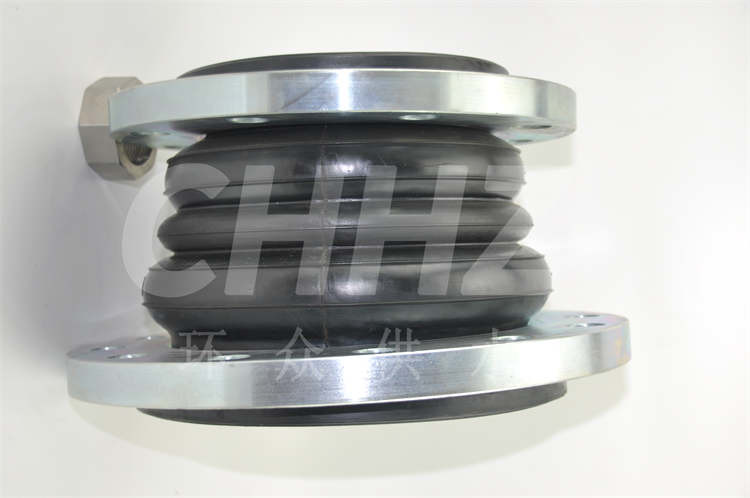

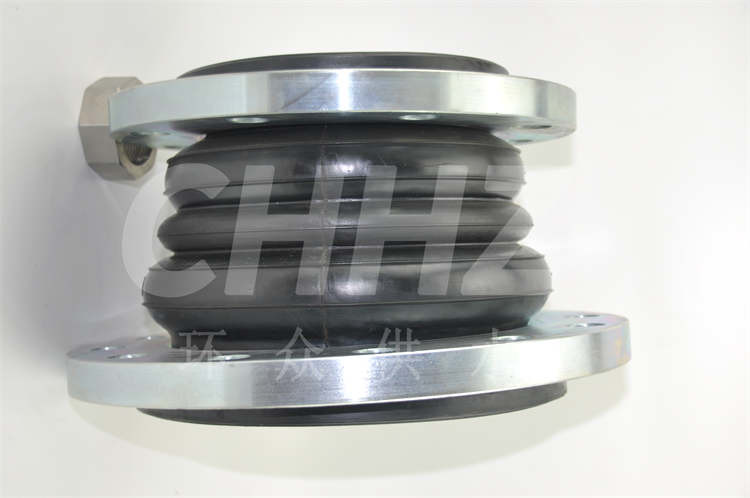

Requirements for Rubber Expansion Joints in Piping Systems

Rubber expansion joints play a crucial role in accommodating movement, absorbing vibration, and mitigating stress in piping systems. To ensure optimal performance and longevity, certain fundamental requirements must be considered when selecting and installing rubber expansion joints in various fluid handling applications.

First and foremost, one of the key requirements for rubber expansion joints is compatibility with the media being conveyed within the piping system. It is imperative to assess the chemical composition, temperature, and concentration of the fluids to which the expansion joints will be exposed. By selecting rubber materials that are resistant to the specific chemicals and operating temperatures, the risk of degradation, swelling, or loss of mechanical properties can be minimized, prolonging the service life of the expansion joints.

Additionally, the design and selection of rubber expansion joints should consider the operational pressures and vacuum conditions inherent in the piping system. It is essential to verify that the expansion joints have sufficient pressure ratings and vacuum stability to withstand the internal pressure and external forces exerted on the system, preventing premature failure and leakage.

Another critical requirement for rubber expansion joints pertains to their ability to accommodate various types of movement and displacement. Whether dealing with axial, lateral, or angular movement, the expansion joints must be capable of flexing and extending without overstressing or reaching their limits. Proper consideration of movement capabilities and dimensional requirements ensures that the expansion joints effectively isolate vibration and compensate for thermal expansion and contraction without inducing excessive strain on the piping system.

Furthermore, the installation and anchoring of rubber expansion joints are essential aspects that contribute to their effective performance. Adequate anchorage and support mechanisms should be employed to secure the expansion joints and prevent overstressing due to deadweight, pressure thrust, or external forces. Additionally, the orientation and alignment of the expansion joints within the piping system must be carefully executed to facilitate unrestricted movement and prevent binding or misalignment during operation.

Temperature compatibility is another vital requirement for rubber expansion joints, especially in applications with extreme temperature variations. Selecting elastomeric materials that maintain their resilience and mechanical properties within the specified temperature range ensures the integrity and functionality of expansion joints under diverse thermal conditions, safeguarding against deformation, stiffness, or thermal degradation.

Moreover, the compliance with industry standards, such as those outlined by organizations like the Rubber Expansion Joint Division of the Fluid Sealing Association (FSA), and adherence to recognized quality and performance certifications are essential requirements for ensuring the reliability and suitability of rubber expansion joints in piping systems. Conforming to established standards and specifications provides assurance of product quality, material consistency, and dimensional accuracy, contributing to the integrity and performance of the expansion joints.

In conclusion, considering these fundamental requirements, such as chemical compatibility, pressure ratings, movement capabilities, installation practices, temperature resistance, and compliance with industry standards, is critical for the successful application of rubber expansion joints in piping systems. By meticulously addressing these requirements, engineers, specifiers, and end-users can optimize the functionality, reliability, and durability of rubber expansion joints, promoting the efficient operation and longevity of fluid handling systems.