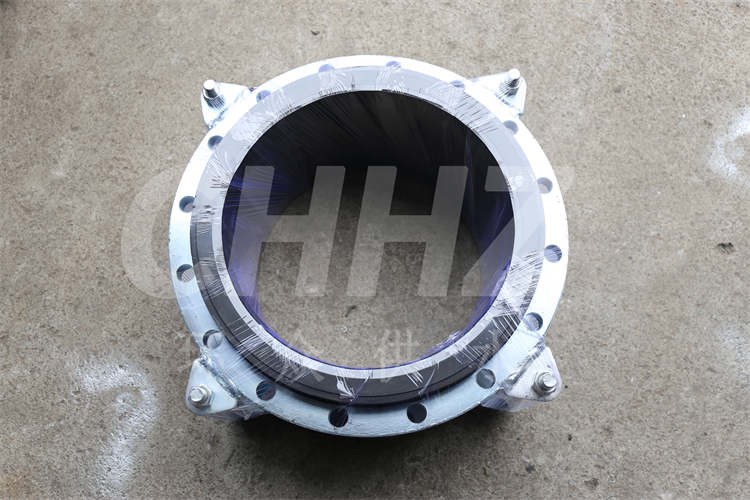

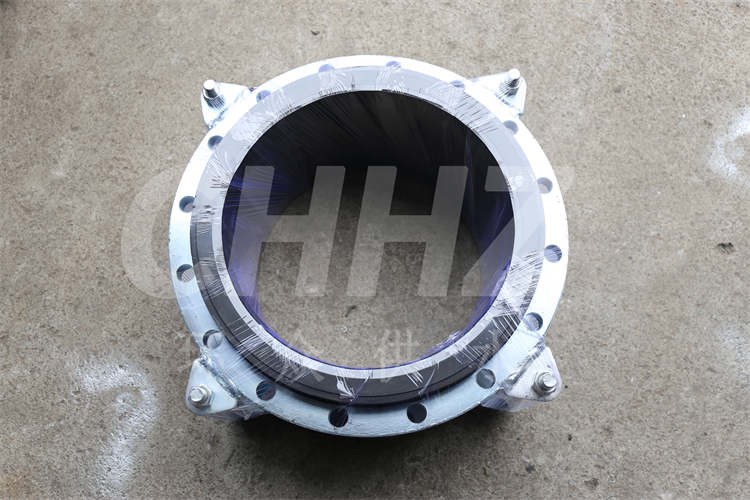

Rubber Hose Connection with Metal Fittings

Rubber hoses serve as vital components in various industries, providing flexible conveyance of fluids and materials. The connection of rubber hoses with metal fittings is fundamental to ensuring efficient and reliable fluid transfer in diverse applications. This article discusses the importance of the interface between rubber hoses and metal fittings and the methods employed for achieving secure and functional connections.

The connection between rubber hoses and metal fittings is critical in maintaining the integrity of fluid transport systems. Rubber hoses are designed to withstand the rigors of fluid conveyance, offering flexibility, resilience, and resistance to a wide range of operating conditions. On the other hand, metal fittings provide the means for securely anchoring and sealing the ends of the rubber hoses, preventing leaks and ensuring proper alignment with other system components.

One of the common methods for joining rubber hoses with metal fittings involves the use of hose clamps or band clamps. These clamps, typically made of stainless steel or other durable materials, are tightened around the exterior surface of the rubber hose and secured to the barbed or threaded ends of the metal fittings. The clamping action creates a tight seal that prevents the escape of fluids and maintains the structural integrity of the connection.

In some applications, especially those involving high-pressure or critical fluid transfer, swaging or crimping techniques are employed to attach metal fittings to rubber hoses. Swaging involves the mechanical compression of the hose end around the inserted metal fitting, creating a permanent and robust connection. Similarly, crimping utilizes a hydraulic press to deform the hose and fitting, producing a secure joint that can withstand substantial pressure and vibration.

An alternative approach for connecting rubber hoses with metal fittings is the use of threaded connections. Threaded fittings, such as NPT (National Pipe Thread) or BSP (British Standard Pipe), are installed at the ends of the rubber hose, allowing for direct attachment to complementary threads on equipment or piping systems. Threaded connections are often sealed with the application of thread sealants or sealing washers to prevent leaks and maintain the integrity of the joint.

The selection of the appropriate method for connecting rubber hoses with metal fittings depends on factors such as operating conditions, fluid compatibility, pressure requirements, and installation constraints. Proper installation and maintenance of these connections are essential to ensure leak-free operation and optimal system performance.

In conclusion, the interface between rubber hoses and metal fittings is a crucial aspect of fluid transfer systems across various industries. The secure and efficient connection of these components is essential for maintaining the integrity of fluid conveyance, preventing leaks, and ensuring the reliability of industrial processes. The diverse methods available for joining rubber hoses with metal fittings provide flexibility in meeting the specific needs of different applications, contributing to the seamless and efficient operation of fluid transport systems.