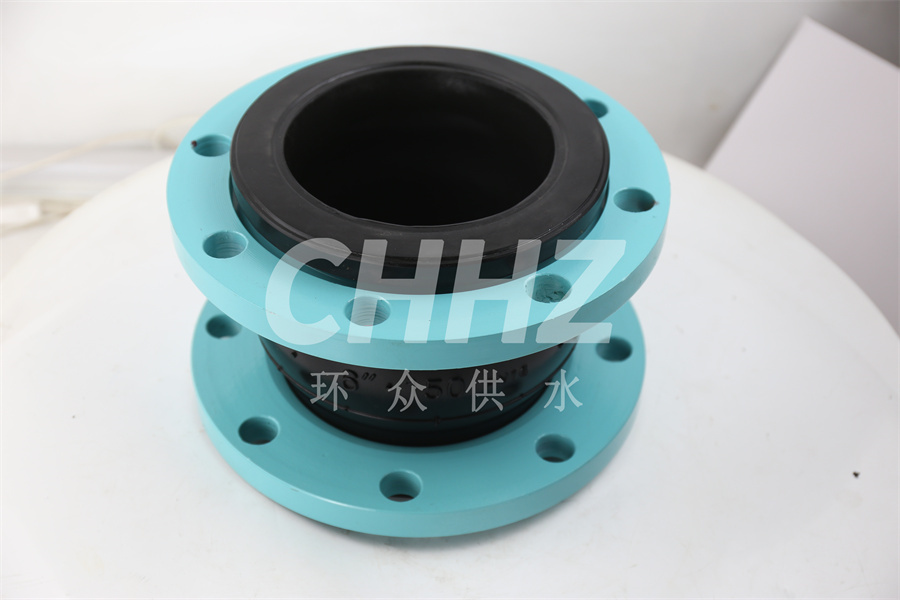

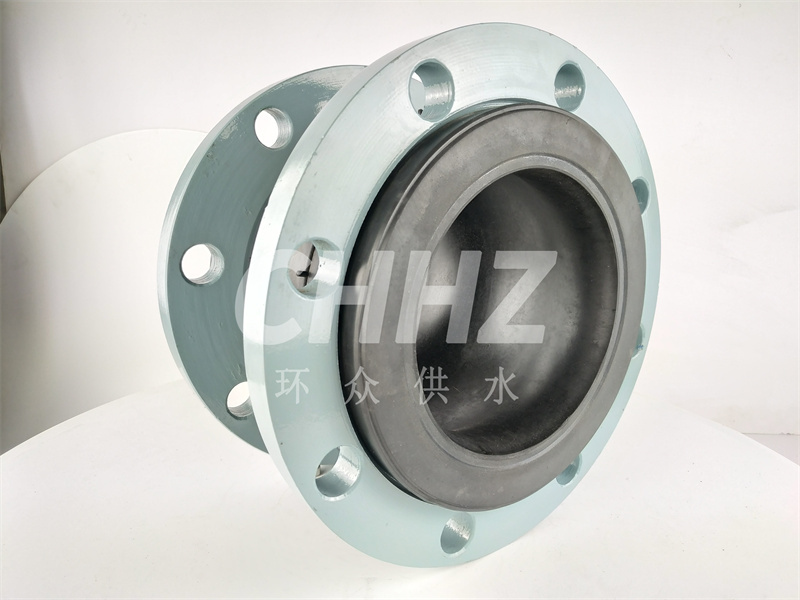

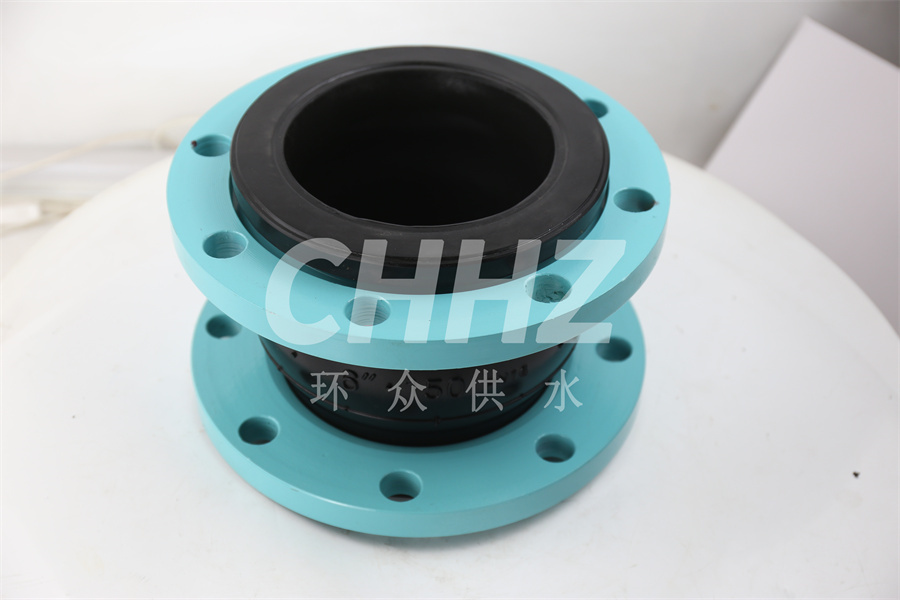

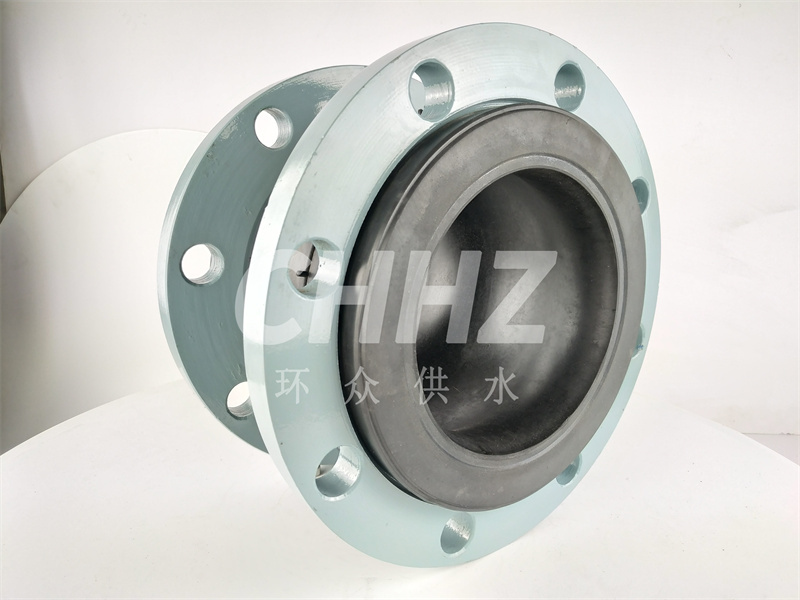

Use and installation of flange connection flexible rubber joints.

The application of bendable rubber joints is becoming more and more common, then the use of the whole process of assembly is a very important whole process, assembly is not good, the application of the course of the pipeline is not beneficial, but very easy to cause pressure, before the installation and use to check its type specifications, specifications and pipeline equipped with the status, be sure to meet the design provisions. In the assembly process, the welding seam shall not spill onto the surface of the wave shell, and the wave shell shall not be damaged by other mechanical equipment. Flexible rubber joints are generally suitable for transport pipelines in the fields of urban heating, metallurgical industry, mining, power generation, petrochemical equipment, engineering construction, etc. It is suitable for transporting sea, talk water, cold and hot water, domestic water, domestic sewage treatment, oil, gas and diesel, gas, liquefied gas and other substances.

Installation of flange connection bendable rubber joint

1. The rubber soft joint is made of itself. Seal ring. Card fastening prefabricated components composed of connecting pipeline machinery and equipment. The payout RF connector is used to absorb the digestive deflection, and can not bear the driving force. Single tab rubber soft connector is made of prefabricated components, such as rubber soft connector and reducer tee. It can prevent system vulnerability