Construction standards for expansion joints

According to the construction specifications for industrial metal piping projects, the installation of expansion joints should be carried out in accordance with the provisions of the construction: once burst may produce significant losses of people and property, resulting in catastrophic effects.

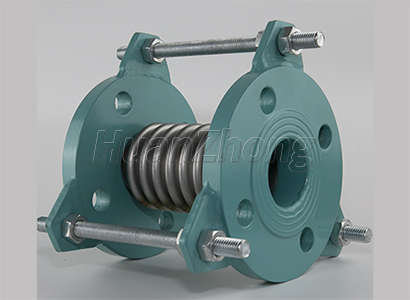

1 . When installing the expansion joint, no temporary support pieces shall be welded on the wave joint, and when lifting, no sling shall be tied to the wave joint.

2 . When installing the expansion joint, its straight pipe length shall not be less than 100mm.

3 . Bracket and hanger installation

The main advantage of the corrugated expansion joint is that it can compensate for three-way displacement (axial, radial, angular), and the corrugated expansion joint is leak-free and maintenance-free during its service life. The fixed bracket of the pipe is set up to ensure reasonable distribution of the thermal expansion of the pipe between the compensators, and when the temperature change causes expansion or contraction of the pipe, the fixed bracket can prevent the displacement of the pipe at that point. With the compensation device supporting the fixed bracket should be fixed before pre-stretching (compression), in order to make the expansion joint compensation device to play its due role. Only one fixed bracket can be installed on the straight pipe section with displacement without compensation device, otherwise it will hinder the displacement.

Corrugated expansion joint material requirements are important: the appearance of metal materials and other defects metal materials; check the specifications of the steel plate, steel number and other technical conditions, and material conformity certificate.