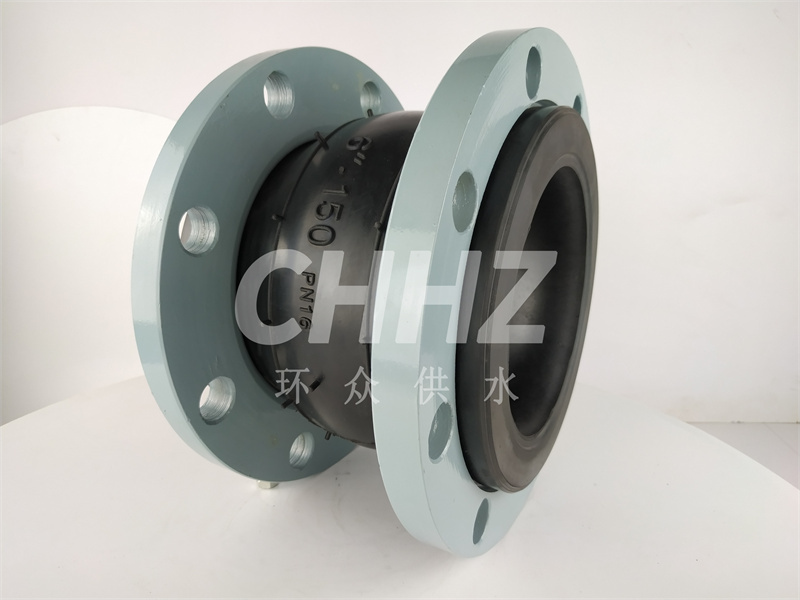

Flexible rubber expansion joint

A rubber expansion joint is an equipment component that is installed on a pipe. Although it is mainly used to reduce vibration and noise, it may cause serious consequences such as water leakage problems, pull-out problems, water immersion deformation and dimensional deformation if it is not properly installed or used in a standardized way. Leakage: Most leaks are caused by improper installation. When installing, tightening the screws is a process that must be paid attention to. The method of diagonal tightening cannot be changed, otherwise the local seal is not sufficient. The situation, which in turn leads to the occurrence of rubber soft joint leaks. Traction situation: This situation is because the actual extension of the installed pipeline exceeds the limit extension length of the rubber joint, resulting in the flange being forcibly pulled out of both ends of the sphere. When you encounter this situation, please replace it in time. You can use double sphere rubber soft joints, or you can add a limiting device inside the rubber joint to use. The limit device has a certain specification for the stretching of the rubber joint.

Product features: The product consists of inner and outer layers of rubber, cord fabric layer and steel wire ring, which are formed into tubular rubber parts by high temperature and pressure, and then loosely combined with metal flanges or parallel joints. This product takes advantage of high elasticity, high gas performance, medium resistance, weather resistance and radiation resistance of rubber, which can reduce vibration and noise and compensate for thermal expansion and contraction caused by temperature changes. It is widely used in various piping systems. Vibration damping, noise reduction, good airtightness and flexibility, easy to use. High internal density, can withstand high pressure and good elastic deformation effect.

Submersible sewage pump is a new generation of pump products successfully developed on the basis of the introduction of advanced foreign technology, combined with the use of built-in pumps. It has remarkable energy-saving effect, spinning winding, non-clogging, automatic installation and automatic control. Wait. View. With the role of discharging solid particles and long fiber waste. Product pump adopts . Impeller structure and new mechanical seal, which can effectively convey solids and long fibers. Compared with the traditional impeller, the impeller of this pump adopts the form of single channel or double channel, similar to the elbow, with the same cross-sectional size and has very good flowability. Equipped with reasonable worm shell, the pump is highly efficient High and impeller are tested by dynamic and static balance, so that the pump runs without vibration and low noise.