or destruction of the payout RF connector caused by excessive pipeline deflection. Importantly, it is suitable for absorbing and digesting tangential deflection and carrying capacity pushing force of pipeline coupling within the scope of allowable deflection.

Applicable and flange connection, and at the same time with the pipeline connection. In the assembly process, adjust the installation length of both sides and the pipeline or flange, the angle symmetry on the tight single-flow valve ground screw, and then adjust the nut so that the pipeline can expand and contract at will, lock the amount of expansion and contraction, and ensure the reliable operation of the pipeline. Flange rubber soft joint is made of itself. Seal ring. Card fastening prefabricated components composed of connecting pipeline machinery and equipment. The payout RF connector is used to absorb the digestive deflection, and can not bear the driving force.

Flange connection using carbon steel flanges, mainly in accordance with the requirements of customers to match. Carbon steel butt weld flange has the characteristics of not easy to deformation, good sealing, wide application, suitable for pressure or temperature fluctuation of the pipeline or high temperature, high pressure and low temperature pipeline. Advantages are cheaper, heat-resistant function, carbon steel flange surface need to be pickled spraying treatment, forging flange surface without pores, flange surface flat, very suitable for the use of surface using hot dip galvanizing treatment, namely hot dip zinc, to achieve anti-corrosion effect, hot dip galvanized flange rubber joint long service life, reliable quality.