Advantages of installing steel wire rubber expansion joints for water pump inlet and outlet.

Rubber joints are one of the common pipeline connection fittings. Rubber joints play a big role in pipeline installation, and we can often see them in the pipeline installation. It has a certain degree of elasticity and connects pipes without being affected by medium fluctuations, so it can be used in many places. Because it has good wear resistance, it can be used in many places. Rubber joints are more and more widely used in the construction industry, so in many professional fields, do rubber joints have its unique and advantages? Let's learn more about it.

It is widely used in various fields, for example, in petroleum, chemical, metallurgy, electric power, construction and other industries, if there are pipeline connections in these industries, there will be rubber joints, which can protect the pipeline very well. In the petroleum industry, rubber joint is also a good product. It can protect oil pipelines and pipes very well. In metallurgical industry, rubber joints can protect not only steel equipment but also equipment. And in the electric power industry, rubber joints can protect the electric power equipment very well. In addition, because rubber joints can withstand higher pressure and higher temperature, it can be used under a variety of temperature and pressure conditions. In the construction industry, rubber joints can also be used in thermal compensation systems.

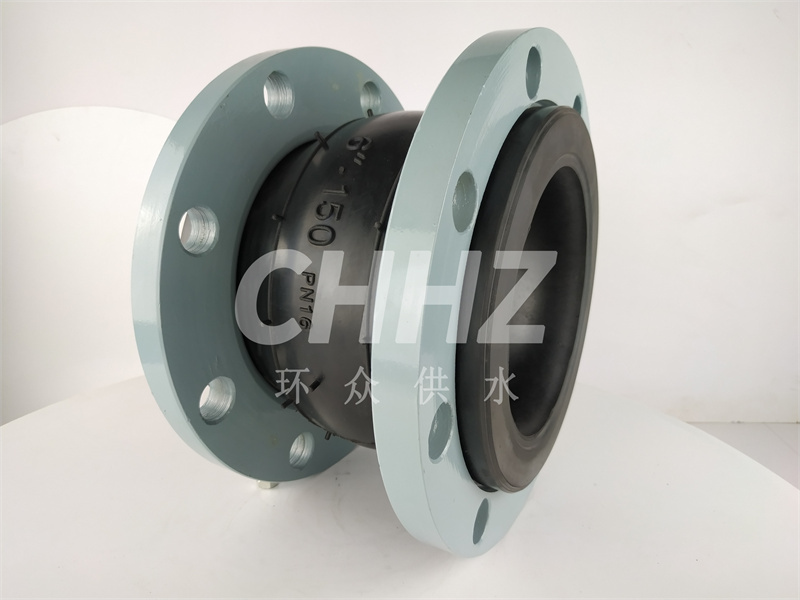

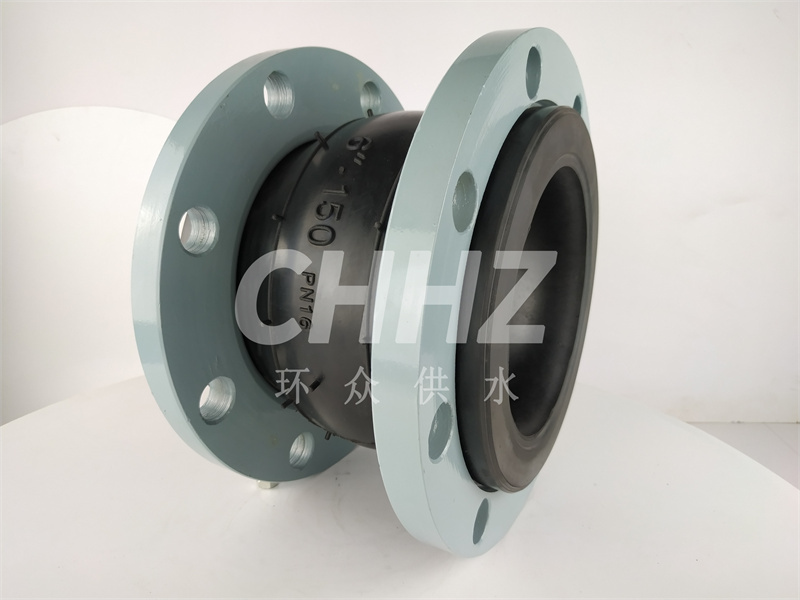

Water pump out is convenient for disassembling and installing valves as well as maintenance needs; the actual installation order should be: rubber flexible joint, check valve, gate valve. The pressure gauge is best installed on the water pump outlet, but must be in front of the check valve. When working normally, the gate valve is not much operated, while the check valve is frequently operated, so the probability of maintenance is higher, and the maintenance can be repaired without affecting the normal operation of the system by closing the gate valve of the pump outlet. Pressure gauge installed in front of the check valve can prevent the impact and damage of water hammer action on the pressure gauge. Rubber joints cannot be directly connected with metal pipes or equipment If the interface of metal pipes and rubber joints are together, it will affect the sealing effect of the joints. Welding should be done according to the design requirements before use. Rubber joints can be connected directly with metal pipe fittings through flanges when flanges are set in the inner cavity. Care must be taken not to set flanges inside the flange, as this will affect the sealing effect and reduce the service life. Rubber joints have a relatively long service life Rubber joints are made up of two parts. The external rubber component is made of corrosion-resistant synthetic rubber. It has high corrosion resistance and good vibration damping.