How to distinguish between real and fake corrosion resistant rubber joints?

Previously, we introduced rubber joints and corrosion resistant rubber joints. But there are still a lot of people in our daily life who can't fight to distinguish corrosion resistance, so how exactly should corrosion resistant rubber joints be distinguished?

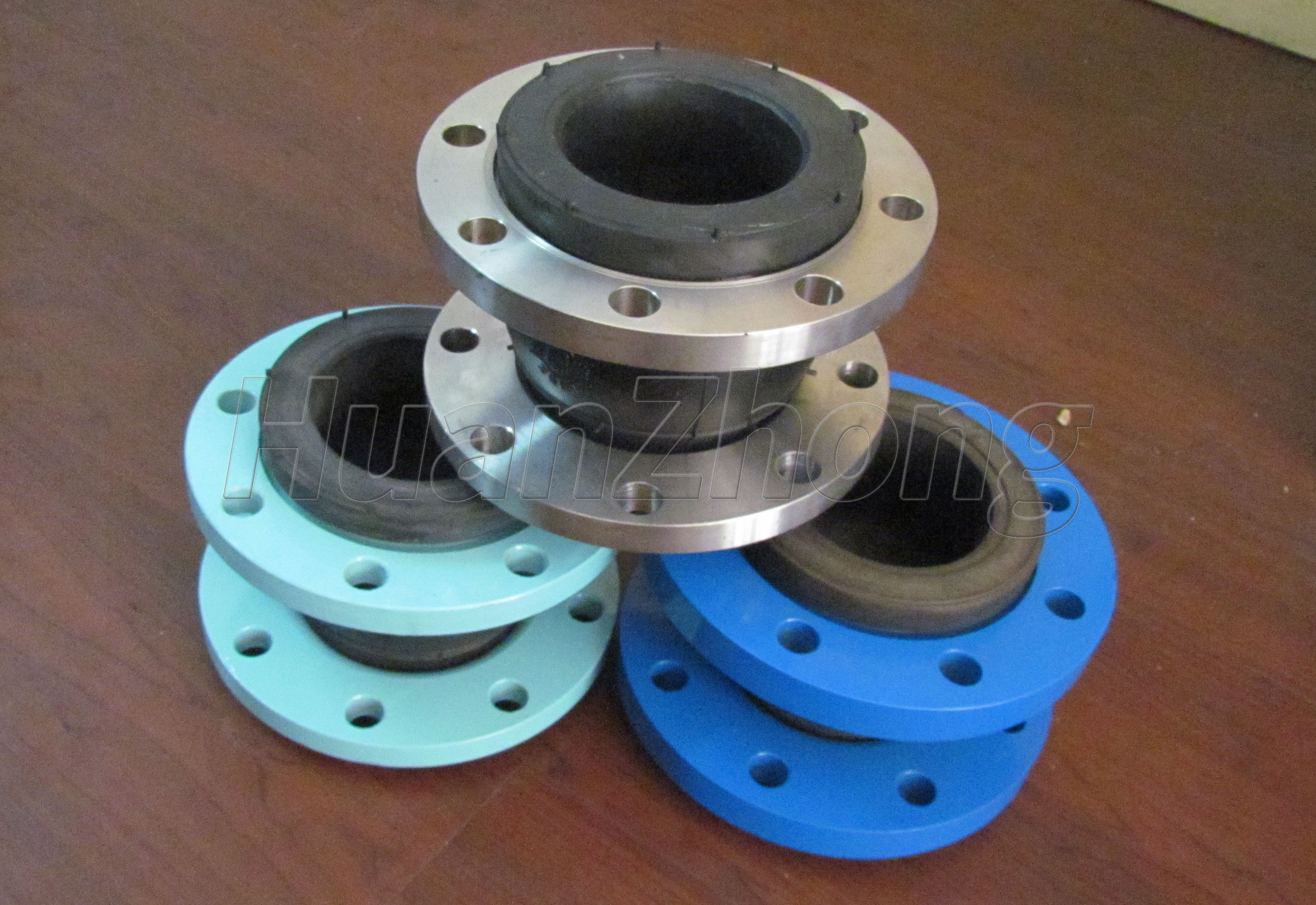

EPDM rubber joints are also called rubber hose flexible joints, flexible EPDM rubber joints, rubber flexible joints, bendable EPDM rubber joints, high pressure EPDM rubber joints, rubber shock absorbers, expansion joints and so on. According to the connection method, it is divided into three types: loose flange type, fixed flange type and threaded type; according to the structure, it can be divided into five types: single sphere, double sphere, reducer, curved sphere and wind pressure coil.

The rubber joint consists of inner and outer layer of rubber, cord fabric layer and steel wire ring, which is formed by vulcanization and then loosely combined with metal flange or parallel joint. This product can reduce vibration and noise, and can compensate for thermal expansion and contraction caused by temperature changes, and is widely used in various pipeline systems. It is made by high pressure and high temperature mold vulcanization.

Features: high internal density, can withstand high pressure, good elastic deformation effect.

Advantages: EPDM rubber joints reduce vibration, reduce noise, good expansion and contraction, easy to use.

Application: connection with pumps and valves, fire-fighting equipment, pipelines with high vibration, pipelines with frequent changes of heat and cold.

Applicable media: seawater, fresh water, hot and cold water, drinking water, domestic sewage, crude oil, fuel oil, lubricating oil, refined oil, air, gas, steam and granular powder.