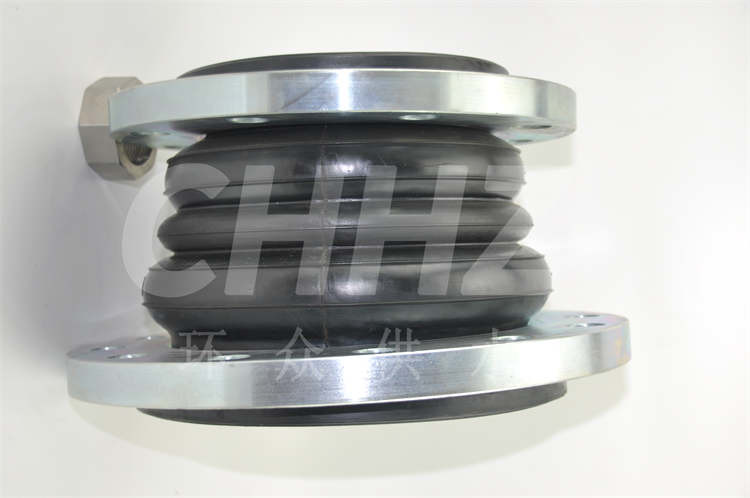

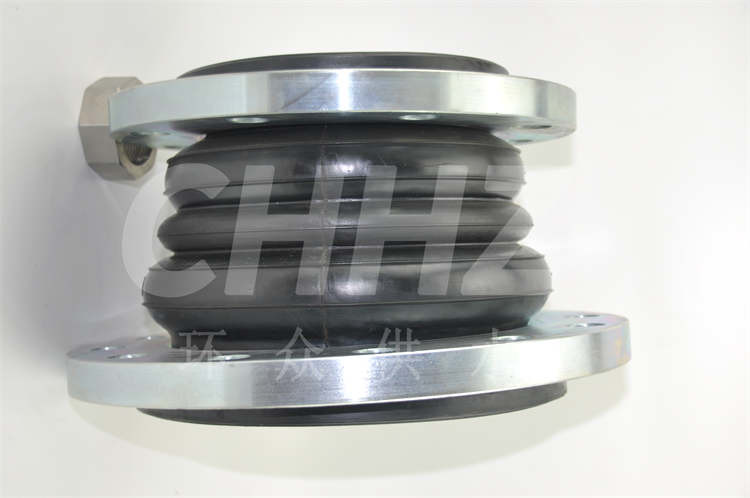

Processing of Card Sleeve Rubber Joints

Card sleeve rubber joints are essential components used in piping systems to absorb vibration, reduce noise, and compensate for thermal expansion and contraction. The processing of card sleeve rubber joints involves several critical steps to ensure their integrity and performance in various industrial applications.

The manufacturing process of card sleeve rubber joints begins with the selection of high-quality raw materials, typically natural rubber or synthetic elastomers, compounded with additives such as fillers, plasticizers, and vulcanizing agents. The rubber compound is carefully mixed to achieve the desired mechanical and chemical properties, ensuring superior resilience and resistance to environmental factors.

The next step in the processing of card sleeve rubber joints involves shaping the rubber compound into the specific design of the joint, incorporating features such as card sleeves and flanges for connection to the piping system. This shaping process may involve molding techniques such as compression molding or injection molding, depending on the complexity of the joint's geometry and the desired production volume.

Once the rubber compound has been molded into the card sleeve rubber joint's structure, it undergoes the vulcanization process. Vulcanization is a critical step that involves heating the rubber to a specified temperature and combining it with curing agents, typically sulfur, to create cross-links between the polymer chains. This cross-linking process imparts the necessary durability, elasticity, and resistance to the rubber, ensuring its suitability for extended service life in demanding operating conditions.

After vulcanization, the card sleeve rubber joints are subjected to strict quality control measures to verify their dimensional accuracy and mechanical properties. Visual inspections, dimensional checks, and testing for qualities such as tensile strength, flexibility, and resistance to pressure are conducted to ensure that the rubber joints meet the required specifications for performance and safety.

Furthermore, the processing of card sleeve rubber joints may include additional steps such as surface treatments to enhance their corrosion resistance, as well as the installation of protective reinforcements to extend their service life in harsh environments. These measures contribute to the overall quality and reliability of the rubber joints in demanding industrial applications.

In conclusion, the processing of card sleeve rubber joints involves a series of meticulous steps, from raw material selection to vulcanization and quality control, to ensure the production of high-quality components for piping systems. Manufacturers adhere to stringent manufacturing processes to produce card sleeve rubber joints that deliver exceptional performance, longevity, and versatility in diverse industrial settings.