How can rubber joints be perfectly installed?

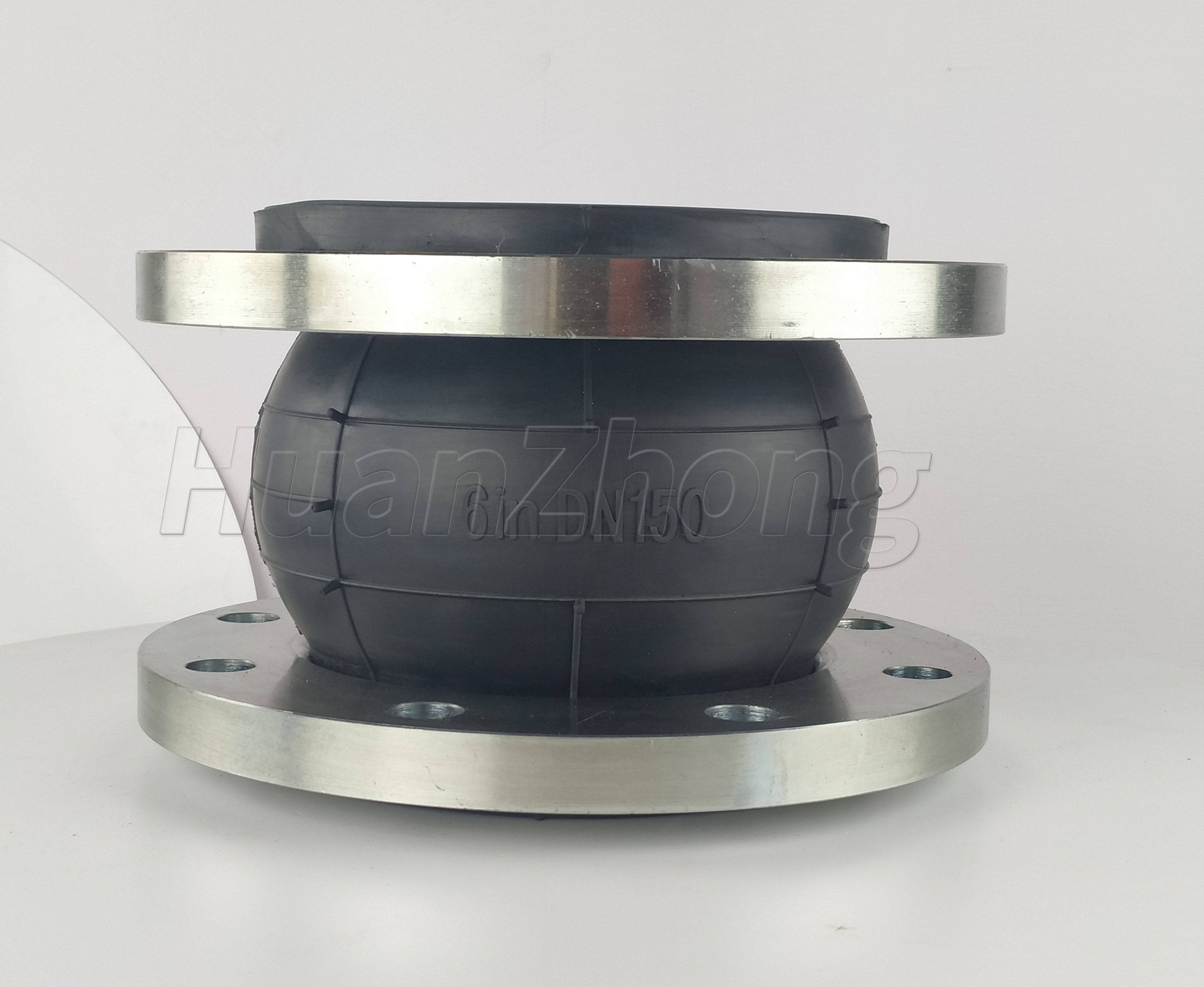

Rubber joints are recognized by consumers because of the high quality compressive strength tensile properties of the software itself. Along with the continuous improvement of standards in the pipeline field, the installation and operation of rubber joints looks crucial, under the condition of ensuring the quality of the product, according to the extreme installation of rubber joints can make rubber joints in the pipeline its own offset compensation characteristics in many ways to give full play, as a technical professional rubber joint manufacturer, today I will describe in detail how to ensure the perfect installation of rubber joints.

How can rubber joints be perfectly installed?

1. When installing single socket flex rubber joints in the pipeline, it is important to let them be in a natural situation, so that there is no need for artificial factors to make the goods deformation. When the pipeline material is corrosion-resistant. Oil. High temperature and other materials should be taken higher than the pipeline pressure a stop connection head.

2. The flange for connecting rubber joints should be flat-welded flange with neck or flange in accordance with GB/T9115.1-2000.

3. All normal available materials for flexible rubber joints are ordinary water with temperature of 0-80C. In the case of unique substances such as oil, strong acid, strong alkali, high temperature, corrosion and hard materials, special resistant raw material rubber joints obtained by relative labor should be used, not blindly following the trend or general use.

4. When flexible rubber flexible joints are used in the import and export trade of centrifugal pumps, they should be located on one side of the water spring, and the metal material reducer joints should be installed in the middle of the water spring and in the large diameter source of the size head.

5. When the pipeline offset is higher than or equal to the large compensation of the connector, the total number of connectors should be elevated to parallel surface offset, and it is prohibited to become the deviation of the adjustment pipeline, so that even the connector at the upper limit of the tensile strain offset and road conditions, more super degree offset, expansion and contraction, etc.

6. High-rise residential heating pipeline or hanging in the air to drainage, pipeline should be fixed immobile in the bracket. Fixed bracket or anchor frame, cut can not let the connection head bear the net weight of the pipeline itself and axial force, or the connection head should be configured to prevent pull-off equipment.

7. In the installation of rubber joints, the bolts of the ground bolts should be extended to both sides of the connection head, each flange connection ground bolts in accordance with the angle of each flange constantly and evenly twisted to avoid pressure deviation. To use the standard wrench to twist evenly, do not use the drive rod to move sideways to make the joint slip, to have slippery edges and fractures, and to carry out regular maintenance to prevent loosening, falling off and leakage.

8. After the rubber soft joint bears the force for the first time or before starting up again after long-term stop using, the foot bolt should be charged and torqued again in the funds to put into operation.

9. Application or storage of rubber soft joints should be prevented from high temperature, ozone oil and strong acid and alkali natural environment. The pipeline used outdoors or facing the wind at sunrise should be built to shade the frame and prohibit sun screen. Rain. Wind turbulence. It is forbidden to paint and wind insulation materials on the surface of the joint. If the problem of embrittlement occurs due to rubber products, it should be tested and removed immediately.