Rubber Joint Thread Processing

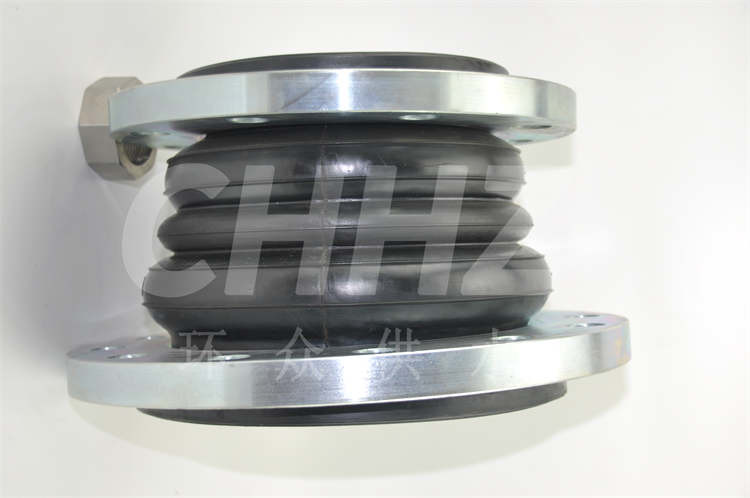

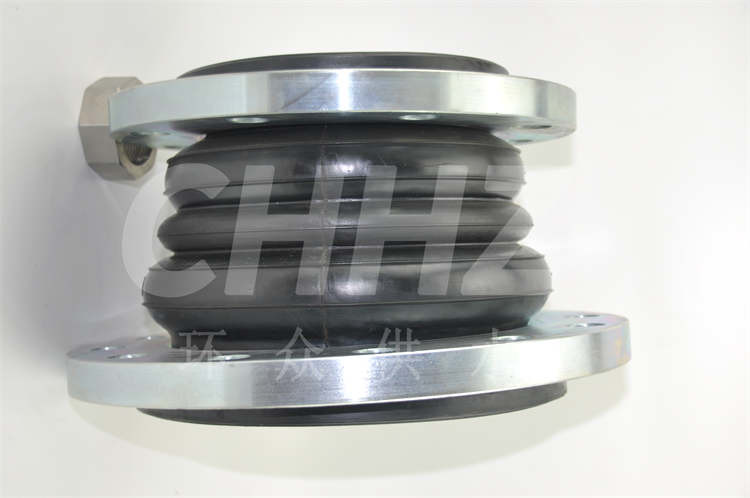

The process of machining threads on rubber joints is a vital aspect of their manufacturing, as it ensures their compatibility and effectiveness in various applications. Rubber joints, also known as expansion joints, play a crucial role in piping systems by absorbing movements, vibrations, and noise while accommodating misalignments and expansion/contraction of piping systems. Machining threads onto rubber joints enables them to be securely and conveniently connected to pipelines, valves, or other components. This article discusses the significance of rubber joint thread processing and the methods involved in this essential manufacturing step.

Importance of Rubber Joint Thread Processing: The threading process is essential for rubber joints as it allows for the creation of a secure and leak-proof connection with other components in a piping system. Various components, such as flanges, valves, or pipes, are often equipped with threaded connections, and by machining threads onto rubber joints, they can be easily integrated and sealed. Properly machined threads ensure a tight fit, preventing leaks and enhancing the overall performance and reliability of the piping system. Additionally, threaded rubber joints facilitate easier installation and maintenance, saving time and effort for operators and maintenance personnel.

Methods of Rubber Joint Thread Processing: The methods used for machining threads onto rubber joints depend on the specific design requirements, material properties, and intended application. Two common methods for processing threads on rubber joints include:

Molding: In this method, threads are directly molded or formed onto the rubber joint during the manufacturing process. The rubber material is carefully shaped and cured, incorporating the desired thread pattern into the joint. This method offers precise control over thread dimensions and ensures seamless integration with other components, resulting in a strong and durable threaded joint.

Mechanical Machining: Mechanical machining involves the use of specialized equipment, such as lathes and cutting tools, to create threads on pre-molded rubber joints. This method allows for the customization of thread specifications and is particularly useful for producing threads on rubber joints with non-standard dimensions or complex geometries. CNC (computer numerical control) machining processes can also be employed to achieve high accuracy and consistency in thread formation.

Conclusion: Rubber joint thread processing is a critical aspect of manufacturing high-quality rubber joints with threaded connections. Whether through molding or mechanical machining, the creation of precise threads on rubber joints ensures their compatibility and reliability within piping systems. By adhering to sound thread processing practices, manufacturers can produce rubber joints that meet the stringent requirements of diverse industries, such as oil and gas, water treatment, HVAC, and industrial manufacturing, thereby contributing to the safe and efficient operation of piping infrastructure.