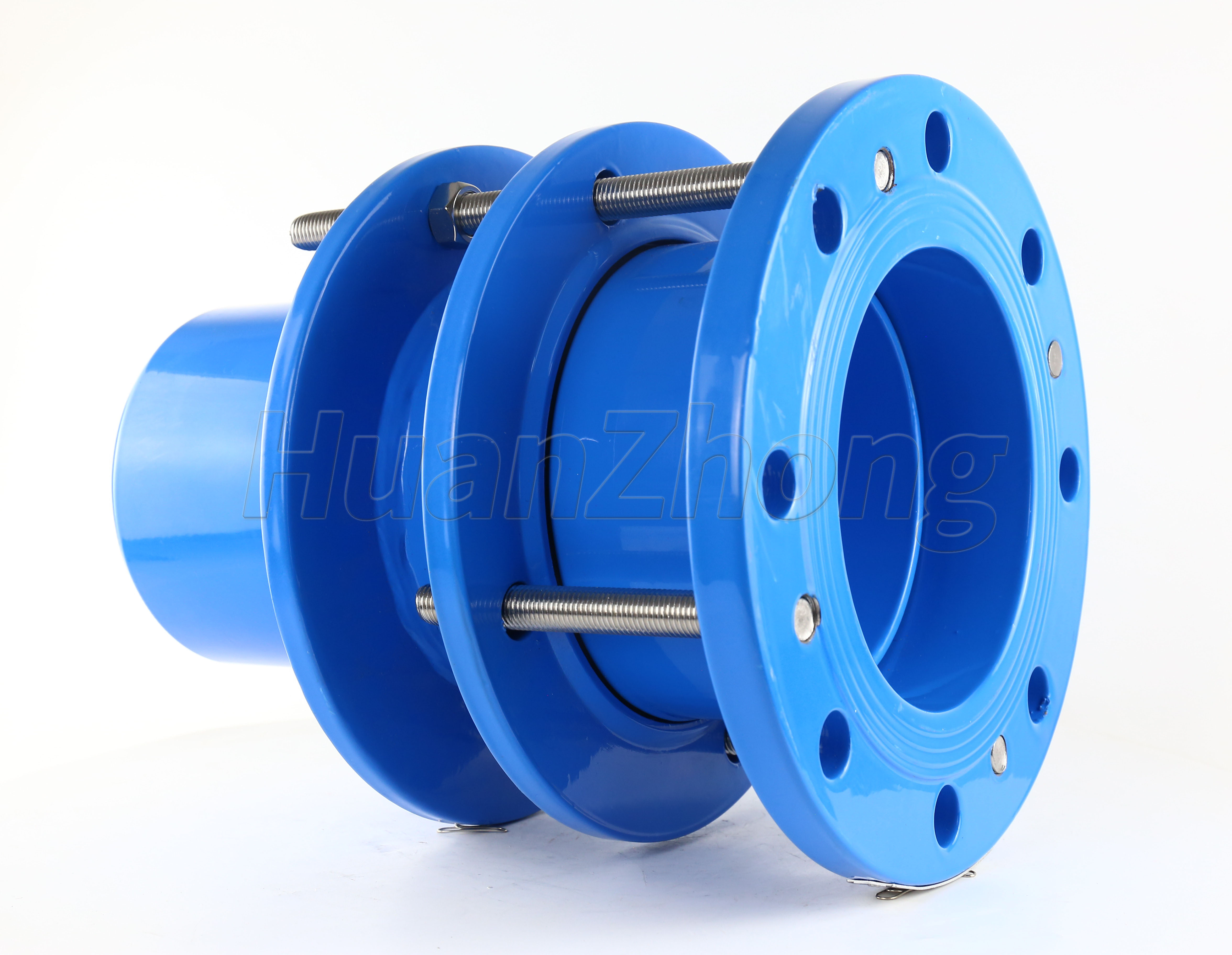

Working Pressure of Steel Transmission Expansion Joint. The working pressure of steel transmission expansion joints is a critical factor to consider when selecting and designing these components for pipeline systems. The working pressure not only determines the strength and durability of the expansion joint but also ensures the safe and efficient operation of the overall system. In this article, we will discuss the significance of working pressure in steel transmission expansion joints and the factors that influence its determination.

Working pressure refers to the maximum pressure that an expansion joint can safely withstand while maintaining its integrity during operation. It is essential to choose an expansion joint with a working pressure that exceeds or is equal to the maximum pressure expected in the pipeline system. Failure to consider the working pressure can result in catastrophic consequences such as leaks, bursts, or complete failure of the expansion joint, leading to downtime, costly repairs, and potential safety hazards.

Several factors influence the determination of the working pressure of steel transmission expansion joints:

System Requirements: The working pressure of an expansion joint is directly related to the maximum pressure expected in the pipeline system. It is crucial to gather accurate data regarding the operating pressure, including the normal working pressure, maximum pressure during peak flow conditions, and potential pressure spikes due to water hammer or other transient events. The working pressure of the expansion joint should exceed these pressure values to ensure its safe operation.

Material Selection: The choice of materials for the expansion joint plays a significant role in determining its working pressure. Steel is a commonly used material for high-pressure applications due to its strength, durability, and inherent ability to withstand high pressures. The material selection should consider factors such as the fluid being conveyed, temperature variations, corrosion resistance, and compatibility with the surrounding pipeline materials.

Design Considerations: The design of the steel transmission expansion joint should be optimized to handle the anticipated pressure conditions. Factors such as the number and shape of the convolutions, thickness of the bellows, reinforcement methods, and end connections all contribute to the working pressure capacity of the expansion joint. Compliance with industry standards, codes, and regulations is essential to ensure the design meets the required safety and performance factors.

Testing and Certification: Steel transmission expansion joints should undergo rigorous testing to determine their working pressure capacity. Various tests, including hydrostatic pressure testing, cyclic fatigue testing, and burst testing, are performed to verify the structural integrity and pressure resistance of the expansion joint. Additionally, certification from recognized third-party agencies provides assurance of the expansion joint's working pressure capability and compliance with industry standards.

In conclusion, the working pressure of steel transmission expansion joints is a critical parameter in selecting and designing these components for pipeline systems. It is essential to consider the system requirements, material selection, design considerations, and testing and certification to ensure the expansion joint can safely withstand the expected pressure conditions. By selecting an expansion joint with an appropriate working pressure capacity, operators can ensure the reliable and efficient operation of their pipeline systems while minimizing the risks of leaks, failures, and downtime.