Rubber Flexible Joints: Are They Classified as Valves?

Rubber flexible joints, commonly known as expansion joints, play a vital role in piping systems by absorbing vibration, displacements, and providing flexibility to accommodate movement. However, it is important to clarify their classification, particularly in relation to valves within the context of fluid handling systems.

In the realm of industrial fluid handling, valves are devices that control the flow of fluids by opening, closing, or partially obstructing passageways. They serve as critical components in regulating the movement and direction of fluids within a system. On the other hand, rubber flexible joints, despite their importance in piping systems, do not fall under the category of valves.

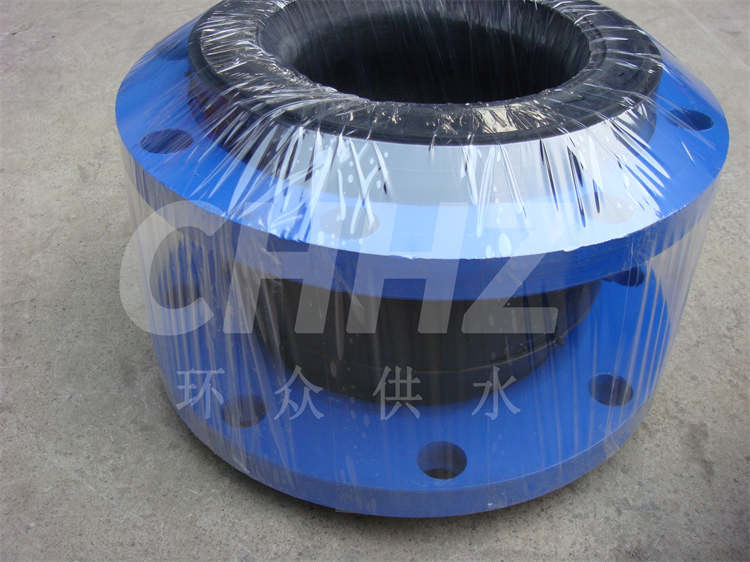

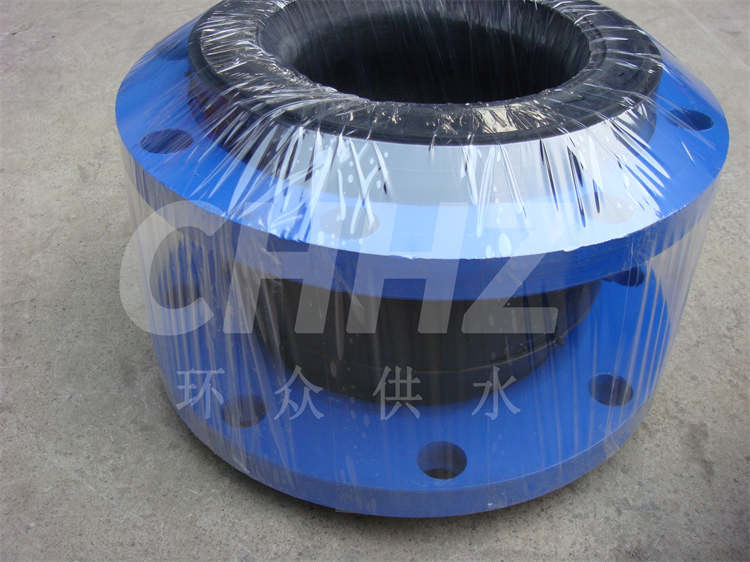

Rubber flexible joints are engineered to address specific challenges related to piping, such as thermal expansion, misalignment, and vibration. These joints consist of a flexible, rubberized material that can absorb movement and mitigate stress in pipelines, thereby safeguarding against damage and enhancing the overall integrity of the system. Their function primarily revolves around providing mechanical flexibility and damping properties, rather than controlling the flow of fluids.

Unlike valves, which actively manage the flow or pressure of fluids, rubber flexible joints operate as passive components that respond to the dynamic forces exerted on the piping system. Their design and function are dedicated to accommodating movements and displacements without impeding flow or altering the fluid characteristics. Therefore, while both valves and rubber flexible joints are integral to the efficient operation of fluid handling systems, they serve distinct and complementary roles.

In summary, rubber flexible joints, or expansion joints, do not belong to the category of valves within the domain of fluid handling systems. Their purpose lies in addressing mechanical and dynamic challenges within piping systems, such as thermal expansion and vibration, without directly influencing the flow of fluids. By understanding the unique functions of these components, engineers and practitioners can effectively optimize the performance and reliability of fluid handling systems through the appropriate selection and utilization of both valves and rubber flexible joints.