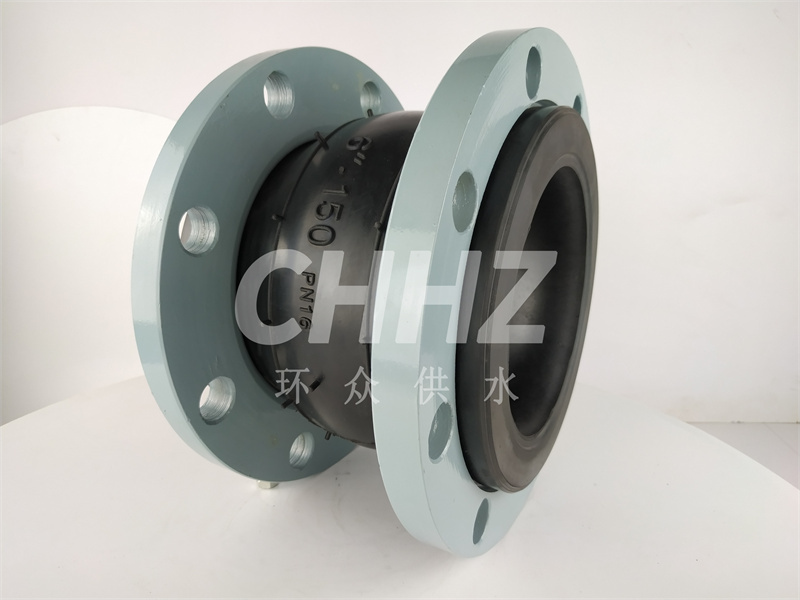

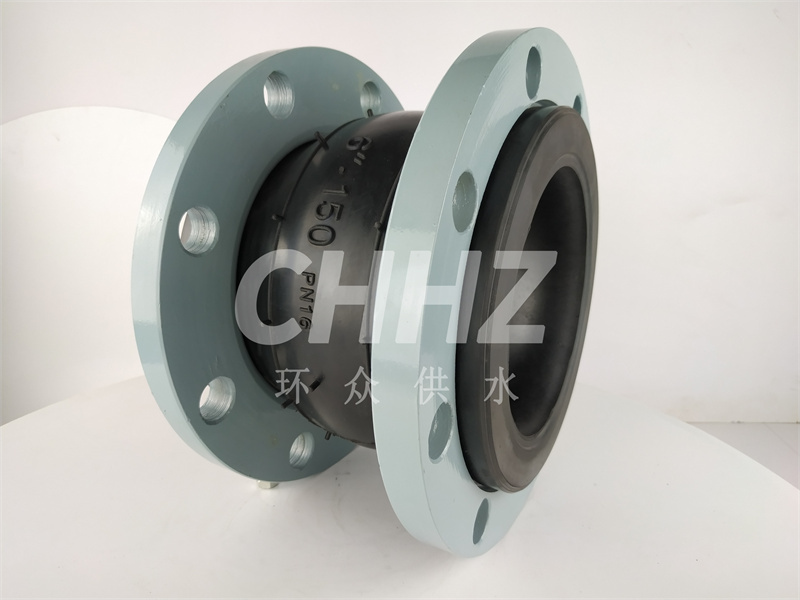

The advantages of standard rubber joints.

Rubber joints are widely used in pipeline connections and have high demand for circulating media. National standard rubber soft joints are highly adaptable to a variety of media.

National standard rubber joints have good repetitive displacement (change) reducibility and can provide large directional compensation in a small size range, which can better eliminate the multi-directional errors arising from the installation of various pipeline connections.

Do not use defective national standard rubber joints for installation. National standard rubber joints can be used for lifting and conveying raw water and sewage, feed water and circulating water of thermal power plants, metallurgical industry, condensate, pipeline transportation of chemical substances in chemical industry, petrochemical industry, dilution and connection between long and short distance pipelines in other industries. Because rubber has high abrasion resistance, it is also suitable for low-temperature transportation of granular and powder and gas in all industries. When the pipeline medium is more special, special rubber is needed to cope with it. Such as oil resistant national standard rubber joints, acid and alkali resistant national standard rubber joints, etc.

The national standard rubber joint strictly stipulates the flange outer diameter, diameter, bolt aperture, flange thickness, bolt thickness, bolt number and other data, and specifies the data in detail, so that the flange of the rubber joint can have high quality tensile performance. Do not use defective national standard rubber soft joints when installing national standard rubber soft joints, and carefully check the exterior and interior of national standard rubber soft joints. When the pipeline medium is special, special rubber is needed to cope with it. Such as oil resistant national standard rubber soft joints, acid and alkali resistant national standard rubber soft joints, etc.. The flange of the connection needs to be strictly enforced according to the national standard. When the reinforcement limit is needed, each bolt needs to be checked so that the tightness of all the bolts is consistent. The material used in rubber joints is generally imported rubber, which is divided into butyl rubber, neoprene, EPDM rubber, silicone rubber, fluorine rubber, etc. The material standard requirements for rubber joints are very strict, starting from procurement, inspection, storage and other aspects of the origin. For each link, the production activities should be carried out in accordance with the requirements of the rubber products industry and its own production characteristics, so the material is qualified to meet the requirements of good raw materials is the key to manufacturing rubber joints.