Expansion joint DN800 capacity to withstand internal pressure.

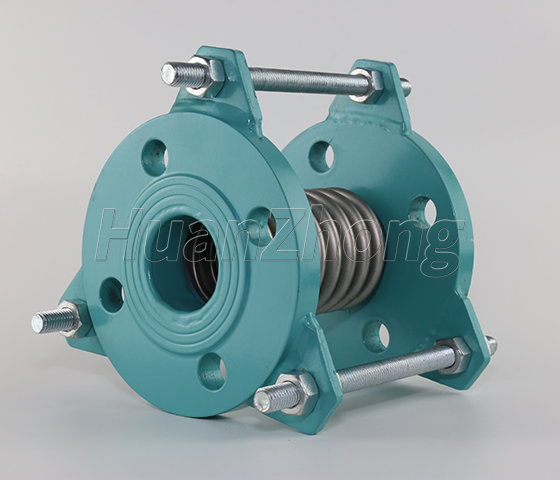

Expansion joint DN800 capacity to withstand internal pressure. Expansion joints play a critical role in accommodating the movement and thermal expansion of pipelines, ducts, and other structures. DN800 refers to the nominal diameter of the expansion joint, which is approximately 800 mm. In this article, we will explore the capacity of an expansion joint with a DN800 size to withstand internal pressure, highlighting its design considerations, materials, and safety factors.

The capacity of an expansion joint to withstand internal pressure is primarily determined by its design and construction. The design process takes into account various factors such as operating conditions, system parameters, and safety requirements. One crucial consideration is the maximum internal pressure that the expansion joint will be subjected to during normal operation.

To ensure the expansion joint's ability to withstand internal pressure, engineers carefully select materials with high strength and resistance to pressure. Common materials used for DN800 expansion joints include stainless steel, carbon steel, or other alloys that can handle the anticipated pressure levels. These materials are chosen for their mechanical properties, including tensile strength, yield strength, and ductility.

During the design phase, engineers calculate the necessary wall thickness and reinforcement to meet the required pressure capacity. Factors such as the fluid type, operating temperature, and pressure fluctuations are considered to determine the appropriate safety factors. Safety factors are incorporated to account for uncertainties and provide an extra margin of safety in the design.

The manufacturing process of expansion joints involves precision and strict quality control to ensure their integrity. Welding and fabrication techniques are employed to create strong and reliable joints. Non-destructive testing methods, such as ultrasonic testing and radiography, are often used to detect any defects or imperfections that could compromise the joint's pressure resistance.

In addition to the design and materials, the installation and maintenance of expansion joints also contribute to their ability to withstand internal pressure. Proper installation techniques, such as correct alignment and anchoring, are crucial for maintaining the joint's integrity. Regular inspections and maintenance, including visual checks and leak testing, are essential for identifying any potential issues or deterioration that could affect the joint's pressure capacity.

It is important to note that the pressure capacity of an expansion joint is not solely determined by its nominal diameter (DN800 in this case). The maximum internal pressure that an expansion joint can withstand depends on various factors, such as its design, materials, safety factors, and operating conditions. Therefore, it is crucial to consult the manufacturer's specifications and guidelines to ensure that the expansion joint is suitable for the specific pressure requirements of the application.

In conclusion, the capacity of an expansion joint with a DN800 size to withstand internal pressure is determined by its design, materials, and safety factors. Engineers carefully consider factors such as operating conditions and system parameters during the design process to ensure the joint's integrity. High-strength materials and precise manufacturing techniques are employed to create joints capable of withstanding the anticipated pressure levels. Proper installation, regular maintenance, and adherence to manufacturer guidelines are also essential for maintaining the joint's pressure capacity. By considering these factors, engineers can ensure the safe and reliable operation of DN800 expansion joints in applications where internal pressure is a concern.