What is an oil-resistant rubber joint? What are the advantages?

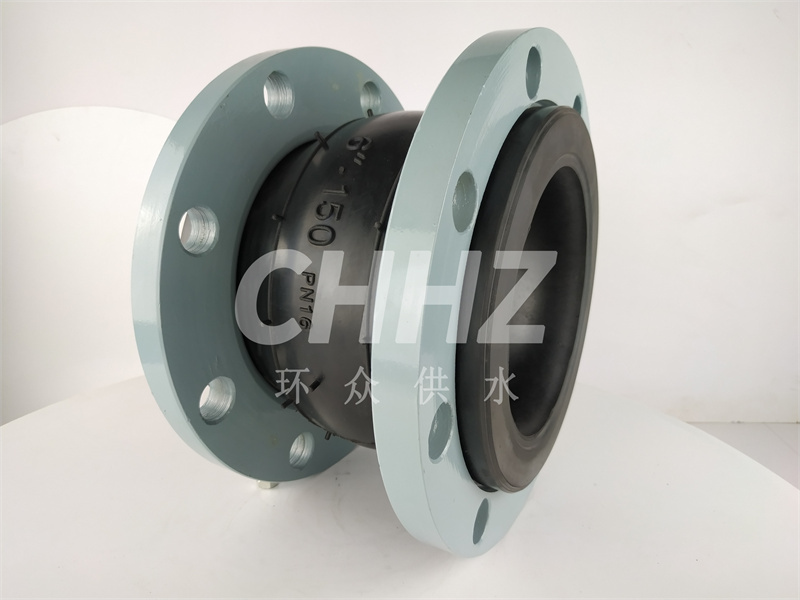

Oil resistant rubber soft coupling is a kind of pipeline joint with high elasticity, high air tightness, medium resistance and weather resistance. It is divided into: concentric equidistant, concentric reducer, eccentric reducer according to the shape. According to the structure: single sphere, double sphere, elbow sphere. According to the connection form: flange connection, threaded connection, threaded pipe flange connection. Divided by working pressure: 0.25MPa, 0.6MPa, 1.0MPa, 1.6MPa, 2.5MPa five grades. Made of special rubber with good oil resistance and weather resistance, the skeleton material is made of high-strength copper-plated steel wire, special structure design and special equipment production, with the characteristics of high pressure-bearing and small deformation of the pressurized volume, the use of full reliability.

Oil-resistant rubber joint sphere is composed of inner rubber layer, reinforcement layer with multi-layer scraping nylon cord fabric, outer rubber layer compound rubber tube. Nitrile rubber (NBR) Copolymer of butadiene and acrylic. Features are particularly good resistance to gasoline and aliphatic hydrocarbon oils, second only to polysulfide rubber, acrylate and fluorine rubber, and better than other general-purpose rubber. It has good heat resistance, good air tightness, wear resistance and water resistance, and strong adhesion.

Nitrile oil resistant rubber joint is a hollow rubber product used for flexible connection between metal pipes. It is composed of inner and outer rubber layers, cord fabric layer and steel wire ring, which are formed by vulcanization and then loosely combined with metal flange or parallel joint. This product can reduce vibration and noise, and can compensate for the thermal expansion and contraction caused by temperature changes, and is widely used in various piping systems. It also improves the life and quality of flexible joints used in hydraulic oil, petroleum, oil, diesel, lubricating oil and other environments. It avoids the trouble of frequent replacement of rubber joints that are prone to cracking and corrosion in the oil condition.