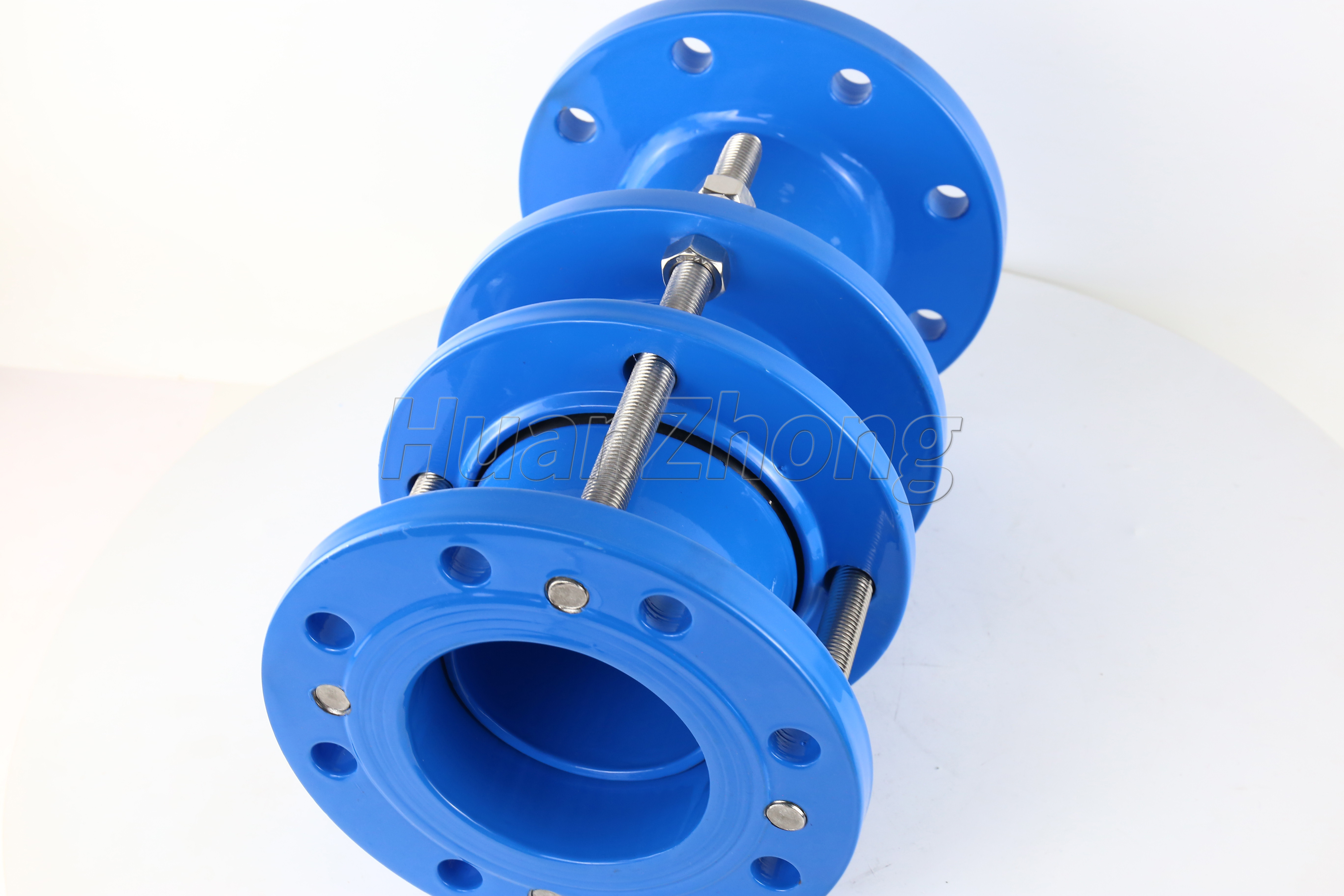

Double flange limit expansion joint with complete specifications and stable performance

In the double flange limit expansion joint, chromium is the element that strongly forms and stabilizes the iron body and narrows the austenite zone. In this regard, the commonly used double flange limit expansion joint is the one with the appropriate ratio of chromium and nickel.

As mentioned before, the precipitation of σ, χ phase not only significantly reduces the plasticity and toughness of the joint, but also reduces the corrosion resistance of the joint under some conditions. Therefore, it is difficult to obtain martensitic organization for high chromium (e.g. more than 20%) double flange limit expansion joints even after cold working and low temperature treatment.

The factor that has a great influence on the sensitivity of double flange limit expansion joint pipeline is the carbon content in double flange limit expansion joint. The effect of other elements on the pipeline depends mainly on their effect on the dissolution and precipitation behavior of carbide, in double flange limit expansion joint, chromium can reduce the solubility of carbon and depletion of chromium, thus increasing the chromium content is beneficial to the resistance of double flange limit expansion joint to pipeline corrosion.

Chromium is very effective in improving the resistance to pitting corrosion and crevice corrosion of double flange limit expansion joints. This effectiveness of chromium is greatly enhanced when molybdenum or molybdenum and nitrogen are present in the double flange limit expansion joints. Molybdenum and nitrogen resistance to pitting and crevice corrosion will be lost or not significant enough.