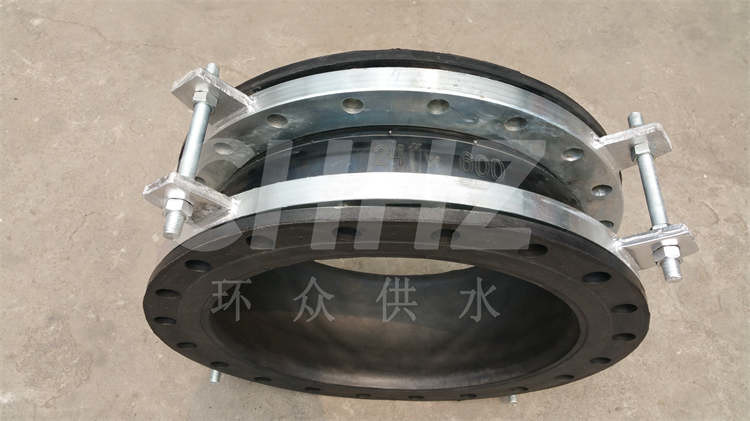

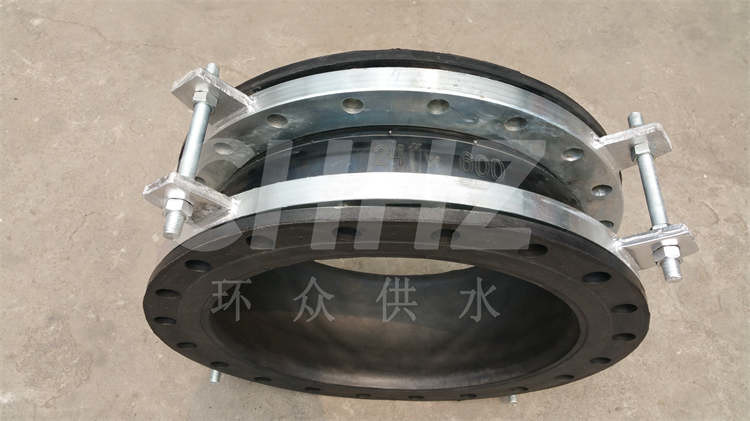

Rubber Joint Installation

When it comes to the proper installation of rubber joints, following the correct procedures is crucial to ensuring the long-term performance and stability of the joint within the piping system. Rubber joints, also known as rubber expansion joints or flexible rubber connectors, are designed to absorb vibrations, reduce noise, compensate for misalignments, and accommodate movement in piping systems. Here's a detailed guide on the installation process of rubber joints:

1. Precise Measurement: The first step in installing a rubber joint is to ensure precise measurements of the piping system. This includes accurately determining the diameter, length, and orientation of the joint so that it can be properly fitted into the system.

2. Pipe Preparation: Before installing the rubber joint, the pipe ends should be cleaned thoroughly to remove any debris, dirt, or rust that may affect the sealing and bonding of the joint.

3. Alignment: Proper alignment of the pipes is crucial before installing the rubber joint. The pipes should be aligned to ensure that the joint can effectively absorb movements and vibrations without causing stress on the piping system.

4. Secure Attachment: The rubber joint should be securely attached to the piping system using appropriate hardware such as bolts and nuts. The attachment should be tight enough to prevent leakage but not excessively tight, which could lead to unnecessary stress on the joint.

5. Avoid Overextension: Care should be taken to avoid overextension of the joint during installation. Overstretching the rubber joint may compromise its ability to absorb vibrations and movements effectively.

6. Sealant Application: Using a recommended sealant or lubricant at the joint interface can help ensure a proper seal and ease the installation process.

7. Inspection: After installation, a thorough inspection of the rubber joint and the entire piping system should be conducted to ensure that everything is correctly in place and that there are no signs of damage or misalignment.

8. Testing: Once the rubber joint is installed, it is advisable to conduct a pressure and leakage test to verify the integrity of the joint and to ensure that it functions as intended.

Proper installation of rubber joints is essential to ensure the optimal performance of piping systems. By following these installation guidelines, the functionality, durability, and reliability of rubber joints can be ensured, ultimately contributing to the overall efficiency and safety of the piping infrastructure.