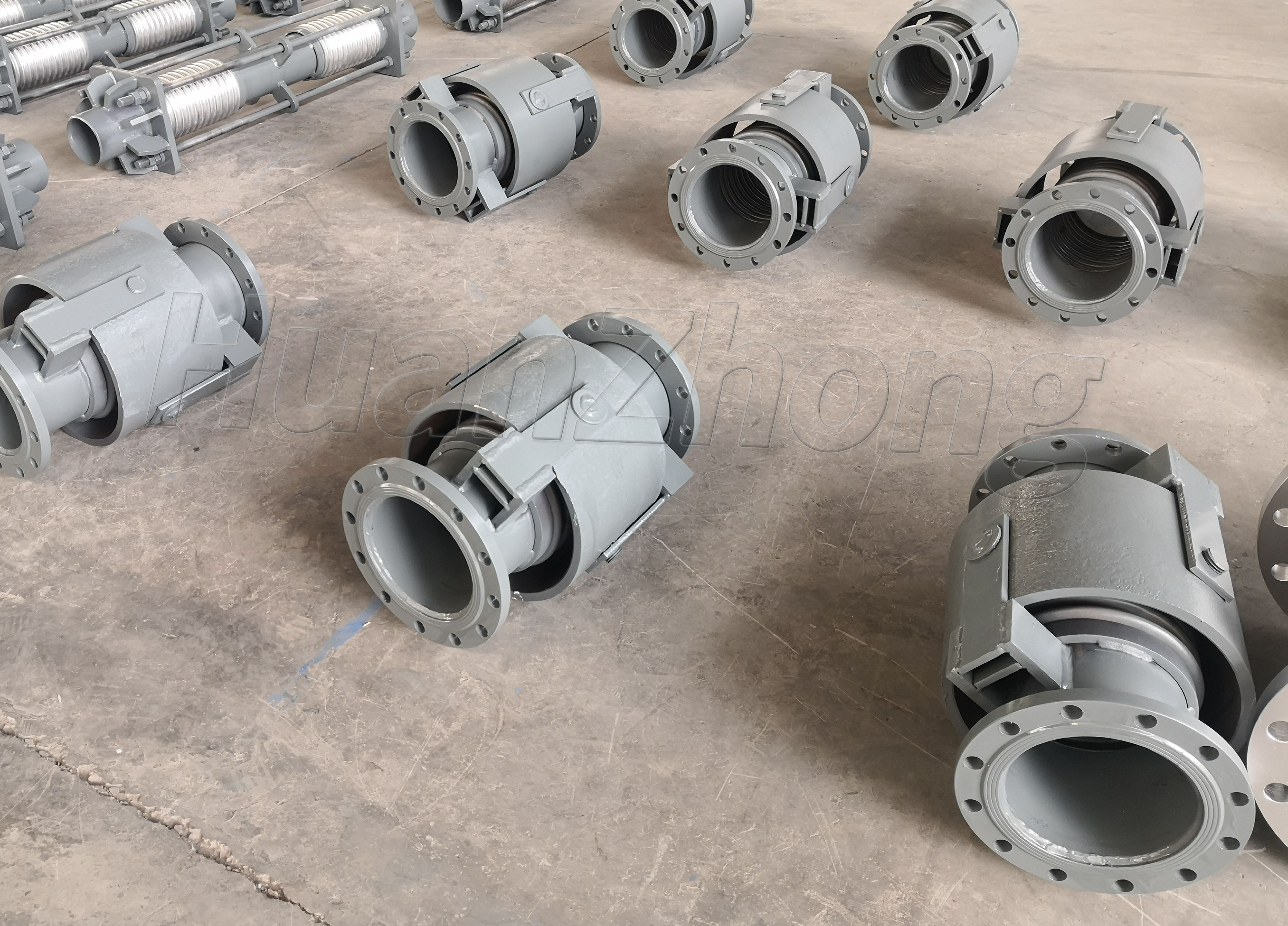

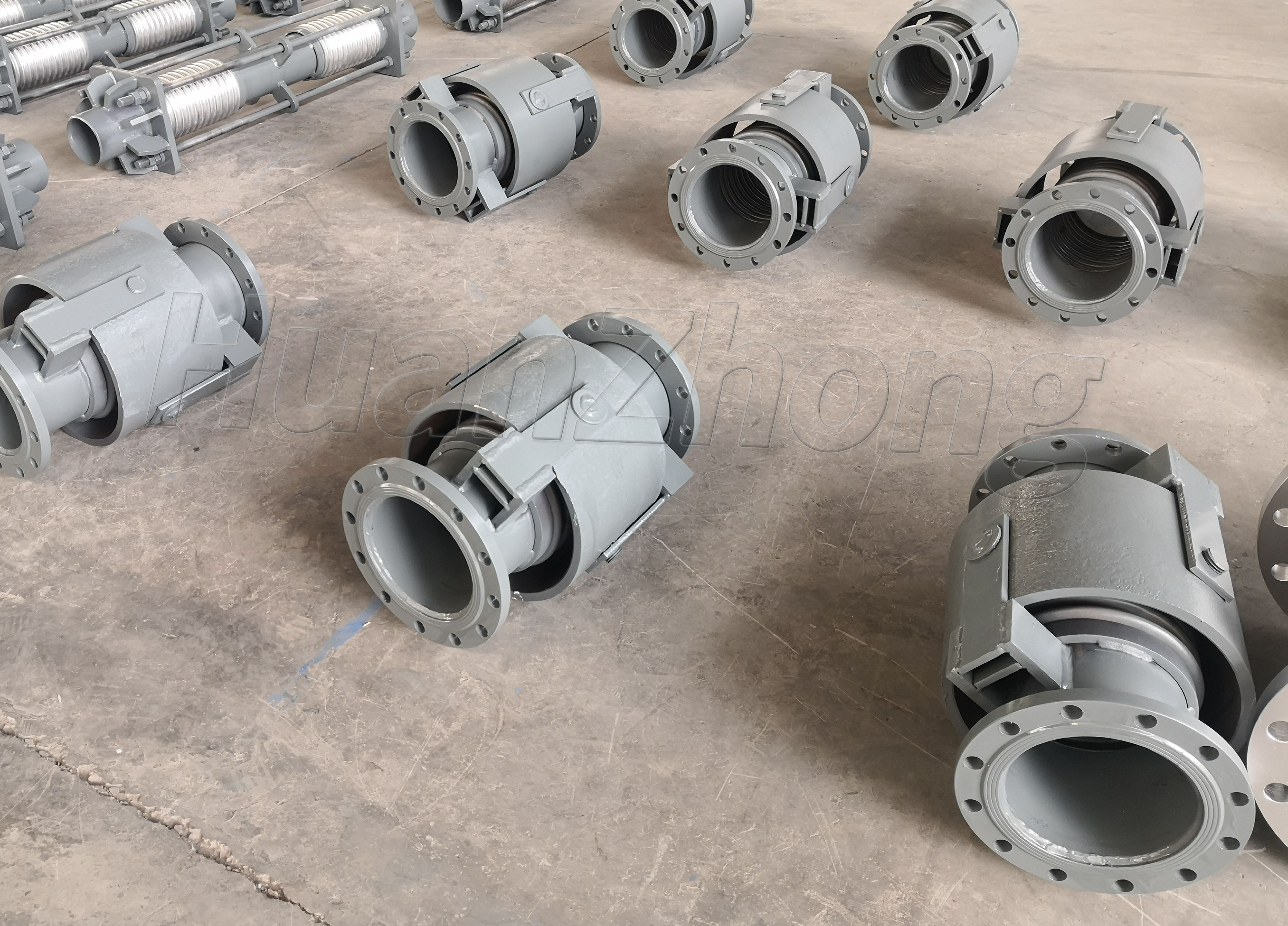

Corrugated compensator processing process

Corrugated compensator processing process

Corrugated compensator in the molding process, the material occurs cold work hardening phenomenon, the strength will be strengthened, the corrugated pipe pressure-bearing capacity increased. However, because the corrugated compensator is split installation, higher formation stress, it is difficult to ensure the waveform shape of the corrugated compensator after splitting. The corrugated compensator must be processed to eliminate stress.

Corrugated compensator wire cutting processing in order to reduce the size of the joints, all parts of the split processing, are used wire cutting process. Line cutting money, first mark, then line cutting, cut and assembled together, in order to facilitate on-site grouping. Compensation alignment corrugated compensator line cutting, should be grouped together again, along the side of the three butt longitudinal seams are spot welded alignment liner, and mark, and then separate, grinding from the welded bevel.

Metal corrugated compensator engineering many applications and the use of the expanding range of compensators require outstanding compensation ability, corrugated pipe wall thickness should be thin rather than thick, but in order to meet the requirements of accepting internal pressure, the general choice of multi-layer structure. Metal bellows compensator, also known as metal bellows compensator, metal bellows expansion joint, metal bellows expansion joint, is the use of bellows as an elastic element of the elastic deformation to absorb the scale of the pipeline or container because of thermal expansion and contraction, etc. This occurs in a compensation element, for pipelines, equipment and systems of heating displacement, mechanical displacement absorption and noise reduction, etc..