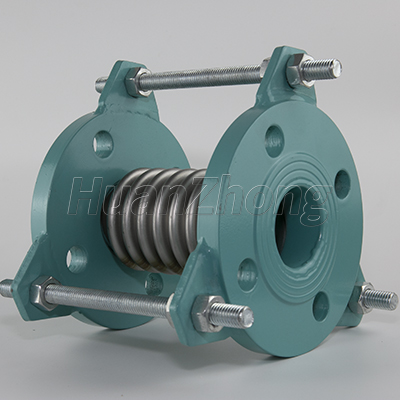

Corrugated expansion joint to meet the standard needs to meet the requirements

Oil immersion device for corrugated expansion joint, including corrugated expansion joint, corrugated expansion joint placing frame and base, said corrugated expansion joint and corrugated expansion joint placing frame are set side by side on the base, one end of the corrugated expansion joint is set with tube and second tube respectively, the bottom of the corrugated expansion joint is provided with three tubes, oil pump, paper tape filter and second oil pump are connected between the tube and third tube in turn, the end of the second tube is connected with water pump and water collection tank in turn.

It solves the technical problem that the descaling oil cannot be completely recovered or the recovery effect of descaling oil is poor in the existing technology. Process hardening occurs in the corrugated expansion joint. During the cold drawing process, the metal undergoes welding deformation. There are many slip systems in the crystal and dislocation movements intercept each other. Many dislocations are welded, leading to dislocation accumulation and dislocation source arrest. These processes lead to a decrease in dislocation mobility and an increase in dislocation density.

When further weld deformation occurs, the stress increases enough to cause the weld dislocations to start moving, the weld dislocations cross-slip, and the edge dislocations cannot cross-slip. As a result, dislocation intersection occurs and the number of fixed orders increases. The presence of residual compressive stresses on the surface facilitates the closure of surface cracks and hinders erosion expansion. As a result, the surface corrosion resistance of corrugated expansion joints increases, the generation of fatigue cracks is delayed, and the fatigue strength of corrugated expansion joints increases.

By roll forming, a cold hardening layer is formed on the rolled surface, which reduces the elastic welding deformation of the corrugated expansion joint, improves the wear resistance of the inner wall of the corrugated expansion joint, and avoids grinding burns. After welding, the surface roughness is reduced and the matching performance is improved. The corrugated expansion joint is mainly in the inner hole, the outer wall size tolerance and roughness is strict and high precision. As the test temperature decreases, the cold brittle alloy steel with body-centered cubic lattice will change from ductile fracture to brittle fracture. Embrittlement of corrugated expansion joints occurs in the temperature range from room temperature to below zero, called cold embrittlement.