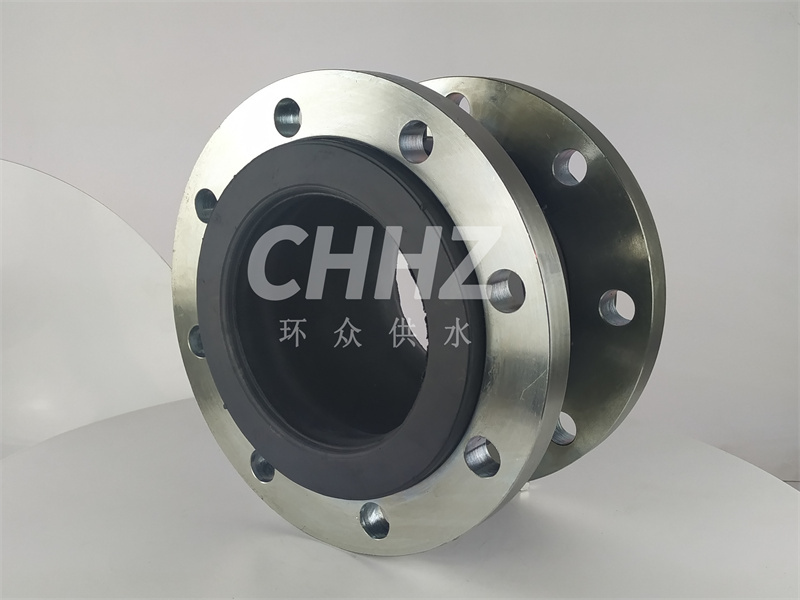

Seven advantages of using EPDM rubber expansion joints

EPDM rubber expansion joint can reduce the working pressure driving force and compensate the pipeline installation deviation, can not digest and absorb the radial deviation. Mainly used in the pump, gate valve and other accessories coupling. Different major uses use different materials basic construction pipeline's total length varies, the amount of pipeline collection and discharge varies, so the joint of the pipeline should be installed at the joint of the pipeline joint related goods, it can not only transmit the connected parts of the working pressure driving force compensation pipeline deviation, but also maintain the pipeline .

1、Excellent aging resistance performance. This is one of the significant features of EPDM rubber, its aging resistance is not only much better than the butyl rubber (SBR), natural rubber (NR), neoprene (Neoprene) and other common rubber, but also better than the generally considered good aging resistance butyl rubber.

2, chemical stability is better. In the EPDM (EPDM) rubber used in the process of long exposure to a variety of characteristics of chemicals, its performance changes are small. And other ordinary rubber in contact with a variety of characteristics of chemical-

3, drugs, will significantly accelerate the process of its aging failure.

3, has excellent resistance to compression deformation and compression stress relaxation performance. EPDM (EPDM) rubber compression deformation is very small, stress relaxation is particularly slow, its compression deformation resistance is also better than other ordinary rubber.

4, has a high elasticity. In general rubber its elasticity is second only to natural rubber (NR) and cis-polybutadiene rubber, higher than other ordinary rubber.

5, high temperature resistance: EPDM rubber expansion joints can be used for a long time at 120 ℃, and can be used briefly or intermittently at 150- 200 ℃. It has excellent water vapor resistance and is estimated to be better than its heat resistance.

6, corrosion resistance: due to the lack of characteristics of ethylene propylene rubber (EPR) in EPDM rubber joints, low unsaturation, so it has good resistance to various characteristic chemicals such as alcohols, acids, alkalis, oxidizers, refrigerants, detergents, animal and vegetable oils, ketones and greases.

7、Have good elasticity: EPDM rubber expansion joints have better elasticity than natural rubber joints.

EPDM rubber expansion joints are easy and fast to install and operate, convenient for gate valve installation, and can bear the radial tensile force of the pipeline. The metal material is cast or welded to form a trapezoidal rubber sealing ring. The basic principle of rubber shrinking elastic deformation is under the action of rotating cover and foot bolt. Filler seal in the middle of the expansion pipe surface of the connector itself. Performance indicators and customer regulations are used. Material outside the spraying high toughness anti-corrosion paint, connecting the foot bolt for high toughness alloy steel or stainless steel. Easy installation and operation, convenient gate valve installation, can bear the radial tensile force of the pipeline. The metal material is cast or welded to form a trapezoidal rubber sealing ring. The basic principle of rubber narrowing elastic deformation is under the action of rotating cover and foot bolt. Packing seal in the middle of the expansion pipe surface of the connector itself.