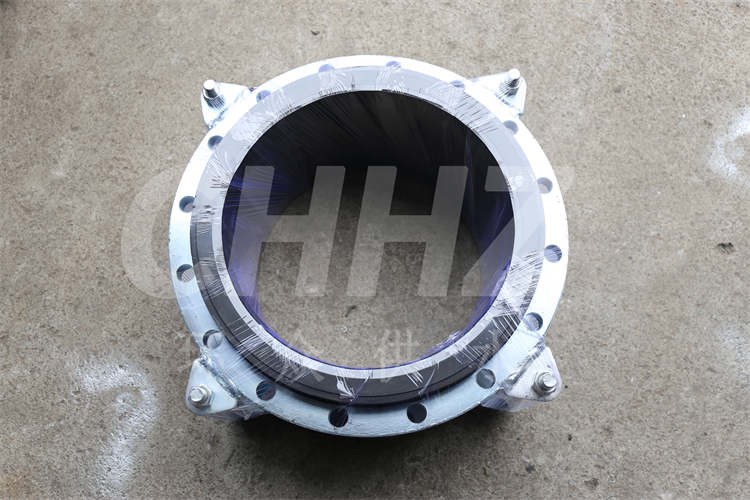

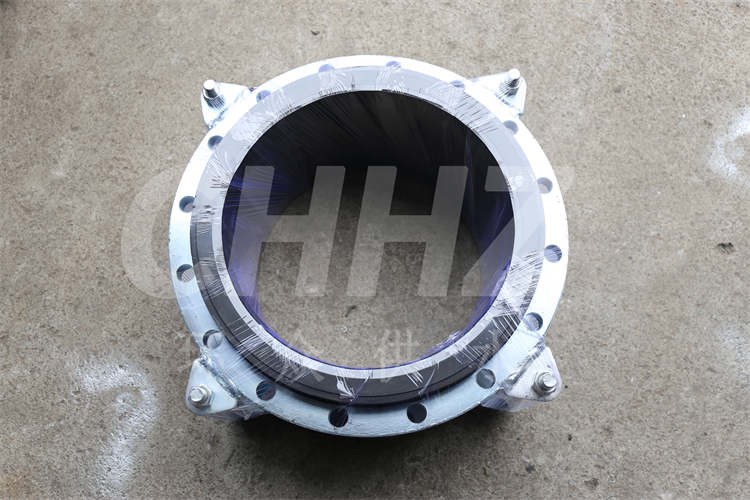

Rubber Reducing Joints

Introduction: Rubber reducing joints, also known as rubber reducer couplings, play a crucial role in piping systems where a change in pipe diameter is required. These components are designed to facilitate a smooth transition between pipes of different sizes while accommodating movement, vibration, and misalignment. In this article, we will explore the key features and benefits of rubber reducing joints in various industrial applications.

Seamless Transitions: Rubber reducing joints are engineered to provide seamless transitions between pipes of varying diameters. This feature ensures that the flow of fluids or materials through the piping system remains uninterrupted, minimizing pressure losses and improving overall system efficiency. The ability to connect dissimilar pipe sizes without abrupt changes in the flow profile is a significant advantage of these components.

Flexibility and Absorption of Vibrations: The rubber construction of reducing joints allows them to exhibit flexibility, enabling them to absorb vibrations, shocks, and noise within the piping system. This flexibility is particularly important when connecting pipes of different sizes, as it helps to mitigate the effects of pulsations and pressure surges, thereby contributing to the longevity of the pipeline infrastructure.

Movement Accommodation: Rubber reducing joints are designed to accommodate axial, lateral, and angular movements, providing flexibility in piping configurations. The capacity to accommodate movement is crucial for minimizing stress on connected pipes and equipment, which in turn reduces the risk of damage and enhances the reliability of the overall system.

Corrosion Resistance: The rubber material used in reducing joints provides a resilient barrier that is highly resistant to corrosion, ensuring durability and longevity in demanding operating environments. This corrosion resistance helps to protect the joints from the potentially corrosive nature of conveyed media, thereby maintaining the integrity of the piping system.

Easy Installation and Maintenance: These rubber reducing joints offer a straightforward installation process, allowing for efficient integration into existing or new piping systems. Additionally, the low maintenance requirements contribute to cost-effective operation and management of industrial pipelines, making them an attractive choice for various applications.

Conclusion: In conclusion, rubber reducing joints excel in providing seamless transitions, flexibility, movement accommodation, and corrosion resistance in piping systems. Their ability to connect pipes of different sizes while effectively mitigating vibrations and accommodating movement makes them an indispensable component in a wide range of industrial applications. An understanding of the unique features and benefits of rubber reducing joints is essential for engineers and industry professionals involved in the design, installation, and maintenance of piping systems.