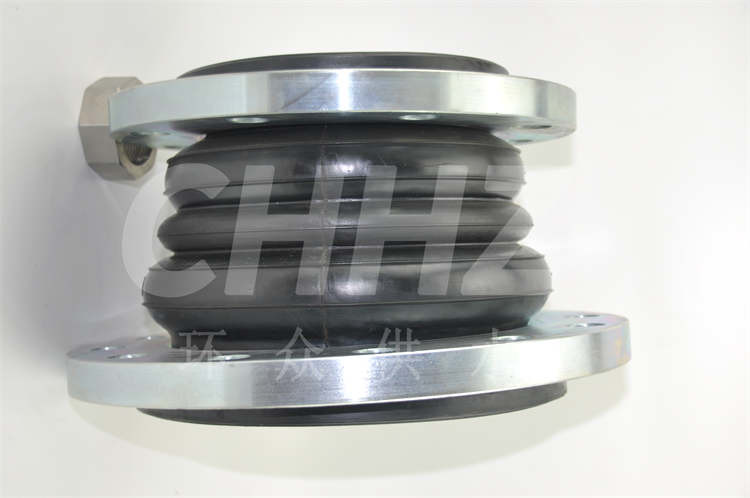

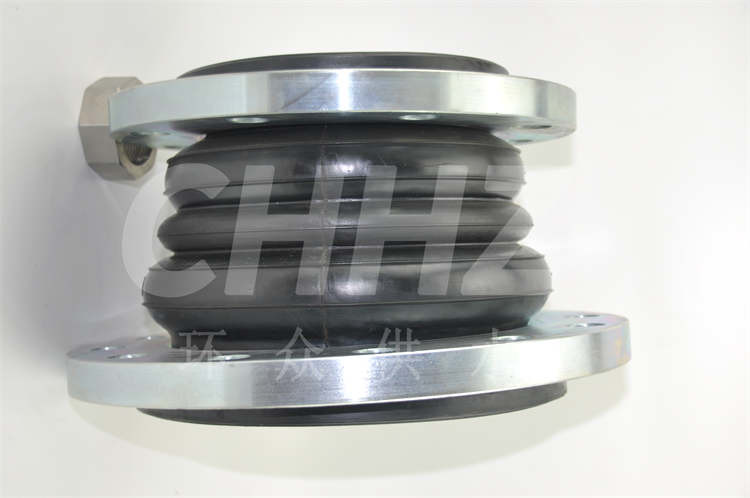

Rubber Expansion Joint Valve Direct Connection

Rubber expansion joints, also known as rubber flex connectors, are commonly used in piping systems to absorb movement, reduce vibration, and compensate for misalignment or thermal expansion. When connecting a rubber expansion joint directly to a valve, specific procedures should be followed to ensure a proper and secure installation. Here are the steps to directly connect a rubber expansion joint to a valve.

Step 1: Verify Compatibility Before the installation, it is crucial to verify that the rubber expansion joint and valve are compatible in terms of size, pressure rating, temperature, and chemical compatibility. Using an incompatible joint or valve could lead to premature failure and potential hazards.

Step 2: Preparation Gather all necessary tools and equipment required for the installation, including wrenches, bolts, gaskets, and lubricant if needed. Ensure that the work area is clean and free from any obstructions.

Step 3: Positioning Position the rubber expansion joint in alignment with the valve, ensuring that there is adequate clearance for movement and that the joint is not under any undue stress or tension.

Step 4: Flange Alignment Align the bolt holes of the rubber expansion joint flange with the matching bolt holes on the valve flange. Make sure that the flanges are parallel and properly positioned before inserting the bolts.

Step 5: Bolt Installation Insert the bolts into the bolt holes, and hand-tighten them to secure the joint to the valve. Ensure that the bolts are evenly tightened in a crisscross pattern, gradually and evenly tightening each bolt until fully secured.

Step 6: Gasket Placement If gaskets are required, insert them between the flanges to ensure a tight and secure seal. Lubricate the gaskets if necessary to facilitate a proper seal.

Step 7: Final Tightening Use a torque wrench to tighten the bolts to the manufacturer's recommended specifications. Proper torque ensures a secure connection and prevents leakage during operation.

Step 8: Inspection Upon completion of the installation, inspect the connection for any signs of misalignment or gaps. Ensure that the rubber expansion joint is free to move and is not under any strain or tension.

By following these steps, a secure and reliable connection between a rubber expansion joint and a valve can be achieved. Proper installation is crucial for ensuring the long-term performance and safety of the piping system.