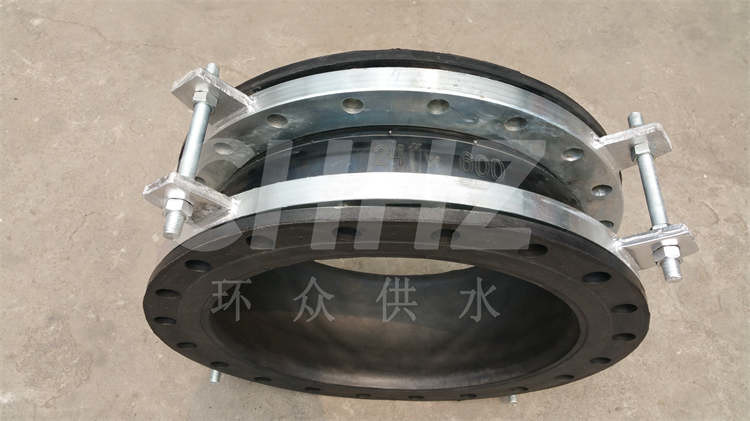

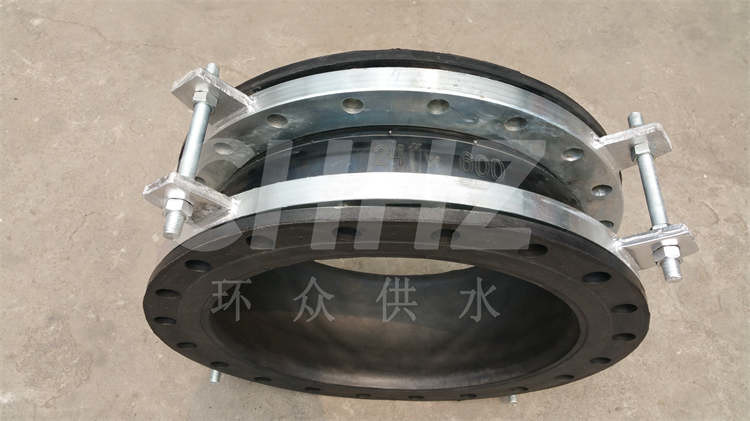

Automotive Glass Rubber Joint Mold

The automotive glass rubber joint mold is an indispensable component in the manufacturing process of automotive glass rubber seals. This mold plays a crucial role in shaping and forming rubber materials into precise seals that are essential for maintaining the integrity and functionality of automotive glass components. In this article, we will delve into the key features and benefits of the automotive glass rubber joint mold.

Key Features:

Precision Design: The mold is meticulously designed to replicate the intricate profiles and dimensions required for automotive glass rubber seals. Its precision design ensures that the resulting seals fit seamlessly into the designated areas, providing effective weatherproofing and structural support for automotive glass installations.

Robust Construction: The mold is crafted from high-quality materials that can withstand the rigors of repetitive molding processes, ensuring long-term durability and consistent performance. Its robust construction contributes to maintaining dimensional accuracy and surface finish quality in the molded rubber seals.

Customization Capabilities: The mold can be customized to accommodate specific design requirements, allowing for the production of a variety of rubber seals tailored to different automotive glass applications. Its customization capabilities enable manufacturers to address diverse sealing needs across vehicle models and glass components.

Efficient Cooling and Ejection Systems: The mold is equipped with efficient cooling and ejection systems to optimize the molding process. These features aid in the rapid and controlled cooling of the rubber material within the mold cavity, facilitating the smooth release of finished rubber seals with minimal production cycle times.

Benefits:

Consistent Quality: The precision design and robust construction of the automotive glass rubber joint mold contribute to the consistent production of high-quality rubber seals. This ensures that the seals meet stringent standards forEnhanced Productivity: The mold's customization capabilities and efficient cooling and ejection systems promote enhanced productivity in the manufacturing process. It allows for swift adaptation to varying sealing requirements and facilitates efficient production throughput, resulting in reduced lead times and increased output.

Cost Efficiency: By producing consistently high-quality rubber seals with minimal waste and rework, the mold contributes to overall cost efficiency in automotive glass seal manufacturing. It helps in reducing material consumption, improving production yield, and optimizing manufacturing resources.

Versatility and Adaptability: The mold's ability to accommodate diverse design requirements and support multiple sealing applications underscores its versatility and adaptability to different automotive glass assembly needs. This versatility allows for flexibility in addressing changing market demands and product variations.

In conclusion, the automotive glass rubber joint mold is an essential tool for producing precision-engineered rubber seals that contribute to the performance and durability of automotive glass installations. Its precision design, robust construction, customization capabilities, efficient cooling and ejection systems, along with the associated benefits of consistent quality, enhanced productivity, cost efficiency, versatility, and adaptability, make it a vital asset in the automotive manufacturing sector.