Stainless steel metal expansion joints how to pay attention to insulation and routine maintenance?

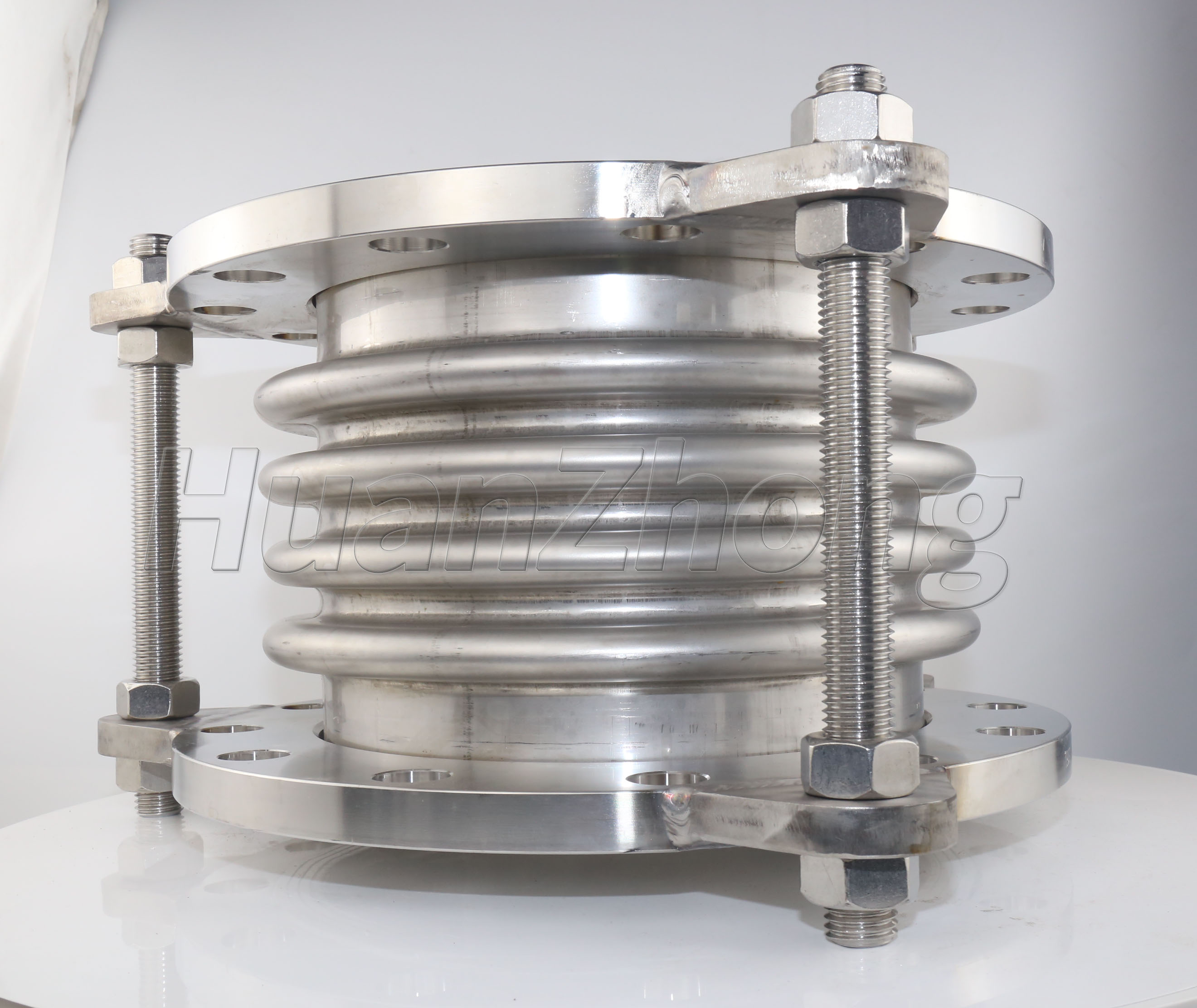

Stainless steel metal expansion joints how to pay attention to insulation and routine maintenance? Stainless steel metal expansion joints are important components in pipeline systems, as they provide flexibility to accommodate thermal expansion, vibrations, and movements. To ensure their optimal performance and longevity, it is crucial to pay attention to insulation and routine maintenance. In this article, we will discuss the importance of insulation and provide guidelines for routine maintenance of stainless steel metal expansion joints.

Insulation for Stainless Steel Metal Expansion Joints: Insulation plays a vital role in protecting stainless steel metal expansion joints from adverse environmental conditions, minimizing heat loss, and reducing the risk of thermal shock. Here are some key points to consider:

Temperature insulation: Determine the temperature range your expansion joints will be exposed to and select insulation materials with suitable thermal resistance. Insulation should be capable of withstanding extreme temperatures and preventing heat transfer.

Moisture protection: Moisture can lead to corrosion and reduce the effectiveness of insulation. Ensure that the insulation material has a moisture barrier or use additional waterproofing measures to prevent water ingress.

Insulation thickness: Properly calculate the insulation thickness to achieve the desired thermal insulation. Consider factors such as operating temperature, ambient conditions, and the material's thermal conductivity.

Insulation covers: Install protective covers over the insulation to shield it from physical damage, UV radiation, and other environmental impacts. Insulation covers also aid in reducing heat loss and prevent water penetration.

Routine Maintenance of Stainless Steel Metal Expansion Joints: Regular maintenance is essential to prolong the lifespan and ensure the trouble-free operation of stainless steel metal expansion joints. Here are some maintenance guidelines:

Visual inspection: Conduct regular visual inspections to check for any signs of wear, corrosion, leakage, or damage to the expansion joints or insulation. Look for cracks, bulges, loose or missing fasteners, or any other abnormalities.

Cleaning: Keep the expansion joints clean by removing any dirt, debris, or buildup that can hinder their function or affect thermal insulation. Use suitable cleaning agents and avoid harsh chemicals that may damage the materials.

Lubrication: Depending on the type of expansion joint, lubricate movable parts such as hinges or bellows to ensure smooth operation and reduce friction.

Check fasteners: Periodically inspect and tighten fasteners to ensure proper alignment and connection between the expansion joint and adjoining pipes or equipment.

Considerations for maintenance shutdowns: If maintenance shutdowns are planned for the pipeline system, include the inspection and repair of expansion joints in the maintenance schedule to address any potential issues or perform preventive measures.

Consultation and expert advice: If unsure about the maintenance requirements or encountering issues, consult with experienced engineers or manufacturers specializing in expansion joints. They can provide guidance on specific maintenance practices and any manufacturer-specific recommendations.

In conclusion, paying attention to insulation and performing routine maintenance is crucial for stainless steel metal expansion joints. By ensuring adequate insulation and following proper maintenance guidelines, you can enhance the performance, reliability, and longevity of your expansion joints, resulting in improved pipeline system operation.