Methods of Connecting Rubber Expansion Joints to Valves

Rubber expansion joints play a critical role in providing flexibility and movement absorption in valve systems. Properly connecting rubber expansion joints to valves is essential for ensuring the efficient operation and longevity of the entire system. In this article, we will explore various methods of connecting rubber expansion joints to valves, highlighting their significance and the considerations involved.

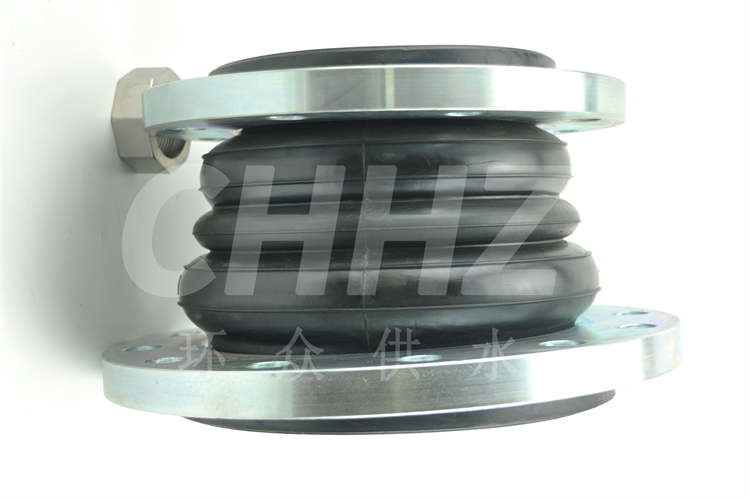

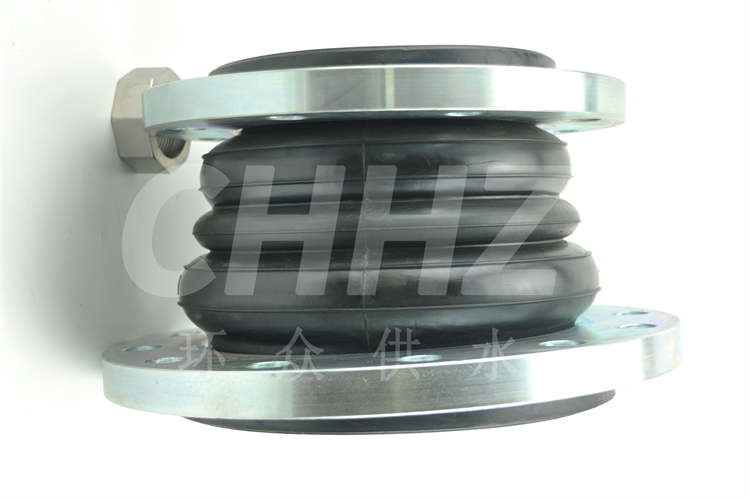

Flanged Connection: Flanged connections are one of the most common methods used to connect rubber expansion joints to valves. The joint is designed with flanged ends that align with the corresponding flanges on the valve and are secured using bolts, creating a leak-tight connection. This method facilitates easy installation, maintenance, and replacement of the expansion joint.

Threaded Connection: In some applications, a threaded connection is employed to attach rubber expansion joints to valves. With this method, the joint is equipped with threaded ends that directly screw onto the valve's threaded outlets. Threaded connections are suitable for smaller-sized joints and provide a secure means of attachment without the need for additional flanges.

Grooved Connection: For larger-diameter rubber expansion joints, a grooved connection method may be utilized. This involves using grooved-end joints that match grooved couplings on the valve. The joint and the valve are then brought together and secured using mechanical couplings, providing a reliable and flexible connection suitable for handling substantial movements.

Welded Connection: In certain valve applications, rubber expansion joints can be connected using a welded method. This involves welding the joint's ends directly to the valve's outlets, creating a robust and integral connection. Welded connections are particularly advantageous in high-temperature or high-pressure environments where a permanent and durable joint is required.

Considerations for Connection Selection: When selecting the appropriate method for connecting rubber expansion joints to valves, several factors must be considered, including the operating conditions, system pressure, temperature fluctuations, movement requirements, and the ease of maintenance and replacement. Each connection method has its advantages and limitations, and the selection should be based on the specific needs of the application.

In conclusion, the proper connection of rubber expansion joints to valves is crucial for ensuring the integrity and efficiency of the overall system. By understanding the various connection methods and their suitability for different operating conditions, engineers and installers can make informed decisions to achieve optimal performance and reliability in valve systems employing rubber expansion joints.