Stainless steel bellows compensator working conditions selection principle.

Stainless steel bellows compensator working conditions selection principle. The selection of working conditions for stainless steel bellows compensators is crucial to ensuring their optimal performance and longevity. These compensators are widely used in various industries to absorb thermal expansion, vibration, and misalignment in piping systems. In this article, we will discuss the principle of selecting working conditions for stainless steel bellows compensators.

First and foremost, one must consider the temperature range in which the compensator will operate. Stainless steel bellows are designed to withstand a wide range of temperatures, but it is essential to ensure that the compensator is suitable for the specific temperature conditions it will be subjected to. High temperatures can cause the bellows to lose their elasticity, leading to premature failure. On the other hand, extremely low temperatures can make the bellows brittle and prone to cracking. Therefore, selecting a compensator with the appropriate temperature rating is crucial.

Another important factor to consider is the pressure rating of the compensator. The pressure rating determines the maximum pressure that the bellows can withstand without any damage. It is essential to select a compensator that can handle the maximum pressure expected in the piping system. Failure to do so can result in catastrophic consequences, including leaks, pipe bursts, or even equipment damage.

In addition to temperature and pressure ratings, the movement capability of the bellows compensator must also be considered. The compensator should be able to absorb the required amount of axial, lateral, and angular movements in the piping system. Overlooking the movement capability can lead to excessive stress on the bellows, reducing their lifespan and effectiveness in compensating for thermal expansion and vibrations.

The corrosive nature of the fluid or gas flowing through the piping system should also be taken into account. Stainless steel bellows are generally resistant to corrosion, but selecting the correct material and surface treatment can enhance their resistance to specific corrosive agents. This ensures that the compensator will have a longer service life and can withstand the effects of corrosion in the working environment.

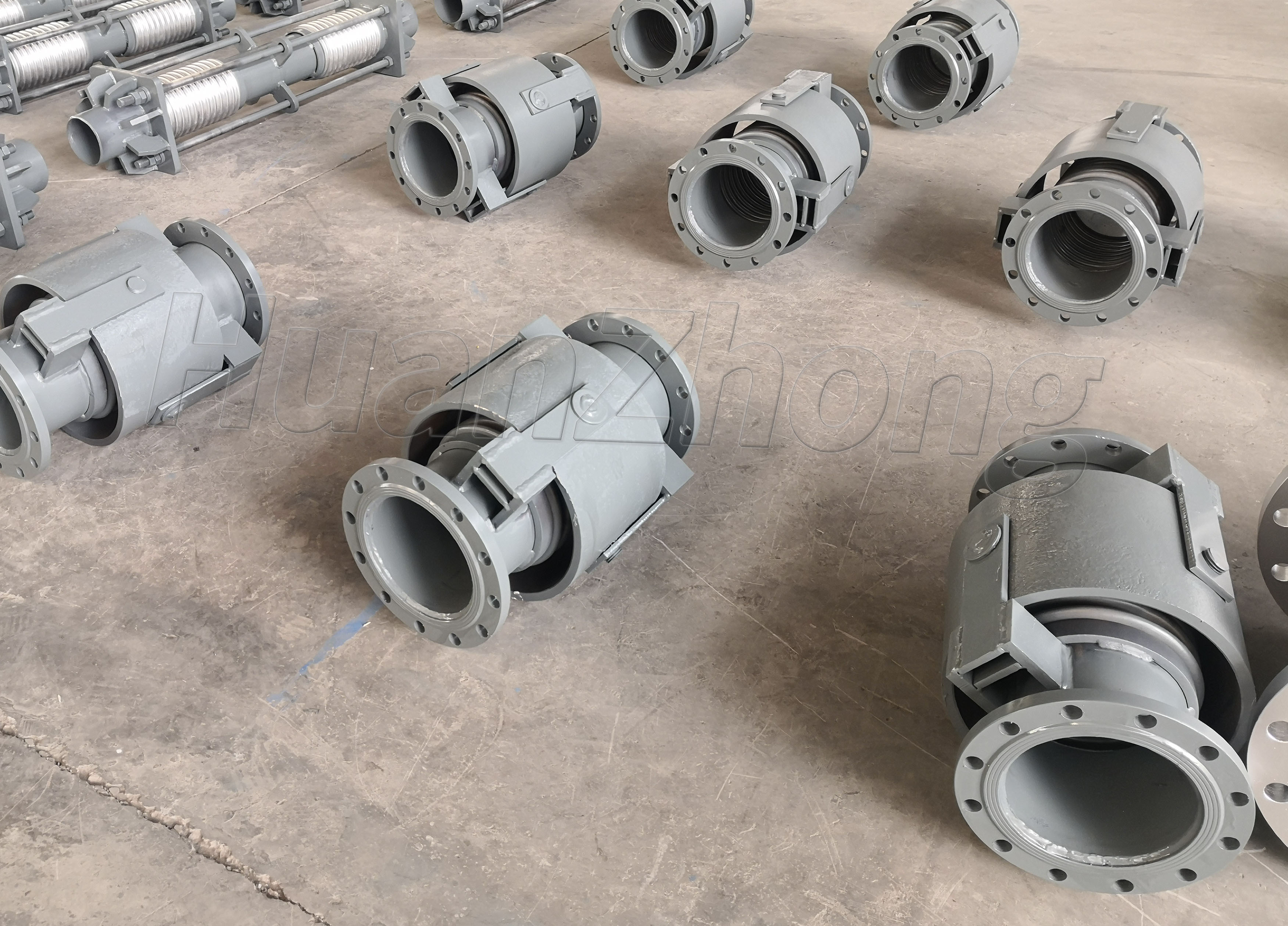

Furthermore, the size and dimensions of the compensator should be chosen based on the pipe size and installation requirements. Properly sizing the compensator is crucial to ensure that it can effectively absorb the thermal expansion and vibrations of the system. The installation method, such as flanged or welded connections, should also be considered when selecting the compensator to ensure compatibility with the existing piping system.

Lastly, it is essential to consider any additional requirements specific to the application. These may include compliance with industry standards, such as ASME, PED, or ISO certifications, as well as any specific performance criteria or vibration isolation requirements.

In conclusion, the selection of working conditions for stainless steel bellows compensators involves considering temperature, pressure, movement capability, corrosion resistance, size, installation requirements, and any other application-specific requirements. By diligently assessing these factors, one can ensure the proper functioning and longevity of the compensators, contributing to the overall efficiency and safety of the piping system.