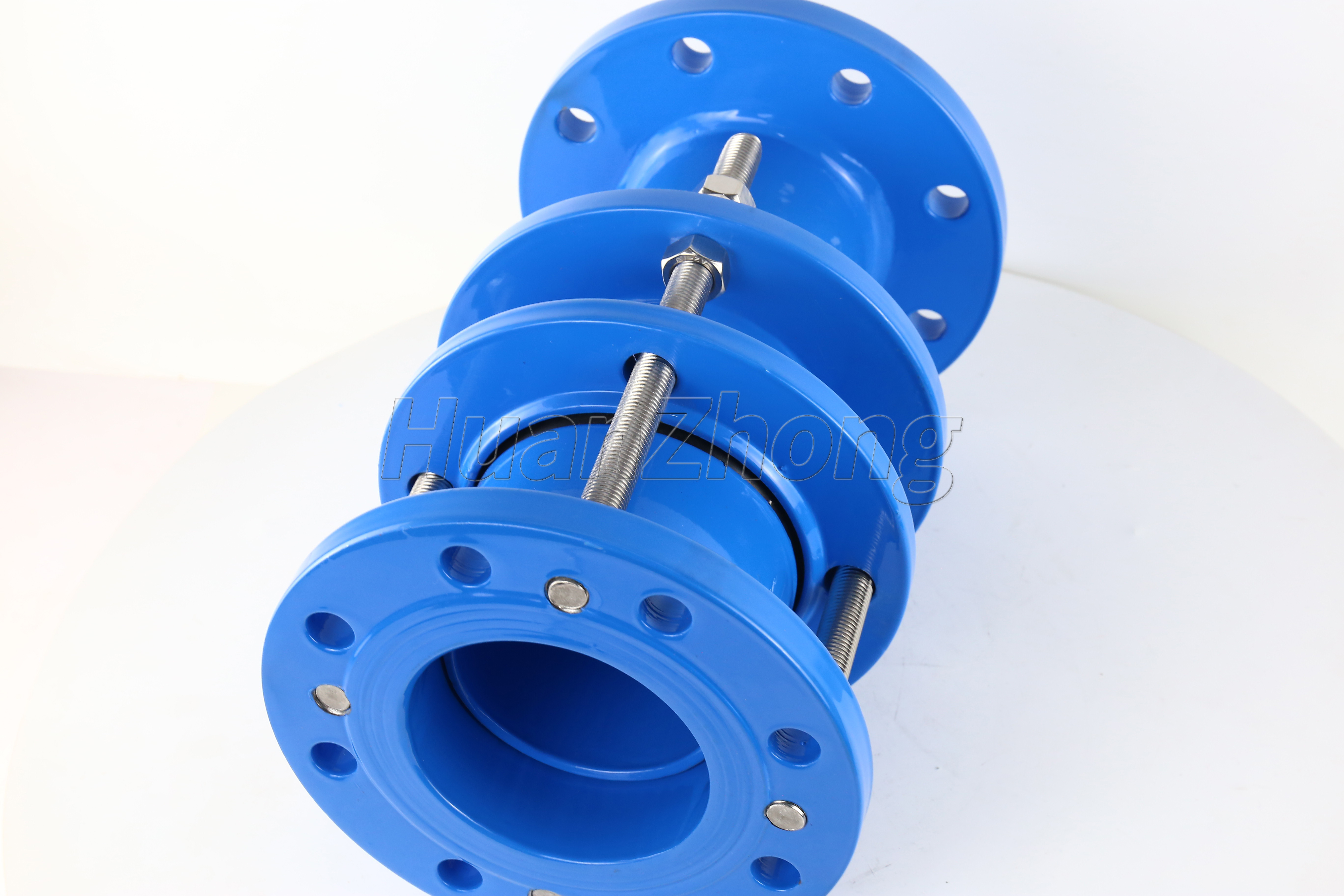

Flange type loose sleeve expansion joint installation form.

Flange type loose sleeve expansion joint installation form.

Flange type loose sleeve expansion joints are commonly used in piping systems to accommodate thermal expansion, vibration, and misalignment. In this article, we will discuss the installation form of flange type loose sleeve expansion joints and the benefits they offer.

The installation of flange type loose sleeve expansion joints involves several steps to ensure proper functioning and longevity. Here is an overview of the installation process:

Preparation: Before installation, it is crucial to inspect the expansion joint and accompanying flanges for any damage or defects. Ensure that the joint and flanges are compatible with the system's operating conditions, including pressure, temperature, and fluid compatibility. Properly clean and inspect the pipes and flanges to remove any dirt, debris, or contaminants that may impact the joint's performance.

Alignment: Carefully align the flange type loose sleeve expansion joint with the respective flanges. Ensure that the joint is properly centered and aligned with the pipe ends to maintain a uniform gap on both sides. Misalignment can lead to stress concentrations and premature failure, so it is essential to use alignment tools, such as shims or spacer bars, to achieve proper alignment.

Bolt Torque: Begin tightening the bolts in a crisscross pattern, gradually increasing the torque evenly on all bolts. Refer to the manufacturer's guidelines or technical specifications for the recommended bolt tightening torque values. Avoid over-tightening, as it can damage the joint or affect its flexibility. Proper bolt torque ensures a reliable and leak-free connection between the expansion joint and the flanges.

Pipe Support: Provide proper support for the pipes on both sides of the flange type loose sleeve expansion joint. Support structures, such as pipe hangers or supports, should be designed to handle the weight of the pipes and compensate for vertical movement. These supports help to prevent excessive stress on the expansion joint and ensure its proper functioning.

Flexibility: Verify that the installed flange type loose sleeve expansion joint can move and flex according to the expected thermal expansion and contraction, as well as the system's vibration and movement. Ensure that the joint has enough clearance and freedom to accommodate these movements without any restrictions or obstructions. This helps to prevent stress on the joint and potential damage to the piping system.

Flange type loose sleeve expansion joints offer several benefits in piping systems, including:

Absorption of Movement: The flexible design of these expansion joints allows them to absorb thermal expansion, vibration, and misalignment in the system, reducing stress and preventing damage to the pipes, valves, and equipment. This helps to extend the lifespan of the system and minimize the need for repairs or replacements.

Sealing and Leakage Prevention: Flange type loose sleeve expansion joints provide a reliable and leak-free connection between the pipes and flanges, thanks to their integrated sealing mechanism. The joint's design ensures a tight seal, preventing any leakage or loss of fluid from the system, enhancing safety and operational efficiency.

Easy Installation and Maintenance: These expansion joints are relatively simple to install and maintain, saving time and labor costs. Their flanged connection allows for easy disassembly and reassembly during maintenance or repair activities. Additionally, the loose sleeve design simplifies inspection and cleaning of the joint, ensuring its optimal performance.

In conclusion, the installation of flange type loose sleeve expansion joints is an essential aspect of ensuring the proper functioning of piping systems. By following the correct installation procedures and considering the benefits these expansion joints offer, operators can enhance the system's reliability, flexibility, and longevity.