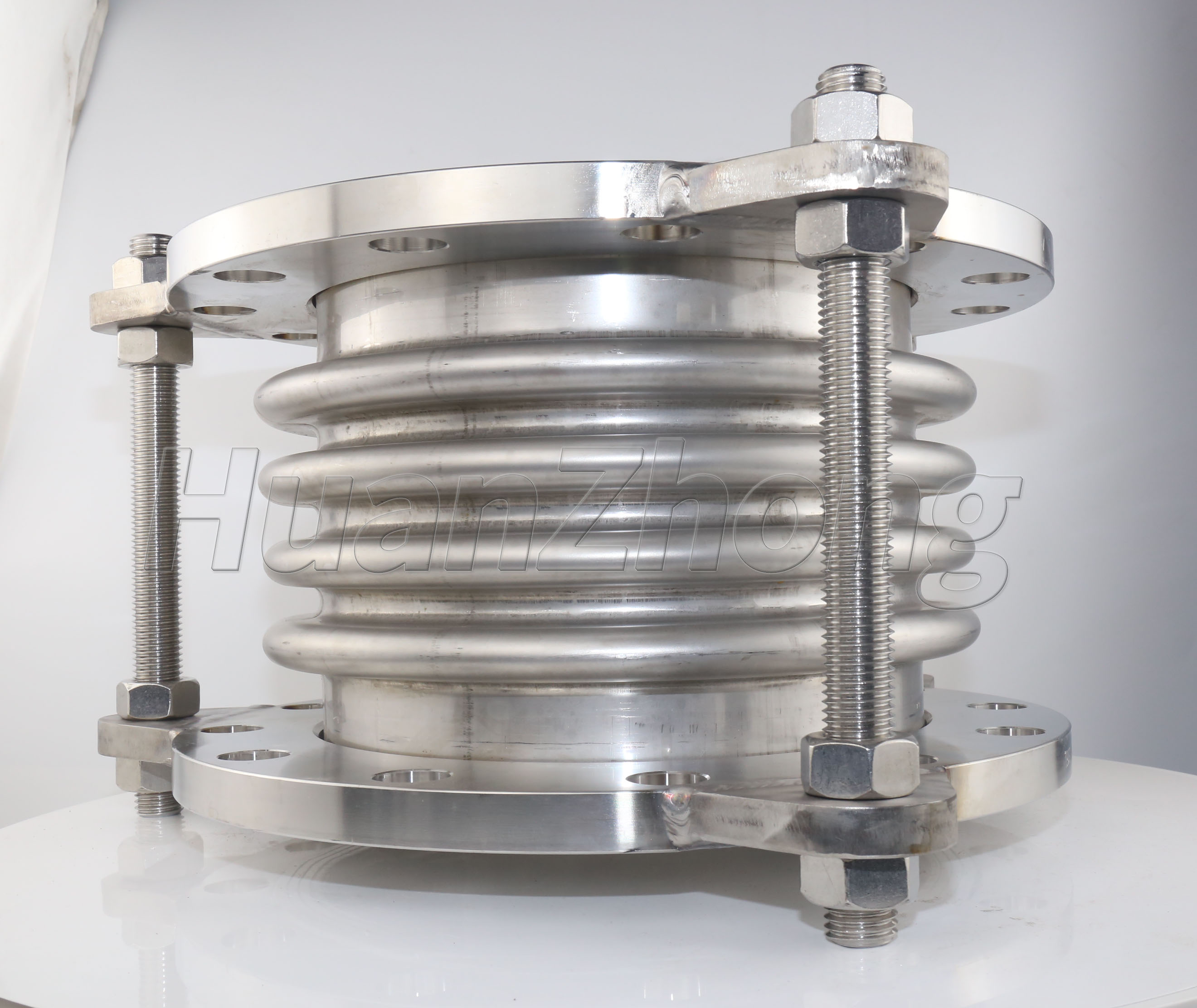

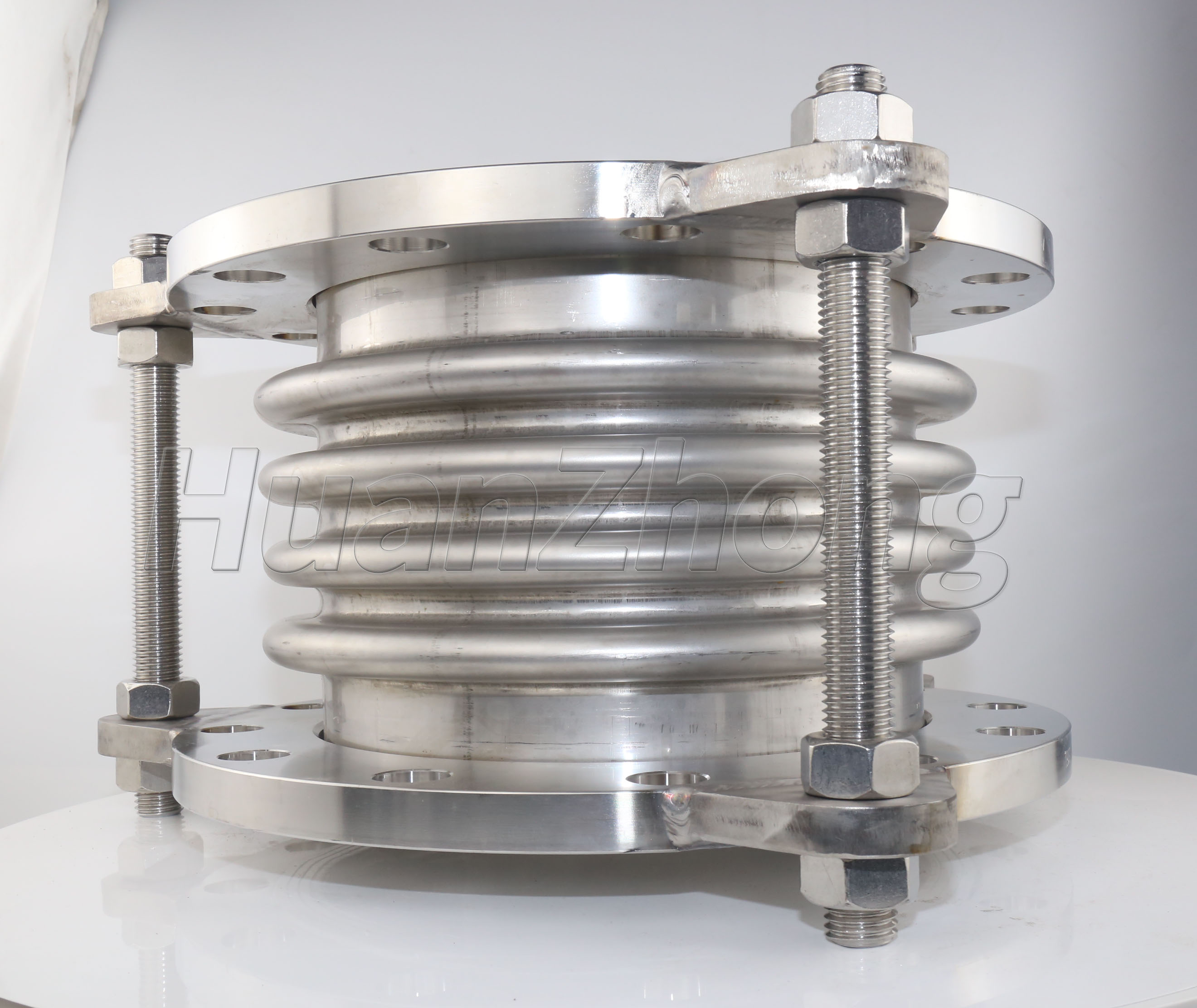

Corrugated compensator manufacturer

Corrugated compensator manufacturer

The choice of compensation form is also affected by many factors such as pipeline laying space conditions, steam requirements, pipeline engineering costs. The following in accordance with the corresponding design specifications, on the basis of thermal compensation form selection and specific layout methods and other issues, to talk about some of their own design experience. Steam pipeline compensation is divided into natural compensation and pipeline compensator compensation. At present, the commonly used thermal compensators are corrugated compensators, casing-type compensators, rotary compensators and spherical compensators. The compensator is more widely used in the actual steam pipeline.

The natural compensation of the pipeline is to use the natural bending (flexibility) of the pipeline itself to compensate for the thermal elongation of the pipeline. When the bend angle is less than 150 °, can be used as natural compensation; greater than 150 ° can not be used as natural compensation. Steam pipeline design, commonly used natural compensation L-type, Z-type, π-type and space three-dimensional bend, etc. π-type compensation, also known as square (moment) compensator, consisting of four 90 ° elbow, there are two types of horizontal π-type and vertical π-type.

Natural compensation is safe and reliable, in the terrain changes or steam pipeline bend occasions, should try to use the pipeline itself to the direction, and in the appropriate location to set the guide frame and fixed frame for reasonable setting domestic and foreign most think "Ⅱ" "Z" "L" type and other natural compensation method is relatively simple, safe and durable, so should be listed as the first choice of steam direct buried pipeline compensation program, but natural compensation is after all limited, rely on the compensator compensation is more important, foreign advocates of sleeve compensator, that it is strong resistance to vapor impact, long life, relatively low price, but the disadvantage is to regularly inject seal packing. It is said that there are improved domestic, can be injected once a few years filler, and there have been successful examples of engineering.