Rubber-Lined Metal Pipe Joints: Enhancing Piping Systems

Rubber-lined metal pipe joints are a critical component in various industrial applications, providing flexibility, vibration absorption, and corrosion resistance in piping systems. These joints play a crucial role in connecting different segments of pipelines while mitigating the effects of pressure, temperature variations, and mechanical movement. This article explores the significant features and applications of rubber-lined metal pipe joints.

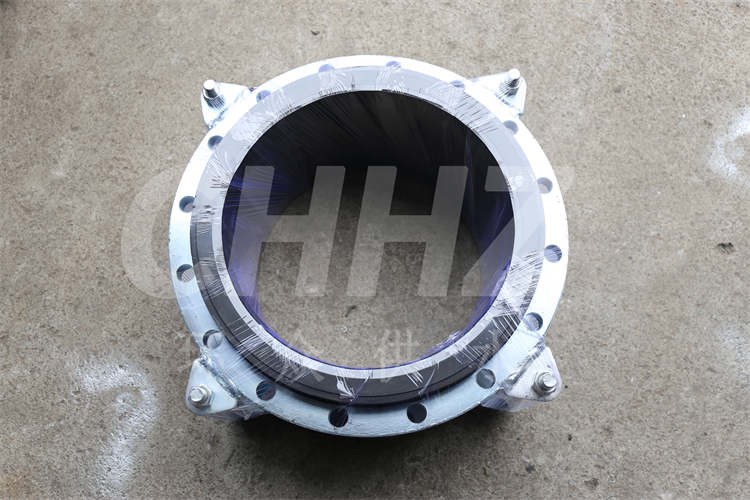

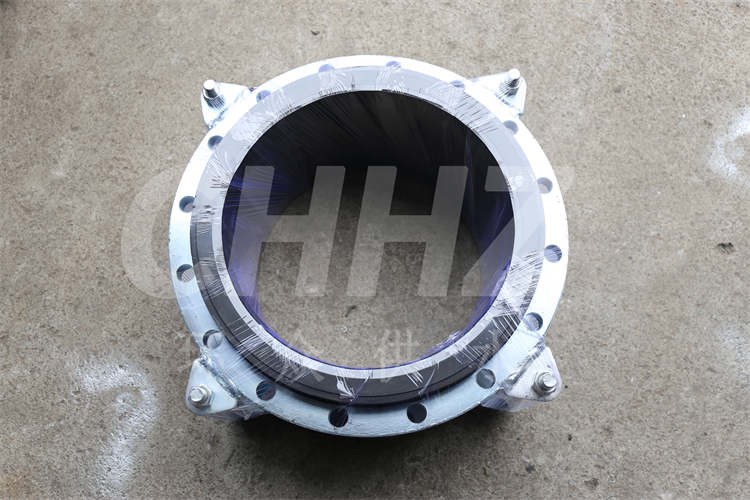

The primary function of rubber-lined metal pipe joints is to offer a flexible and durable connection between metallic pipes, compensating for misalignment, absorbing vibrations, and accommodating thermal expansion and contraction. These joints consist of a rubber lining encased in a sturdy metal shell, combining the resilience of rubber with the strength of metal to provide an effective and long-lasting solution for piping systems.

In industrial settings such as chemical plants, refineries, and petrochemical facilities, rubber-lined metal pipe joints are widely used due to their ability to withstand corrosive environments, high temperatures, and abrasive materials. The rubber lining acts as a protective barrier, safeguarding the inner metal surface from chemical attack and erosion, thereby extending the lifespan of the piping system.

Moreover, rubber-lined metal pipe joints effectively reduce noise and dampen vibrations, enhancing the safety and efficiency of industrial operations. By isolating and dissipating vibrations caused by pumps, compressors, and turbulent fluid flow, these joints contribute to a quieter and more stable working environment while minimizing the risk of structural damage and equipment failure.

The installation and maintenance of rubber-lined metal pipe joints are relatively straightforward, making them a cost-effective choice for industrial facilities. Additionally, their versatility in accommodating angular and axial movement ensures that stress and strain on the piping system are minimized, leading to reduced maintenance requirements and enhanced overall system reliability.

In conclusion, rubber-lined metal pipe joints are indispensable for a wide range of industrial applications, offering a combination of flexibility, durability, and corrosion resistance. Their ability to mitigate the effects of pressure, temperature, and mechanical forces makes them essential components in ensuring the integrity and performance of piping systems across various industries. As industrial operations continue to evolve, the importance of rubber-lined metal pipe joints in maintaining safe, efficient, and reliable piping networks remains paramount.