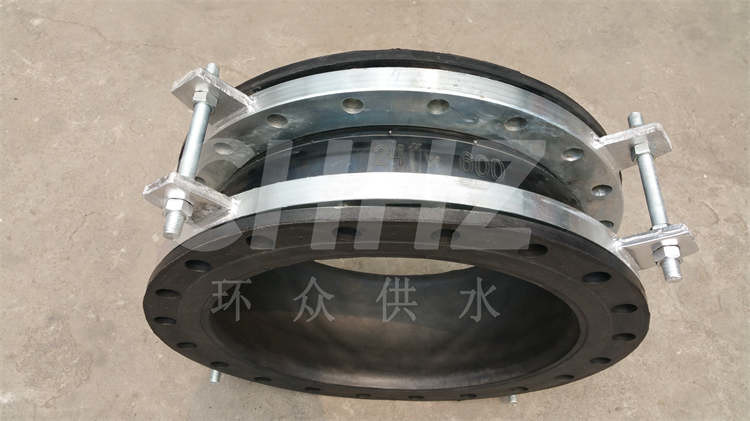

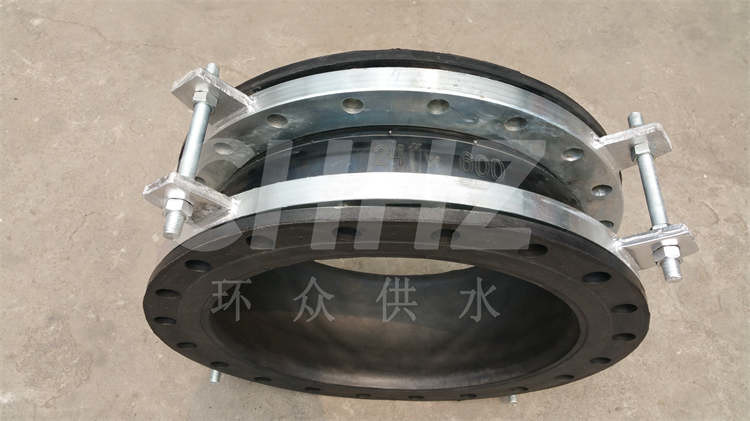

the installation of rubber flexible joints

Rubber flexible joints, also known as rubber expansion joints, play a crucial role in piping systems by absorbing vibration, reducing noise, and compensating for movement due to thermal expansion or contraction. Proper installation is essential to ensure the effective functioning of these joints.

The installation process typically involves the following steps:

Pre-Installation Inspection: Before installation, carefully inspect the rubber flexible joints to ensure they are free from any damage or defects. Review the manufacturer's specifications and installation instructions to ensure compliance.

Piping System Assessment: Evaluate the specific locations in the piping system where the rubber flexible joints will be installed. Ensure that the system is adequately supported and aligned to accommodate the joints.

Assembly and Alignment: Properly position the rubber flexible joints within the piping system, ensuring correct alignment. Secure the joints in place using appropriate fasteners and hardware.

Connection to Piping: Connect the rubber flexible joints to the piping system, taking care to follow the recommended installation techniques provided by the manufacturer.

Testing and Inspection: After installation, conduct testing and inspection to verify the proper functioning of the joints. This may involve conducting pressure tests or other relevant assessments.

Maintenance and Monitoring: Regularly inspect and monitor the rubber flexible joints as part of routine maintenance to identify any signs of wear, damage, or performance issues.

It is important to always follow the manufacturer's guidelines and industry best practices when installing rubber flexible joints to ensure the integrity and longevity of the piping system.