What is the structure of metal hose?

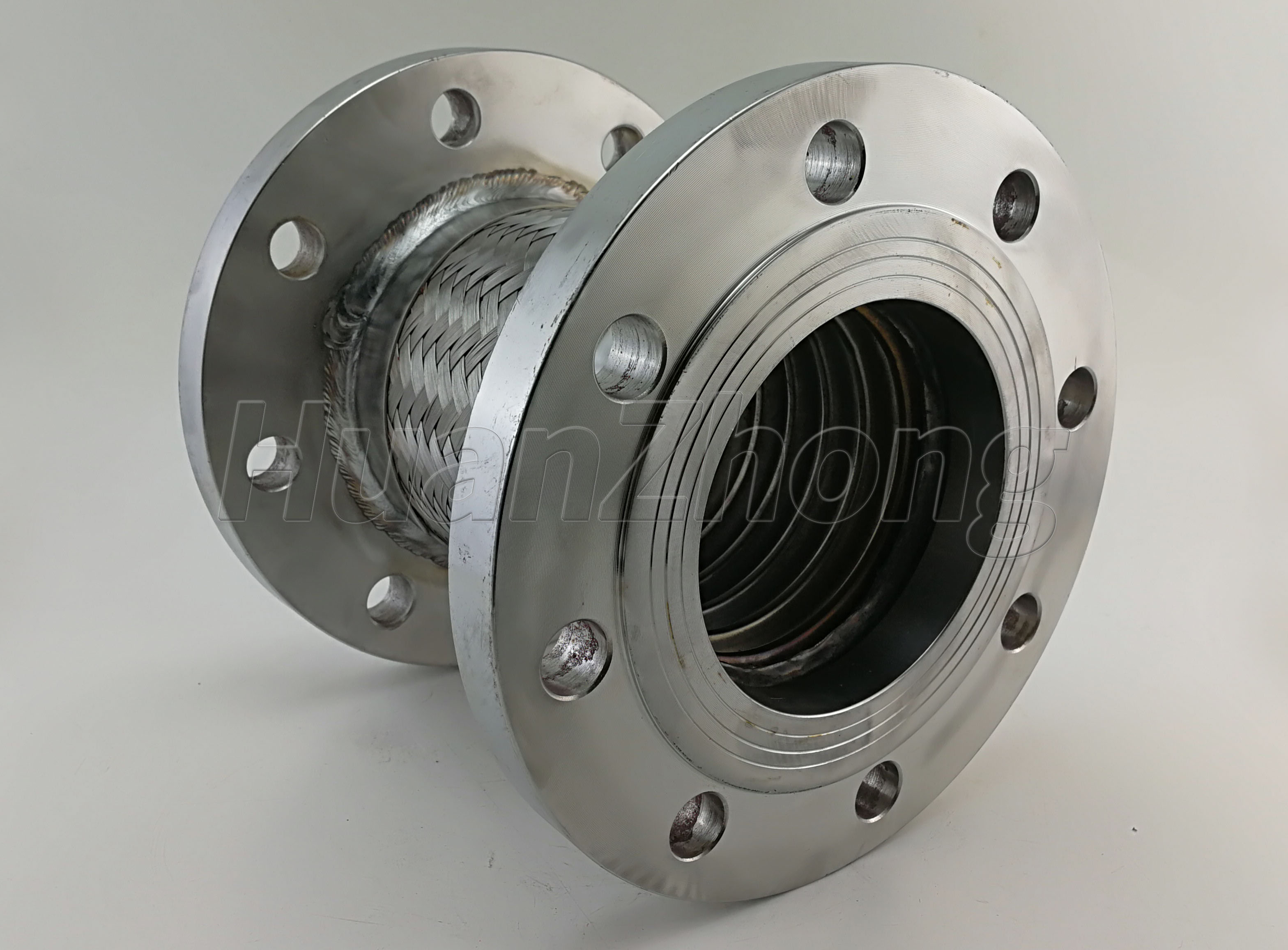

The metal hose is largely composed of bellows, mesh sleeve and joint. The bellows is the body of the metal hose, playing the role of flexibility; the mesh sleeve plays a strengthening, shielding role; the joint plays the role of connection. For different use requirements, they are connected with each other in different ways: bellows, mesh sleeve and joint three parts to weld the form of connection, called welding type; to mechanical clamping form of connection, called mechanical clamping type, in addition, there are the above two methods used in combination, called mixed type.

Metal hose products include oil hose, steam hose, sand blasting hose, acid and alkali hose, food hose, oxygen blowing hose and all kinds of shaped hoses. They are widely used in machinery, chemical industry, petroleum, metallurgy, food and other industries.

What is the pressure range of pressure-resistant metal hose: the pressure range of the hose is generally PN0.6-32.0Mpa. up to 42.0MPa. Metal hose is the main pressure-bearing parts of the hose installed in the pressure pipeline, while the bellows plays the role of sheathing, according to the size of the pressure in the pipeline and the application site, you can choose one or more layers of stainless steel wire or steel belt for Weaving.