Handling Rubber Joints: Best Practices and Maintenance

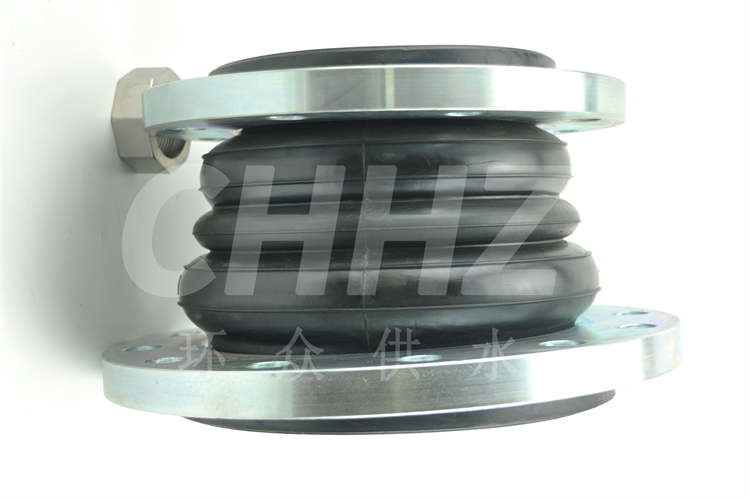

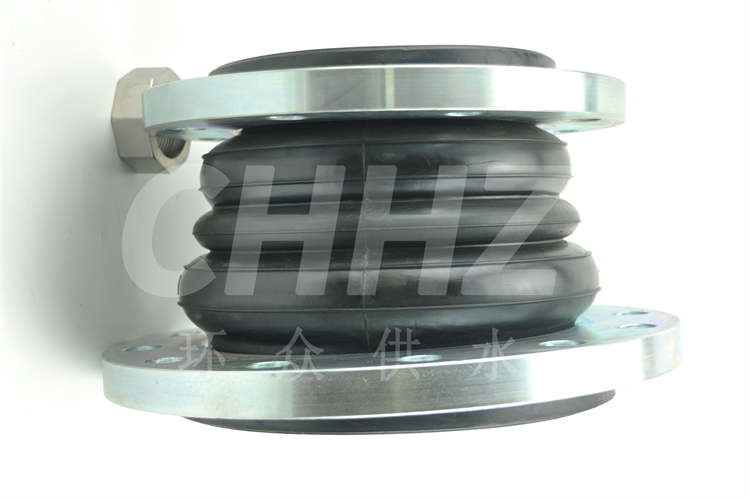

Rubber joints play a critical role in numerous industrial applications, providing flexibility and absorbing vibrations within piping systems. To ensure optimal performance and longevity, it is essential to implement proper handling and maintenance practices. This article aims to outline best practices for the handling and maintenance of rubber joints in industrial settings.

1. Proper Storage: When handling rubber joints, it is crucial to store them in a suitable environment. Ensure that the storage area is dry, well-ventilated, and away from direct sunlight or extreme temperatures. Exposure to UV radiation, high humidity, or temperature fluctuations can accelerate the degradation of rubber materials, leading to premature deterioration.

2. Installation Guidelines: Prior to installation, it is important to carefully review the manufacturer's guidelines and recommendations for installing rubber joints. Incorrect installation procedures can subject the joints to undue stress, potentially leading to premature failure. Adhering to the specified installation procedures and torque values can help prevent damage to the joints and ensure a secure and leak-free connection within the piping system.

3. Regular Inspection: Periodic inspection of rubber joints is essential to detect early signs of wear, damage, or degradation. Visual inspections should be conducted to check for cracks, bulges, or signs of deterioration. Additionally, performance assessments, such as leakage tests or vibration analysis, can help identify potential issues that require attention.

4. Maintenance Schedule: Establishing a routine maintenance schedule for rubber joints is vital for ensuring their continued functionality. This may include scheduled inspections, cleaning, and lubrication of flange connections or other components. Regular maintenance can help extend the service life of rubber joints and prevent unexpected failures.

5. Chemical Compatibility: When handling rubber joints in environments where exposure to chemicals is possible, it is imperative to ensure that the rubber material is compatible with the conveyed media. Certain chemicals or fluids may be incompatible with rubber, leading to degradation and loss of integrity. Consult with the manufacturer or a materials specialist to verify the chemical compatibility of the rubber material.

6. Training and Education: Providing training to personnel involved in the handling and maintenance of rubber joints is essential. Properly trained staff can follow recommended procedures for handling, installation, and maintenance, reducing the likelihood of errors that could compromise the performance and lifespan of rubber joints.

7. Replacement Considerations: As rubber joints age and undergo wear, it is important to establish criteria for replacement based on factors such as service life, environmental conditions, and operational demands. Developing a proactive approach to replacement can help avoid unexpected failures and disruptions within the piping system.

In conclusion, proper handling, regular maintenance, and adherence to manufacturer guidelines are essential for ensuring the reliability and longevity of rubber joints in industrial applications. By following best practices and implementing a comprehensive maintenance strategy, operators can optimize the performance of rubber joints and minimize the risk of premature failure within their piping systems.